Slope instability poses significant challenges to infrastructure and safety worldwide. Traditional stabilization methods can be time-consuming and complex, especially in difficult terrains. This blog explores how self-drilling anchors are fundamentally changing these techniques, offering a more efficient and reliable approach to securing unstable ground.

The advent of self-drilling anchors marks a significant leap forward in geotechnical engineering. Their unique design allows for simultaneous drilling and grouting, making them exceptionally effective in various soil and rock conditions. This innovation is not just about speed, but also about enhancing the long-term integrity of critical slopes.

What is Slope Stabilization

Slope stabilization refers to a range of engineering techniques and practices designed to enhance the stability of natural or artificial slopes, preventing or mitigating landslides, erosion, and other forms of mass movement.

It involves altering the physical, mechanical, or hydrological properties of the slope to increase its resistance to failure. Slope stabilization methods can include reducing the driving forces (e.g., by regrading or removing material) or increasing the resisting forces (e.g., through drainage improvements, retaining structures, soil nailing, or the installation of anchors like self-drilling anchors), ultimately ensuring the long-term safety and integrity of the landform.

Slope Stabilization Methods

Slope stabilization employs a variety of methods to ensure the long-term integrity of natural and engineered slopes, chosen based on the specific geological conditions, slope geometry, and potential failure mechanisms. These techniques can broadly be categorized into slope stabilization methods that reduce driving forces or increase resisting forces, often used in combination for optimal results.

- Vegetation and Bioengineering: Utilizing plants, trees, and other natural materials to protect the soil surface from erosion, improve soil cohesion through root systems, and regulate moisture content within the slope, offering an environmentally friendly and aesthetic solution for shallower slopes.

- Drainage Systems: Implementing surface and subsurface drainage features, such as trenches, sub-drains, and weep holes, to control and divert water, thereby reducing pore water pressure within the slope, which is a common trigger for instability.

- Retaining Structures: Constructing walls, gabions, or buttresses at the toe of a slope to provide physical support and resist outward movement of soil or rock, effectively increasing the resisting forces against potential failure.

- Soil Nailing: Installing passive steel bars (nails) into the slope face, which are then grouted in place. These nails create a reinforced block of soil, enhancing its shear strength and overall stability by transferring tensile and shear forces.

- Anchoring Systems (e.g., Self-Drilling Anchors): Employing active or passive anchors, like self-drilling anchors, which are drilled into the slope and tensioned or grouted to provide direct resistance to movement, effectively tying the unstable mass back to more stable ground.

- Geosynthetics: Incorporating geotextiles, geogrids, or geomembranes within the slope to reinforce the soil, provide separation, filter drainage, or act as barriers, improving the overall mechanical properties and stability of the ground.

Why Slope Stability is Important

Slope stability is of paramount importance across various domains due to its direct impact on safety, infrastructure, and environmental well-being. Unstable slopes pose significant risks, leading to catastrophic failures that can result in loss of life, extensive property damage, and severe economic disruption. Ensuring slope stability is therefore not merely a technical consideration but a critical aspect of responsible engineering and land management.

- Safety of Life: The most critical reason for slope stability is to prevent landslides and rockfalls that can directly endanger human lives, homes, and communities, especially in mountainous or hilly regions.

- Protection of Infrastructure: Unstable slopes can severely damage roads, railways, buildings, pipelines, and other vital infrastructure, leading to costly repairs, service interruptions, and long-term economic setbacks.

- Environmental Preservation: Slope failures can cause widespread soil erosion, siltation of waterways, habitat destruction, and alter natural landscapes, impacting ecosystems and biodiversity significantly.

- Economic Impact: Landslides and slope failures can lead to immense financial losses from property destruction, disruption of trade routes, reduced agricultural productivity, and the high costs associated with emergency response and reconstruction efforts.

- Sustainable Development: For sustainable urban planning and resource development, understanding and mitigating slope instability is crucial to ensure that construction and land-use practices do not create future hazards, promoting long-term resilience.

