Custom T51 Drill Rod Manufacturer in China

High-quality T51 Drill Rods are designed for top-hammer drilling applications. Made from premium alloy steel, they feature superior strength and durability, ensuring a long service life. The T51 thread provides a strong, reliable connection, minimizing downtime. Our rods are heat-treated for optimal performance in demanding rock conditions, offering excellent resistance to fatigue and wear.

Sinodrills - Your Trusted T51 Drill Rod Manufacturer from China

As a leading T51 drill rod manufacturer from China, Sinodrills specializes in rock drilling tools. Our rods are crafted from premium alloy steel with advanced heat treatment, ensuring exceptional durability and superior performance in mining, quarrying, and tunneling. We provide reliable and efficient drilling solutions to customers worldwide, minimizing downtime and maximizing productivity.

Your Leading Drill Rod Manufacturer from China

As a premier drill rod manufacturer based in China, we are dedicated to providing superior drilling tools for global industries. Our extensive range of drill rods, including T51 and other series, is manufactured using advanced techniques and high-grade materials to ensure exceptional durability and performance. We are committed to delivering reliable and cost-effective solutions to enhance your drilling operations.

T51 Drill Rod Benefits

Superior Strength: Made from high-grade alloy steel, these rods are heat-treated to achieve optimal hardness and tensile strength, making them highly resistant to bending and breaking.

Enhanced Durability: The robust construction and T51 thread design ensure a long service life, reducing the frequency of replacements and minimizing downtime.

Reliable Connection: The T51 thread provides a strong, secure connection between rods, ensuring efficient energy transfer from the drill rig to the bit. This reduces the risk of thread stripping and loosening during drilling.

Versatility: T51 drill rods are compatible with a wide range of top-hammer drilling applications, including mining, tunneling, and quarrying, making them a versatile choice for various projects.

Cost-Effective: Their long lifespan and reliable performance lead to lower operational costs over time, as there’s less need for frequent maintenance and tool replacement.

Reverse Circulation Drill Rod Applications

Superior Sample Integrity: The dual-wall design of RC rods ensures that drill cuttings are transported to the surface through the inner tube, completely sealed from the borehole walls. This minimizes contamination from different rock strata, providing a high-quality, representative sample for accurate geological analysis.

Faster Drilling Rates: RC drilling is significantly faster than traditional core drilling methods. The continuous and efficient removal of cuttings via compressed air keeps the drill bit clear of debris, allowing for higher penetration rates and reducing overall project time and costs.

Cost-Effectiveness: The combination of faster penetration rates, reduced rig time, and high sample quality makes RC drilling a highly cost-effective method. It reduces the need for expensive core handling and processing, and the durable rods require less maintenance, further lowering operational expenses.

Environmental Advantages: RC drilling is a more environmentally friendly option compared to other methods that use large amounts of water or drilling mud. It produces less waste and has a smaller footprint, making it ideal for remote or environmentally sensitive areas where water conservation is a priority.

