Custom Self Drilling Hollow Anchor Bars Manufacturer in China

Sinodrills specializes in the manufacturing of Self Drilling Hollow Anchor Bars. These innovative bars serve as the core component of our self-drilling anchor systems, allowing for simultaneous drilling, grouting, and anchoring in various ground conditions. Crafted from robust steel, our hollow anchor bars are designed to withstand significant torque and thrust during installation while facilitating efficient grout injection for superior bond strength and reliable ground support.

Sinodrills - Your Trusted Self Drilling Hollow Anchor Bars Manufacturer from China

Sinodrills is your trusted manufacturer of high-quality self-drilling hollow anchor bars from China. We specialize in producing robust and reliable anchor bars designed for efficient installation in diverse ground conditions. Our products, including various sizes and thread types, are engineered to provide superior load transfer and durability for geotechnical and civil engineering projects. We offer complete solutions, ensuring your projects benefit from our expertise and commitment to excellence.

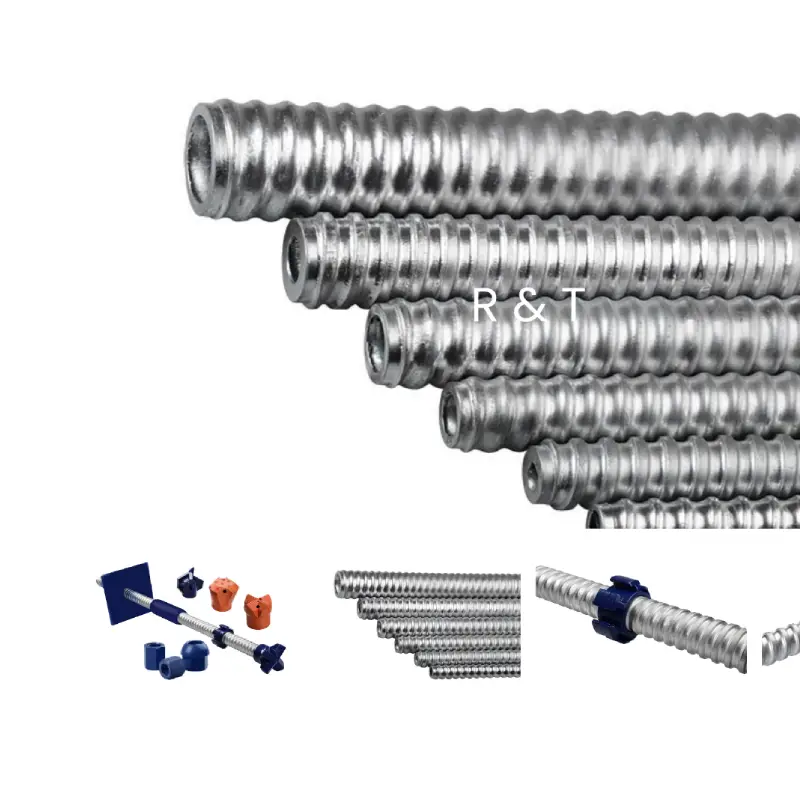

Various Self Drilling Hollow Anchor Bars

custom hollow self drilling anchor bar

Sinodrills specializes in providing custom hollow self-drilling anchor bars tailored to your exact project specifications. We understand that every geotechnical challenge is unique, which is why we offer customization in various aspects. You can specify the bar diameter and length to match load requirements and ground conditions. We also customize thread types (R or T threads) and corrosion protection coatings to ensure optimal performance and longevity. Our bespoke solutions guarantee the perfect fit for your specific anchoring needs.

galvanized self-drilling anchor hollow bars

Sinodrills offers galvanized self-drilling anchor hollow bars, providing exceptional corrosion protection for your projects. Our galvanization process applies a durable zinc coating, significantly extending the service life of the anchor in aggressive environments. These robust bars facilitate simultaneous drilling and grouting, ensuring efficient installation and reliable ground support even in challenging conditions, making them ideal for long-term applications.

metal self-drilling anchor hollow bars for mining

Sinodrills provides robust metal self-drilling anchor hollow bars specifically designed for demanding mining applications. Our high-strength bars offer exceptional performance in challenging ground conditions, ensuring reliable strata control and excavation stability. Engineered for efficient drilling and grouting in a single pass, they enhance safety and productivity in underground operations, supporting tunnels, shafts, and stopes.

wholesale hollow self-drilling anchors

Sinodrills is your trusted source for wholesale hollow self-drilling anchors. We provide a comprehensive range of anchor systems, including various diameters and lengths, along with compatible drill bits, couplers, and nuts. Our products are manufactured to stringent international standards, ensuring exceptional performance and durability for diverse geotechnical and construction applications. Partner with us for reliable and cost-effective bulk solutions.

self-drilling hollow injection anchor bolt for mining

Sinodrills provides robust self-drilling hollow injection anchor bolts specifically engineered for demanding mining applications. Our anchors offer superior performance in fractured rock and unstable ground, ensuring efficient and safe excavation support. Designed for optimal grout injection through their hollow core, they deliver reliable, high-load capacity reinforcement. We offer tailored solutions to meet the unique challenges of underground mining environments.

Customize Your Desired Self Drilling Hollow Anchor Bars

Anchor Bar Diameter and Length

The diameter and length of the hollow anchor bar are critical parameters, determined by the required load-bearing capacity and the geotechnical conditions of the site. Larger diameters offer increased strength, while length is optimized for effective anchorage within the stable ground strata.

