Custom Roller Reamer Drilling Tool Manufacturer in China

We offer Roller reamer drilling tools designed for precision and efficiency in industrial and engineering applications. Our tools provide smooth hole finishes, accurate dimensions, and enhanced durability. Ideal for metalworking, construction, and manufacturing projects, our Roller Reamers ensure reliable performance, reduce material waste, and improve overall productivity for professional and industrial use.

Sinodrills - Your Trusted Roller Reamer Drilling Tool Manufacturer from China

Your trusted Roller reaming drilling tool manufacturer from China, providing high-performance tools for precise hole finishing, smooth surfaces, and accurate dimensions. Our Roller Reamers are designed for durability and efficiency, ideal for metalworking, construction, and industrial applications. We deliver reliable, professional-grade drilling solutions to enhance productivity, reduce material waste, and meet the highest industry standards.

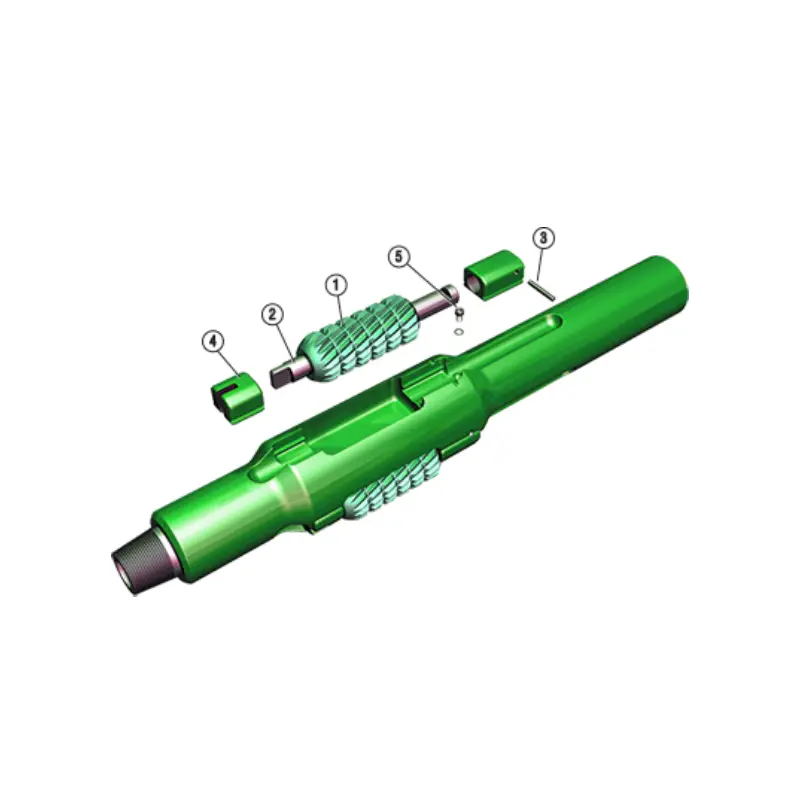

Roller Reamer Drilling Tool Components

Body: The central structural component that connects to the drill string. Made from heat-treated alloy steel, it holds all the other parts and provides the necessary strength to withstand harsh downhole conditions and drilling forces.

Cutters/Rollers: The cylindrical, cone-shaped, or spherical parts with hardened teeth or carbide inserts. They rotate to crush and remove rock, enlarging the wellbore to the desired gauge while also reducing torque and friction.

Cutter Blocks/Pins: These are the components that hold the cutters securely within the reamer body’s pockets. They are designed for easy replacement on the rig floor, allowing for maintenance without needing to send the entire tool back. * Cutter Retention System: The mechanism, often a wedge lock or cross pin, that securely holds the cutter pins in place. This system is crucial for preventing the cutters from dislodging downhole, which could lead to a stuck pipe or other non-productive time.

Roller Reamer Drilling Tool Components

High Precision Cutting – Roller reamer drilling tools achieve accurate hole dimensions with minimal deviation, ensuring tight tolerances and perfect fits for precise engineering and industrial applications.

Smooth Surface Finish – They create polished, smooth internal surfaces, reducing friction, enhancing component fit, and improving overall performance and durability in mechanical assemblies.

Durable Construction – Made from high-quality materials, roller reamers resist wear, corrosion, and deformation, providing long-lasting performance even under heavy-duty drilling conditions.

Efficient Material Removal – These tools remove minimal material while refining holes, preserving workpiece integrity and reducing waste during machining and drilling operations.

Versatile Application – Suitable for metalworking, construction, and industrial projects, roller reamers perform effectively on steel, aluminum, and other metals, delivering consistent and reliable results.