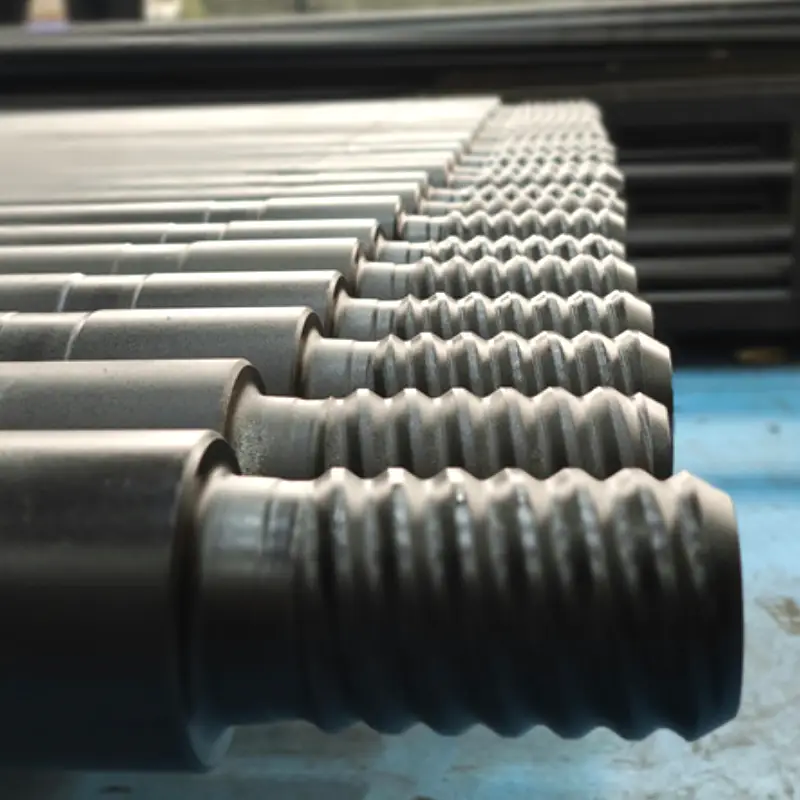

Various T51 Drill Rod

t51 drill rod for rigid connection

We offer T51 drill rods, specifically designed for rigid connections and superior performance. Manufactured from high-grade alloy steel and featuring a robust thread design, our MF (Male/Female) rods provide a more rigid drill string. This reduces thread play, leading to straighter holes, improved energy transfer, and increased drilling efficiency. Trust our T51 rods for reliable, high-performance drilling.

t51 thread drill rods for rock drilling

We offer premium T51 thread drill rods specifically engineered for high-performance rock drilling. Crafted from high-grade alloy steel and subjected to advanced heat treatment, our rods provide exceptional strength and durability. The T51 thread ensures a secure connection for efficient energy transfer, maximizing drilling speed and minimizing downtime in mining, quarrying, and construction projects.

t51 drill rods and drill bits

We offer a complete range of T51 drill rods and drill bits for top-hammer drilling. Our T51 rods are crafted from high-strength alloy steel, ensuring superior durability and efficient energy transfer. The T51 drill bits, featuring various button shapes and face designs, are engineered for optimal performance in diverse rock formations, including both soft and hard rock.

t51 integral drill rods

Our T51 integral drill rods are engineered for exceptional performance in rock drilling. Forged from alloy steel and precision heat-treated, these rods offer superior strength, durability, and fatigue resistance. The seamless T51 thread design ensures a reliable connection, maximizing energy transfer and drilling efficiency. Ideal for mining, quarrying, and construction, our rods are designed to withstand the toughest conditions.

t51 forging round drill rods

We offer premium T51 forging round drill rods, engineered for top-hammer drilling. Manufactured from high-grade alloy steel, these rods undergo a precise forging and heat-treating process for superior strength and fatigue resistance. The robust design and reliable T51 thread ensure efficient energy transfer, minimizing downtime and maximizing productivity in demanding rock drilling applications.

t51 drill rod for underground drilling

Our T51 drill rods are specifically engineered for demanding underground drilling applications. Made from premium alloy steel, they undergo a specialized heat treatment process to maximize strength and durability. The robust T51 thread design ensures a secure, reliable connection, which is crucial for efficient energy transfer and reducing downtime in long-hole drilling, tunneling, and mining operations.

Customize Your Desired T51 Drill Rod

Material and Manufacturing

We use premium-grade alloy steel and employ advanced CNC machining to craft our T51 drill rods. A meticulous heat treatment process enhances their hardness and strength, ensuring exceptional durability and resistance to wear and tear in demanding rock drilling environments.

Thread and Connection

Our T51 drill rods feature a precisely engineered thread design, providing a strong, reliable connection. We ensure an excellent fit to prevent thread stripping and minimize energy loss during impact drilling, which is crucial for maximizing drilling efficiency and safety.

Performance and Durability

We guarantee superior performance in tough drilling conditions. The combination of high-quality materials and robust design ensures our T51 drill rods resist fatigue and breakage, offering a long service life and reducing operational downtime for your projects.

