Air Core (AC) drilling is a widely used and highly effective method in the world of mineral exploration, particularly valued for its efficiency and cost-effectiveness in certain geological conditions. This technique employs compressed air to extract geological samples, offering a rapid way to assess subsurface materials. Understanding AC drilling is crucial for anyone involved in early-stage mineral exploration projects.

Unlike some other drilling methods, AC drilling is specifically designed for shallower depths and unconsolidated ground, such as weathered rock, sands, and clays. Its ability to provide relatively uncontaminated samples quickly makes it an indispensable tool for initial geological surveys and for defining potential resource areas before more intensive drilling begins.

What is Air Core Drilling?

Air Core (AC) drilling is a rotary drilling method primarily used in mineral exploration for shallow, unconsolidated ground conditions such as weathered rock, clays, and sands. It operates by using a drill bit with steel or tungsten carbide blades, which rotates and cuts into the ground.

Compressed air is then pumped down the drill rods, and this air, along with the rock cuttings (chips), is forced back up an inner tube within the drill string to the surface. This “air core” extraction process minimizes contamination from the borehole walls, providing relatively clean and representative samples quickly and cost-effectively, making it ideal for initial geological assessment and defining potential areas of mineralization.

How Does Air Core Drilling Work?

Air Core (AC) drilling operates on a rotary principle, using a specialized drill rig to advance a drill string into the ground. At the business end of the string is a three-bladed steel or tungsten carbide drill bit, designed to cut through unconsolidated materials like weathered rock, clay, and sand. As the bit rotates and applies downward pressure, it breaks up the formation into small cuttings.

- Compressed Air Delivery: Simultaneously, compressed air is pumped down the annulus (the space between the outer drill rod and the inner sample tube).

- Cuttings Uplift: This high-pressure air then travels to the drill face, picking up the newly generated rock cuttings.

- Reverse Circulation: The air, carrying the cuttings, is then forced to return up through the central inner tube of the drill string due to the differential pressure. This “reverse circulation” ensures a continuous flow of sample material to the surface.

- Sample Collection: Once at the surface, the air and cuttings mixture is directed through a cyclone, which separates the solid rock chips from the air. These chips are then collected in sample bags at regular intervals (e.g., every meter), providing a continuous geological record.

- Minimizing Contamination: The continuous upward flow of cuttings within the inner tube, coupled with the positive pressure from the compressed air, helps to minimize contamination from the borehole walls, resulting in a relatively clean and representative sample.

What is Air Core Drilling Used For?

Air Core (AC) drilling is a highly effective and cost-efficient method predominantly used in the mining and exploration industries, particularly where ground conditions are soft or weathered. Its ability to provide quick and relatively uncontaminated samples makes it invaluable for initial assessments.

- Mineral Exploration: AC drilling is widely used for first-pass exploration programs to identify potential mineral deposits. It helps geologists understand the underlying geology, identify target areas, and define the presence of mineralization in a cost-effective manner before committing to more expensive drilling methods.

- Regolith Sampling: This method is excellent for drilling through and sampling the regolith, which is the layer of loose, heterogeneous material covering solid rock. Understanding the regolith is crucial for detecting geochemical anomalies that may indicate underlying ore bodies, as minerals often weather and disperse within this layer.

- Geochemical Sampling: AC drilling is employed to collect samples for geochemical analysis. The relatively uncontaminated samples allow for accurate measurement of elemental concentrations in the soil and rock, helping to map out geochemical patterns that can lead to new mineral discoveries.

- Environmental Studies: In environmental applications, AC drilling is used to collect soil samples for contamination assessments or to install shallow groundwater monitoring wells. Its ability to provide clean samples is critical for accurate environmental analysis and remediation planning.

- Shallow Resource Definition: While not as precise as core drilling for detailed resource estimation, AC drilling can be used in some cases for preliminary resource definition in shallow, unconsolidated deposits where high-resolution core samples are not strictly necessary.

Drilling Tools Needed for Air Core Drilling

Effective Air Core (AC) drilling operations rely on a specific array of robust and specialized tools, each playing a crucial role in creating the precise and stable holes required. The selection of these tools is largely dependent on the geological conditions of the drilling site, as different soil types and rock formations necessitate varying equipment for optimal performance and efficiency.

AC Drill Rigs

These are the core machines that provide the power and rotational force for AC drilling. AC rigs are typically smaller and lighter than RC rigs, often mounted on trucks or tracks for mobility. They are designed to efficiently handle the shallower depths and softer ground conditions characteristic of AC drilling projects.

AC Drill Rods (Dual-Tube)

Recommended Drill Rods for AC Drilling

A defining feature of AC drilling, these are specialized drill rods composed of an outer tube and an inner tube. The outer tube provides structural integrity and transmits rotational force, while the inner tube acts as the conduit for the return of air and cuttings to the surface, maintaining sample integrity.

AC Drill Bits

Recommended Air Core Drill Bits

These are the cutting tools at the bottom of the drill string. AC drill bits typically feature robust steel or tungsten carbide blades designed to efficiently cut through unconsolidated materials like clays, sands, and weathered rock. Their design allows for effective penetration while minimizing the creation of fine dust.

Compressors

Powerful air compressors are essential for AC drilling, providing the high-volume, high-pressure air necessary to flush the cuttings from the borehole. The size and capacity of the compressor are critical to ensure efficient sample return and to overcome any downhole pressure variations.

Cyclones and Sample Splitters

These are surface equipment used to process the returned air and cuttings. Cyclones separate the solid rock chips from the air stream, directing them into collection containers. Sample splitters are then used to reduce the bulk sample into a smaller, representative portion for laboratory analysis, ensuring accurate geological assessment.