Various Roller Reamer Drilling Tool

API roller reamer drilling tool

We supply API roller reamer drilling Tools designed for precise hole finishing and smooth surfaces in industrial applications. Our tools ensure accurate dimensions, durability, and reliable performance for metalworking, construction, and manufacturing projects. We provide professional drilling solutions that enhance efficiency, reduce material waste, and meet the demanding requirements of various engineering operations.

roller reamer drill tools wholesale

We offer roller reamer drill tools wholesale, designed for precise hole finishing, smooth surfaces, and accurate dimensions. Our roller reamers provide durability and efficient performance, ideal for metalworking, construction, and industrial applications. We supply reliable drilling solutions to help you enhance productivity, reduce material waste, and achieve consistent results in every project.

roller reamer drill tools wholesale

We supply roller reaming drilling tools for oilfield applications, designed to achieve precise hole sizes and smooth finishes. Our tools ensure efficient material removal, reliable performance, and durability in demanding drilling operations, making them ideal for various oilfield projects. Trust us to provide professional solutions for your drilling and reaming needs.

roller reamer drilling tools custom

We offer custom roller reaming rrilling tools tailored to your specific project needs. Our tools provide precise hole finishing, smooth surfaces, and accurate dimensions. Suitable for metalworking, construction, and industrial applications, we supply reliable roller reamers designed to improve efficiency, reduce material waste, and ensure consistent performance for professional and industrial drilling tasks.

Customize Your Desired Roller Reamer Drilling Tool

Size and Diameter Selection

We help you choose the exact size and diameter of roller reamer drilling tools to meet your project requirements. By customizing dimensions, we ensure precise hole finishing, accurate tolerances, and compatibility with your specific drilling equipment and workpieces.

Material and Coating Options

We provide options for different tool materials and coatings to match the drilling application. By selecting the right combination, we enhance durability, reduce wear, and ensure smooth operation for various metals and industrial conditions.

Flute Design and Geometry

We customize the flute design and cutting geometry of roller reamers to optimize performance. Tailored designs improve chip removal, reduce friction, and achieve consistent, polished surfaces in holes for demanding industrial and engineering applications.

Shank and Mounting Type

We offer flexibility in shank style and mounting type to ensure compatibility with your drilling machines. By customizing this aspect, we make tool installation easier, improve stability during operation, and enhance overall efficiency and precision in drilling tasks.

what is roller reamer?

A roller reamer is a precision cutting tool used to enlarge and finish existing holes with high accuracy. Unlike standard drill bits, it focuses on refining the diameter and smoothing the internal surface, ensuring tight tolerances, reduced friction, and improved component fit.

Roller reamers are widely used in metalworking, construction, and industrial applications where precise hole dimensions and polished finishes are essential for reliable performance.

what is roller reamer made of?

Roller reamers are made from durable materials designed to withstand heavy-duty drilling and provide precise hole finishing.

The combination of base material, coatings, and cutting edges ensures long-lasting performance, smooth surfaces, and accurate dimensions, making them suitable for metalworking, construction, and industrial applications.

Materials and Features:

Tool Steel – Roller reamers are often made from high-grade tool steel, providing strength and wear resistance. We use this material to ensure the tool maintains its shape and cutting performance under repeated heavy-duty drilling operations.

Carbide Tips – Some roller reamers feature carbide tips for enhanced hardness and durability. We integrate carbide to improve cutting efficiency, resist abrasion, and allow the reamer to perform effectively on tough metals and demanding industrial applications.

Coatings – Tools may be coated with materials like TiN, TiCN, or black oxide. We apply coatings to reduce friction, increase tool life, and improve surface finish quality during reaming operations.

Alloy Materials – Certain roller reamers use alloyed steels for balanced strength and toughness. We select alloys to optimize performance, ensuring precise hole dimensions while maintaining resilience against wear and high-temperature conditions.

Shank Materials – The shank is made from durable steel or reinforced alloys. We ensure the shank is strong and stable to provide secure mounting, minimize vibration, and maintain accuracy during drilling and reaming processes.

what is roller reamer used for?

Roller reamers are used to enlarge, smooth, and finish pre-drilled holes with high precision. They ensure accurate diameters, polished surfaces, and tight tolerances.

Widely applied in metalworking, construction, and industrial projects, roller reamers enhance component fit, reduce friction, and improve overall efficiency and quality in machining operations.

Applications and Uses:

Hole Finishing – Roller reamers are used to refine drilled holes to precise diameters. We ensure smooth, polished surfaces, improving the fit of components and minimizing the need for additional finishing processes.

Industrial Machining – These tools are widely applied in industrial machining for metal and alloy workpieces. We provide roller reamers that maintain accuracy and efficiency during high-volume or heavy-duty operations.

Construction Projects – Roller reamers are used in construction to achieve precise holes in structural materials. We supply tools that deliver consistent performance, ensuring safety and structural integrity in building applications.

Automotive and Aerospace – They are critical for drilling precise holes in automotive and aerospace components. We offer roller reamers that enhance assembly accuracy and reduce wear in mechanical systems.

Custom Manufacturing – Roller reamers are applied in custom or specialized manufacturing projects requiring exact hole dimensions. We provide tailored tools to meet specific project requirements, ensuring high-quality results and reliable performance.

Send Your Inquiry Now

All-in-one Roller Reamer Drilling Tool Solutions for Your Project

We provide Roller Reamer Drilling Tool solutions for your project, offering precise hole finishing, smooth surfaces, and accurate dimensions. Our tools are suitable for metalworking, construction, and industrial applications, delivering reliable performance, improved efficiency, and consistent results to meet the specific needs of your drilling and machining projects.