Quality Control and Testing

Before our T51 drill rods reach you, they undergo rigorous quality control and testing. We perform inspections for material composition, thread integrity, and hardness, ensuring every rod meets our strict standards for reliability, performance, and safety in the field.

What does "T" mean in drill rod?

In the rock drilling, the “T” in a drill rod designation like T51 stands for trapezoidal thread.

It refers to a specific type of thread profile that’s designed for high-impact drilling applications. Trapezoidal threads are known for their large, flat surfaces and robust design, which allow for efficient transfer of percussive energy from the drill rig to the drill bit.

This thread type is particularly effective at withstanding the immense forces involved in top-hammer drilling, making it a common choice for extension drill rods used in mining, quarrying, and tunneling. Other thread types, such as “R” for round threads, are also used in the industry, each suited to different drilling conditions and power levels.

How Many Types of T Type Drill Rods Are There?

Based on the information available, there are several types of T-type drill rods, with the “T” referring to the trapezoidal thread profile. These are primarily categorized by their thread size and design, which are optimized for different drilling applications and rock conditions.

The most common types include:

T38 drill rods: These are a widely used size, often found in mining, construction, and geological exploration. They can come in two main types: “Male-Male” (MM) rods with male threads on both ends, and “Male-Female” (MF) rods, also known as speed rods, which have a male thread on one end and a female thread on the other. MF rods allow for faster rod connections without the need for a separate coupling sleeve.

T45 drill rods: These are larger than T38 and are designed for heavier drilling applications that require more power and a larger hole diameter.

T51 drill rods: As a larger thread size, T51 drill rods are used for heavy-duty drilling in hard rock, such as in large-scale mining and tunneling operations. They are built for maximum durability and efficient energy transfer.

The specific type of T-thread drill rod used depends on the project’s requirements, including the type of rock, the desired hole size, and the power of the drilling rig.

Drill Rod Specifications

Drill rod specifications can vary significantly depending on the intended application, such as rock drilling, oil and gas exploration, or general tool and machinery manufacturing. However, there are some key characteristics that are consistently used to define and classify them.

Materials and Heat Treatment

Drill rods are typically made from alloy steels that are chosen for their superior strength, hardness, and wear resistance. Common materials include:

Alloy Steels: Such as AISI 4140 or 4340, which offer excellent toughness and fatigue resistance after heat treatment.

Tool Steels: Grades like O1, W1, A2, D2, and S7 are known for their exceptional hardness and abrasion resistance. The material undergoes a controlled heat treatment process, which can include air-hardening, oil-hardening, or water-hardening, to achieve the desired properties.

Dimensions

The physical size of a drill rod is a critical specification.

Diameter: The outer diameter (OD) is a key factor and can range from small sizes (e.g., 20mm) for light applications to very large diameters (e.g., over 152mm) for heavy-duty drilling. The inner diameter (ID) is also important for applications that involve flushing fluids or retrieving core samples.

Length: Standard lengths for rock drilling rods can range from less than a meter to over 6 meters. Longer rods are used for deeper holes to reduce the number of connections, while shorter rods are used for shallower drilling or in confined spaces.

Threading

The thread profile is crucial for connecting rods and transmitting energy from the drill rig to the bit. Common thread types are:

Trapezoidal (T-type): T38, T45, and T51 are common examples, known for their robust design and use in top-hammer drilling.

Round (R-type): Such as R22, R25, and R32.

API (American Petroleum Institute) Threads: These are standard in the oil and gas industry and include types like API Regular and API Internal Flush (IF).

Send Your Inquiry Now

All-in-one T51 Drill Rod Solutions for Your Project

We offer all-in-one T51 drill rod solutions tailored for your project’s success. Our comprehensive range includes T51 drill rods, bits, and couplings, all manufactured to exacting standards. With a focus on durability and performance, our solutions ensure optimal energy transfer and exceptional penetration rates, minimizing downtime and maximizing productivity on every job.