Rock Bolts for Slope Stabilization

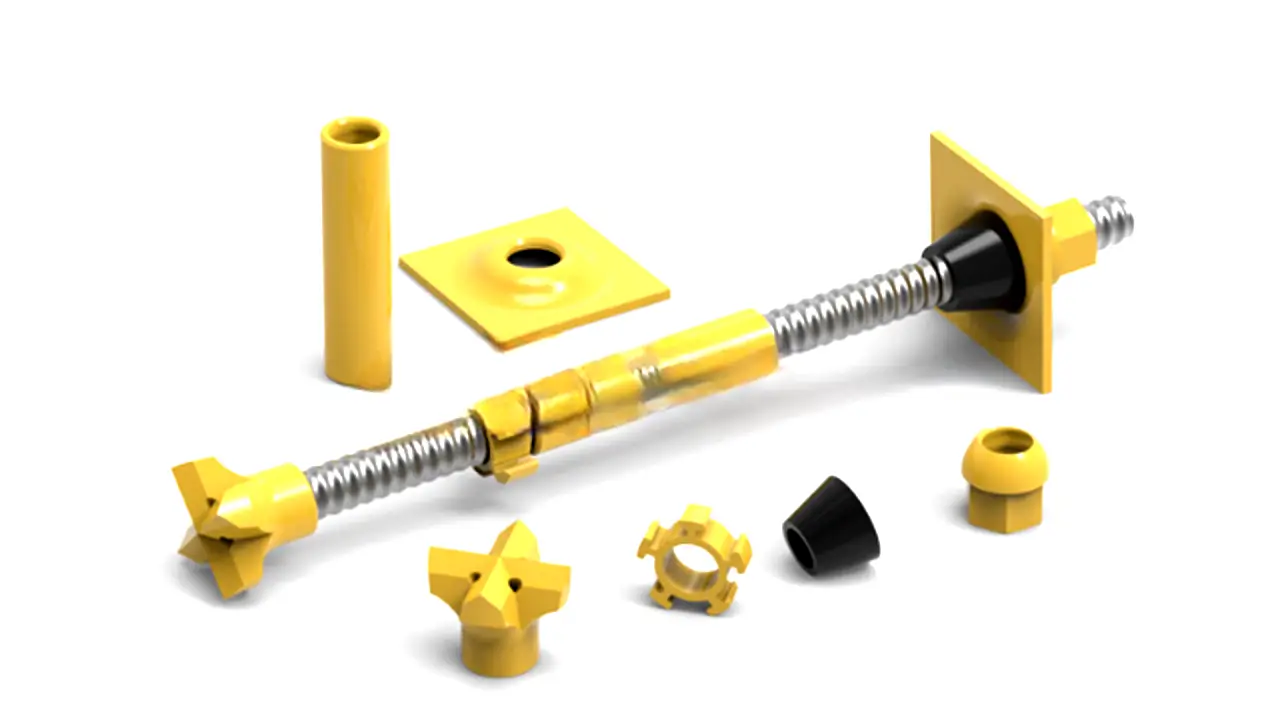

Recommended Self Drilling Anchors

Rock bolts are fundamental in reinforcing unstable rock slopes, providing essential support to prevent failures and enhance overall stability. These engineered components actively or passively transfer tensile and shear forces within the rock mass, effectively binding fractured or loose rock blocks together.

Here delves into their critical role, particularly highlighting how self-drilling anchors for slope stabilization offer advanced and highly efficient solutions in a wide range of challenging geological conditions, ultimately improving safety and project timelines.

Types of Rock Bolts

The selection of rock bolt type is crucial and depends heavily on specific geological conditions, the anticipated loads, and the project’s longevity requirements. Mechanical anchor bolts use expansion shells to grip the borehole wall, providing immediate support, while grouted dowels are fully encapsulated in grout, developing a bond along their entire length for long-term stability.

Cable bolts, often consisting of multiple high-strength steel strands, are used for very large unstable rock masses where higher load capacities are required. Each type offers distinct advantages, necessitating careful consideration during the design phase to match the bolt’s performance to the rock mass behavior.

Benefits of Self-Drilling Rock Anchors

Self-drilling rock anchors have become an indispensable tool in modern geotechnical engineering, offering a streamlined and highly efficient solution for slope stabilization and tunneling. This technology simplifies complex tasks, providing significant advantages over traditional anchoring methods.

Integrated Drilling, Grouting, and Anchoring

A key benefit of self-drilling rock anchors is their all-in-one functionality. The hollow anchor rod serves as the drill bit, the drill pipe, and the final anchor element. This eliminates the need for a separate drilling process, as the anchor is installed as the hole is being created. The hollow core also acts as a conduit for the grout, which is injected under pressure as the rod is being installed, ensuring the surrounding ground is stabilized from the inside out.

Versatility in Various Rock Conditions

Self-drilling rock anchors are remarkably versatile, performing effectively across a broad spectrum of geological conditions. The system can handle everything from unstable, fractured ground to hard rock. The ability to drill and grout simultaneously ensures that the borehole remains stable, preventing it from collapsing in loose or sandy soil. This adaptability removes the need for additional, time-consuming steps like pre-grouting or using casing to support the borehole walls.

