Custom Rotary Steerable System Manufacturer in China

We offer precision-engineered RSS tools for complex directional drilling. Our systems, featuring both push-the-bit and point-the-bit technologies, ensure continuous rotation, faster ROP, and superior wellbore quality. We provide tailored solutions and full technical support to meet your unique well trajectory and challenging formation requirements.

Sinodrills - Your Trusted Rotary Steerable System Manufacturer from China

We deliver high-performance directional drilling tools. Our advanced RSS technology ensures continuous rotation, maximizing Rate of Penetration (ROP) and producing smoother wellbores with unparalleled steering accuracy. Choose us for reliable, cost-effective RSS solutions tailored to your complex drilling projects and challenging downhole environments.

Rotary Steerable System Benefits

Increased Rate of Penetration (ROP): Continuous rotation ensures optimal weight transfer to the bit, significantly increasing how fast the well is drilled. This reduces the time needed to reach the target depth.

Smoother, In-Gauge Wellbore: Maintaining constant rotation eliminates the ‘slide’ mode, resulting in less tortuosity and a more consistent borehole diameter. A smoother hole simplifies casing runs and logging operations.

Superior Hole Cleaning: The continuous rotation of the drill string enhances fluid circulation and turbulence in the annulus. This efficiently removes drill cuttings, reducing the risk of packing off or getting stuck.

Extended Reach Drilling Capability: Reduced drag and friction due to continuous rotation allows operators to drill much longer and more complex horizontal or extended-reach wells. This maximizes reservoir exposure.

Accurate Well Placement: RSS provides precise, closed-loop directional control with near-bit sensors. This allows for real-time steering corrections, ensuring the well stays precisely within the high-value pay zone.

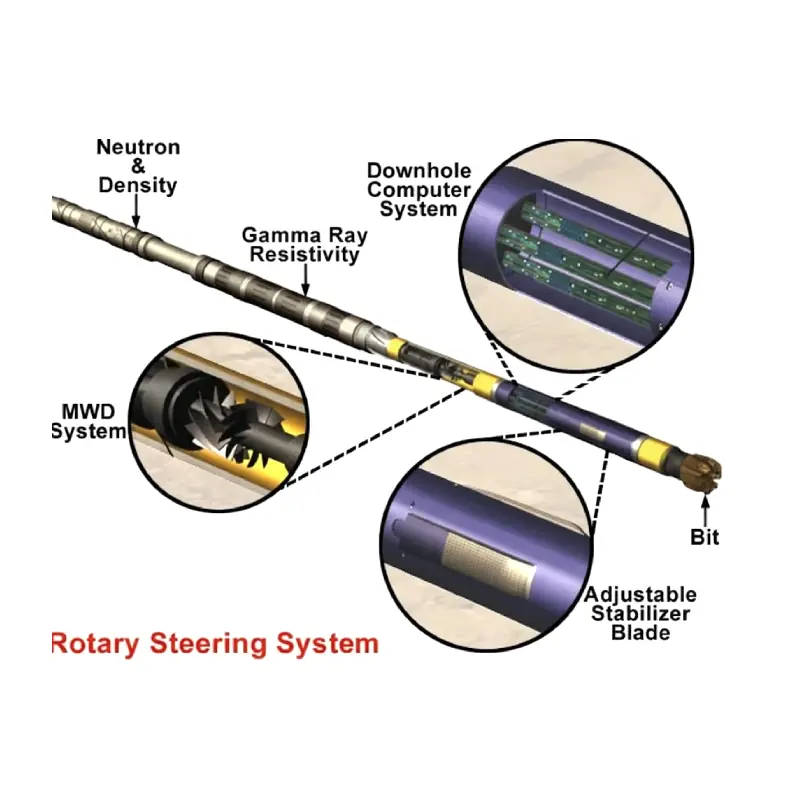

Rotary Steerable System Components

Steering Section/Mechanism: This is the core of the RSS, containing actuators or bias units that apply force to the bit or wellbore. It continuously directs the drill bit to follow the planned three-dimensional trajectory.

Directional Sensor Package: A suite of high-resolution sensors, often placed near the bit, provides real-time inclination and azimuth data. This feedback is crucial for the downhole control unit to make immediate, accurate steering adjustments.

Downhole Control Unit/Electronics: A microprocessor-based system receives data from the sensors and commands from the surface. It autonomously controls the steering mechanism, ensuring the tool stays precisely on the intended well path.

Power Supply: This unit provides the necessary electrical power for the electronics, sensors, and steering actuators. Power is typically generated downhole using a turbine driven by the drilling fluid flow.

Telemetry System (MWD/LWD): Integrated Measurement While Drilling (MWD) and Logging While Drilling (LWD) tools transmit data to the surface and receive steering commands. This two-way communication enables real-time monitoring and downlinking of new instructions.