Thread Profile (R-thread vs. T-thread)

The choice between R-thread and T-thread profiles impacts the anchor’s bonding characteristics and load transfer efficiency. R-threads provide continuous engagement, suitable for various soils, while T-threads offer a deeper, more robust profile for higher load capacities and enhanced grout bond in challenging ground.

Steel Grade and Material

The steel grade and material composition are selected based on the required tensile strength, yield strength, and corrosion resistance. High-strength steels are used for demanding applications, while specialized alloys or coatings provide enhanced durability in aggressive environments, ensuring long-term performance.

Corrosion Protection

Customized corrosion protection is essential for the longevity of the anchor, particularly in corrosive soil or water. Options include hot-dip galvanization for robust external coating, epoxy coatings for chemical resistance, or the use of stainless steel, providing superior protection against degradation over the anchor’s service life.

what are self drilling hollow anchor bars?

Self-drilling hollow anchor bars are integral components of self-drilling anchor systems, designed for efficient ground support in challenging geological conditions. These are specialized steel tubes, typically featuring external threads along their length, which allow them to serve as both a drill rod and the primary anchoring element.

Their hollow core facilitates the flushing of drill cuttings during installation and, crucially, allows for the simultaneous injection of grout, which bonds the anchor to the surrounding soil or rock. This innovative design streamlines the installation process, making them highly effective for slope stabilization, tunneling, and foundation work.

what are self drilling hollow anchor bars used for?

Self-drilling hollow anchor bars are versatile components used in various geotechnical and civil engineering applications where efficient and reliable ground support is critical. Their design allows for simultaneous drilling and grouting, making them particularly effective in challenging or unstable ground conditions.

- Slope Stabilization: Used to reinforce unstable slopes and embankments, preventing erosion and landslides in infrastructure projects.

- Tunneling and Mining: Provide immediate ground support for tunnel faces, roofs, and walls, enhancing safety and stability during excavation and operation.

- Micropiles and Foundation Underpinning: Employed as micropiles or for underpinning existing foundations, offering robust load-bearing capacity in areas with weak or variable soils.

- Retaining Walls: Crucial for anchoring retaining structures and providing temporary or permanent support for deep excavations.

- Temporary Support: Often utilized for rapid deployment in temporary ground support systems due to their quick installation.

how to use self drilling hollow anchor bars?

Using self-drilling hollow anchor bars simplifies installation by combining drilling and grouting. This method provides efficient and reliable ground support for various construction and geotechnical applications, ensuring robust performance.

Step 1: Prepare the Site and Equipment

Before commencing, ensure the work area is clear and safe. Position the drill rig accurately at the designated anchor location. Verify that all components, including the self-drilling hollow anchor bar, sacrificial drill bit, and grouting equipment, are in good working order and readily accessible.

Proper preparation ensures a smooth and efficient installation. Attach the appropriate drill bit to the anchor bar. Confirm the grouting system is connected and primed, ready to deliver grout as drilling progresses, preventing delays in the process.

Step 2: Drill the Anchor Hole

Initiate drilling, allowing the self-drilling hollow anchor bar to penetrate the ground. The sacrificial drill bit efficiently cuts through soil or rock. Maintain consistent pressure and rotation to ensure the anchor advances steadily and accurately to the desired depth.

As drilling proceeds, continuously inject grout through the hollow core of the anchor bar. This simultaneous grouting stabilizes the borehole, prevents collapse in unstable ground, and ensures proper bonding between the anchor and the surrounding geological formation.

Step 3: Grout the Anchor

Once the design depth is reached, continue pumping grout through the anchor bar until the bore is completely filled and grout refusal is achieved. This ensures a strong, void-free bond with the surrounding ground, maximizing the anchor’s load-carrying capacity.

Allow the grout to cure fully according to specifications. The curing time is crucial for the grout to gain its intended strength, which is essential for the anchor’s long-term performance and the structural integrity of the supported element.

why choose our self drilling hollow anchor bars?

Our self-drilling hollow anchor bars are trusted solutions for a wide array of demanding geotechnical and construction applications, primarily due to their integrated functionality and robust design.

They eliminate the need for separate drilling and grouting steps, significantly enhancing project efficiency and reducing installation time. This all-in-one approach is especially beneficial in challenging ground conditions where borehole stability is a concern, ensuring a secure and reliable anchorage every time.

- Unstable Ground: Perfect for loose soils, fractured rock, and collapsing boreholes, as they stabilize the hole during drilling.

- Time-Sensitive Projects: Their rapid, simultaneous drilling and grouting drastically cuts down on installation time and labor costs.

- Limited Access Sites: The ability to extend bars with couplers makes them ideal for confined or challenging work areas.

- Permanent and Temporary Support: Used across various applications, from long-term slope stabilization to temporary excavation support.

Send Your Inquiry Now

All-in-one Self Drilling Hollow Anchor Bars Solutions for Your Project

Sinodrills provides comprehensive, all-in-one self-drilling hollow anchor bar solutions for your project. We offer a full range of components including hollow bars, specialized drill bits, couplers, and nuts, ensuring seamless integration. Our tailored systems are designed to meet diverse geological challenges, guaranteeing optimal performance and simplifying your construction processes with reliable ground support.