Customizable Length and Flexibility

The modular design of self-drilling anchors allows for exceptional flexibility in construction. The anchor rods can be easily cut to size and connected to one another with couplers, which is particularly useful in areas with limited space or for creating very long anchors. This customizability ensures that the anchor system can be tailored to the specific depth and length required for a project, maximizing its effectiveness.

High-Efficiency Grouting

The high-pressure grouting process is a major advantage of this system. As the anchor rod is installed, the grout is pumped through the hollow core and forced out through the bit, filling every void and fracture in the surrounding rock. This creates a strong, consolidated mass that provides superior load-bearing capacity. The high pressure ensures that the grout fully encapsulates the anchor, creating a strong bond with the formation.

Self Drilling Anchor Bolt Installation Process

Installing a self-drilling anchor bolt is a streamlined process that combines drilling, grouting, and anchoring into a single operation. This method significantly reduces installation time and is particularly effective in unstable ground conditions where a pre-drilled borehole might collapse.

Step 1: Preparing the Equipment

First, attach the self-drilling anchor bit to the hollow anchor rod and connect it to a suitable drilling rig. Ensure the grout injection system is ready and filled with a mixture that is properly formulated for the specific ground conditions of your project.

Step 2: Drilling and Grouting

As the rig drills into the rock or soil, it simultaneously injects grout through the hollow center of the anchor rod. This continuous process stabilizes the borehole as it is created, preventing it from collapsing and ensuring a strong bond is formed between the anchor and the surrounding formation.

Step 3: Removing the Drill Bit

Once the anchor has reached the desired depth, the drill bit can be detached from the rod by reversing the rotation of the drill rig. This specialized bit is designed to remain in the ground, allowing for quick detachment and minimal disruption to the grout.

Step 4: Finalizing the Installation

After the drill bit is separated, a backing plate and nut are secured to the exposed end of the anchor bolt. This final step applies tension to the anchor, ensuring it is properly seated and can effectively transfer the load into the stabilized ground for maximum support.

Design Considerations

Effective rock bolt design requires a meticulous analysis of numerous factors to ensure optimal performance and safety. Engineers must thoroughly assess the rock mass properties, including its strength, deformability, and the orientation and characteristics of discontinuities such as joints, faults, and bedding planes.

Understanding the potential failure modes of the slope – whether it’s planar sliding, wedge failure, or toppling – is critical. Based on this analysis, parameters such as bolt length, diameter, spacing, and the required tensile or shear capacity are determined. The interaction between the bolt and the surrounding rock mass, the effects of water, and seismic loading must also be factored into the design to guarantee long-term stability under all anticipated conditions.

Advantages of Self-Drilling Anchors for Slope Stabilization

Self-drilling anchors offer substantial advantages, particularly when working in challenging or unstable ground conditions. A key benefit is their ability to eliminate the need for a separate casing, which prevents borehole collapse during drilling in loose soils, fractured rock, or overburden.

This integrated approach also allows for immediate and continuous grouting as the anchor advances, creating a superior bond with the surrounding ground and enhancing load transfer efficiency. The faster installation time, reduced equipment requirements, and minimized risk of borehole instability translate into significant cost savings and accelerated project schedules, making them a preferred solution for complex slope stabilization projects where efficiency and reliability are paramount.

Monitoring and Maintenance

Even after successful installation, continuous monitoring and periodic maintenance of rock bolts and the overall slope are absolutely essential to ensure their long-term effectiveness and detect any potential signs of distress or movement.

This can involve visual inspections, monitoring of load cells on tensioned anchors, extensometer readings to measure rock mass deformation, and regular surveys to track surface movements. Based on monitoring data, maintenance activities such as re-tensioning of active anchors, repairs to damaged components, or even the installation of additional bolts may be necessary to sustain the stability of the slope over its design life, adapting to changing environmental conditions or new load introductions.

Conclusion

In conclusion, self-drilling anchors have undeniably revolutionized the field of slope stabilization. Their integrated installation process, adaptability to diverse ground conditions, and superior performance make them an indispensable tool for engineers tackling complex geotechnical challenges. Embracing these advanced techniques leads to safer, more efficient, and more durable slope reinforcement solutions.

The benefits extend beyond mere installation efficiency; self-drilling anchors significantly enhance the long-term resilience of slopes against erosion, seismic activity, and heavy rainfall. Investing in these innovative anchors means investing in the enduring safety and sustainability of our infrastructure, protecting communities and assets from potential natural disasters.

For your next slope stabilization project, consider the unparalleled quality and reliability of wholesale self-drilling anchors from Sinodrills. We are committed to providing robust solutions that meet the highest industry standards, ensuring your projects achieve optimal stability and longevity. Partner with Sinodrills for superior geotechnical products.