Customize Your Desired Rotary Steerable System

Steering Technology Selection (Push vs. Point)

We customize the core steering mechanism based on your dogleg severity (DLS) and wellbore quality requirements. For high-DLS curves and rapid trajectory changes, we recommend the agile push-the-bit system. Alternatively, we use the point-the-bit design for smoother, less tortuous laterals, ensuring better weight transfer in extended reach sections.

System Size and Build Rate Capability

We tailor the tool’s diameter and mechanical limits to match your specific hole size and required trajectory curve. This customization ensures the RSS provides the necessary directional aggressiveness—from maintaining a vertical path to achieving a high build rate—while perfectly fitting the chosen drill bit and bottom-hole assembly (BHA) components.

Telemetry and Downhole Sensor Integration

We integrate your preferred Measurement While Drilling (MWD) and Logging While Drilling (LWD) sensors directly into the RSS BHA. This ensures critical data—such as gamma ray and resistivity—is measured closer to the bit, providing us with a real-time, closed-loop feedback system for highly accurate and precise geosteering into the pay zone.

Temperature Ratings

We select specialized materials and high-spec components to guarantee reliable performance in extreme downhole conditions. We ensure the RSS can withstand high bottom-hole temperatures (up to 175 ℃ and pressures, and we use abrasive-resistant alloys for longevity in challenging, abrasive formations.

what is rotary steerable System?

A Rotary Steerable System (RSS) is an advanced downhole drilling tool that enables highly accurate and efficient directional drilling by steering the drill bit while the entire drill string is in continuous rotation from the surface.

Unlike conventional steerable motor assemblies which require stopping rotation to change direction (a process called “sliding”), the RSS uses internal mechanisms (either “push-the-bit” or “point-the-bit” technology) and a closed-loop control system to adjust the well’s trajectory in real-time.

This continuous rotation significantly increases the Rate of Penetration (ROP), improves hole cleaning, reduces friction and torque, and results in a smoother, less tortuous wellbore, making it essential for complex 3D and extended-reach drilling (ERD) projects.

How Does rotary steerable System work?

The Rotary Steerable System (RSS) works by intelligently deflecting the drill bit while the entire drill string maintains continuous rotation from the surface. This innovation eliminates the need for the traditional stop-and-slide motion, ensuring constant drilling efficiency and superior wellbore quality.

The core function relies on a closed-loop system of sensors, electronics, and mechanical actuators to execute a pre-programmed well path with high precision.

The operation of an RSS is achieved through one of two primary steering methods:

Push-the-Bit Technology: This system uses external, non-rotating pads or shoes to press against the side of the wellbore at a specific orientation. This force pushes the drill bit to the opposite side, creating a continuous side-load. We control the magnitude and direction of this force to steer the well along a tight or aggressive curve as required by the directional plan.

Point-the-Bit Technology: This mechanism uses an internal deflection unit to bend the rotating drive shaft slightly, tilting the drill bit face in the desired direction. We achieve steering by continuously orienting this tilt without needing to push against the wellbore. This results in a smoother, less tortuous borehole, which is ideal for long lateral sections and extended-reach drilling.

What is Rotary steerable system used for?

The Rotary Steerable System (RSS) is primarily used in directional drilling operations to execute complex well paths with superior precision and speed. By allowing continuous rotation of the drill string while steering, the RSS overcomes the friction and efficiency drawbacks of conventional directional drilling, making it the preferred technology for challenging well trajectories and large-scale field development.

Key applications for which a Rotary Steerable System is used include:

-

Extended-Reach Drilling (ERD) Wells: The continuous rotation dramatically reduces downhole friction and drag, enabling operators to drill much longer horizontal sections. We utilize the RSS to push the total measured depth of the well further, maximizing the reservoir contact area from a single surface location.

-

Precise Geosteering and Well Placement: Integrated sensors provide real-time directional and formation data close to the drill bit, which is crucial for geosteering. The RSS is used to keep the wellbore precisely within a thin, high-value pay zone, maximizing hydrocarbon recovery and avoiding non-productive rock.

-

Drilling Complex 3D Trajectories: The system’s ability to adjust the well path continuously and autonomously is necessary for wells that require multiple simultaneous changes in inclination and azimuth. The RSS is used to drill sophisticated designer wells with complex curves and precise landing points.

-

Creating Smooth, High-Quality Wellbores: By eliminating the stop-and-slide motion, the RSS drills a smoother, less tortuous borehole. This better wellbore quality reduces wear on equipment, facilitates faster casing and logging runs, and minimizes the risk of the drill string getting stuck.

Send Your Inquiry Now

All-in-one Rotary Steerable System Solutions for Your Project

We provide tailored RSS solutions to conquer complex drilling challenges. Our systems deliver continuous rotation for superior ROP, precise well placement, and smoother wellbores, even in extended-reach applications. Partner with us for customized, reliable technology that maximizes your efficiency and reservoir exposure.