What is the Air Core Drilling Process

The Air Core (AC) drilling process is a systematic procedure designed to efficiently extract geological samples from shallow, unconsolidated formations. It combines mechanical cutting with pneumatic sample recovery, making it a fast and economical method for initial exploration.

Step 1: Site Preparation and Rig Setup

The initial phase involves thoroughly surveying and preparing the drill site, ensuring it is clear of obstructions and safe for operations. Following this, the Air Core drill rig, typically a truck or track-mounted unit, is meticulously positioned directly over the planned drilling location to ensure accurate hole placement.

This meticulous setup is crucial for the efficiency and safety of the entire drilling operation. Proper positioning ensures the drill bit enters the ground precisely where intended, aligning with geological targets and minimizing any potential for deviation during the drilling process.

Step 2: Drilling and Cutting Action

Once the rig is positioned, the AC drill bit, equipped with steel or tungsten carbide blades, is lowered to the ground. The drill then begins to rotate and apply downward pressure, effectively cutting and breaking up the unconsolidated material such as soil, clay, or weathered rock at the bottom of the borehole.

This cutting action creates small rock chips or “cuttings” from the formation. The drill operator carefully controls the rotational speed and downward force to optimize penetration rates and ensure the production of consistent, manageable sample sizes for subsequent collection.

Step 3: Sample Return (Reverse Circulation of Air)

As the drill bit cuts into the ground, compressed air is simultaneously injected down the drill rods, but outside the inner tube. This high-pressure air then travels to the drill face and picks up the newly generated rock cuttings from the bottom of the hole.

The air and cuttings are then forced to travel back up through the central, inner tube of the drill rod to the surface. This unique “reverse circulation” mechanism is key to AC drilling, as it minimizes contamination from the borehole walls and delivers a relatively clean sample stream.

Step 4: Sample Collection and Logging

Upon reaching the surface, the air and cuttings mixture is directed through a cyclone or a splitter. The cyclone separates the solid rock cuttings from the air, causing the sample material to drop into collection bags or containers.

These collected samples are then systematically labelled with their corresponding depth interval, allowing geologists to accurately log the lithology, mineralogy, and any signs of mineralization. This organized collection is vital for subsequent laboratory analysis and geological interpretation.

Air Core vs RC Drilling

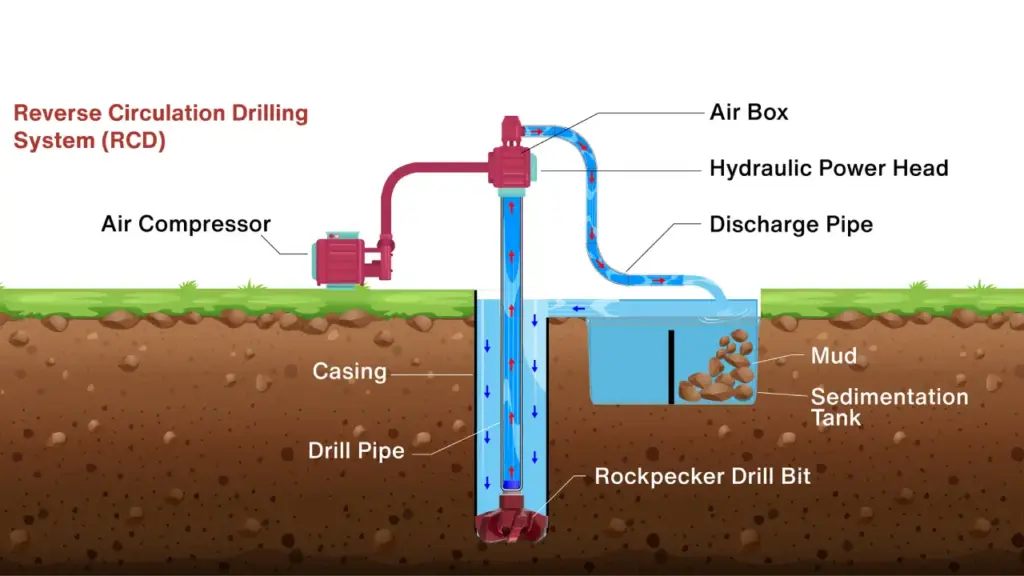

Both Air Core (AC) and Reverse Circulation (RC) drilling are crucial techniques in mineral exploration, leveraging compressed air to retrieve samples. While they share this common principle, their distinct design and operational methodologies make them suitable for different geological conditions and exploration objectives. Understanding their differences is key to selecting the appropriate drilling method.

Depth Capability

Air Core drilling is typically limited to shallower depths, generally reaching up to 100-200 meters. This limitation is primarily due to the less robust nature of the drill string and its inability to effectively penetrate hard rock formations, making it ideal for surficial exploration and regolith sampling.

Reverse Circulation drilling, conversely, is capable of reaching significantly greater depths, often exceeding 500 meters, and in some cases, even over 1000 meters. Its robust downhole hammer and sturdy drill rods are specifically designed to penetrate harder rock formations efficiently.

Sample Quality and Contamination

Air Core drilling generally provides relatively uncontaminated samples, especially in soft, unconsolidated ground, because the cuttings are brought up rapidly through an inner tube. However, in fractured or wet conditions, there can be some minor cross-contamination or loss of fine material.

Reverse Circulation drilling is renowned for delivering high-quality, continuous, and highly representative samples with minimal contamination. The dual-walled pipe system and the positive pressure of the air flow effectively prevent borehole wall sloughing and contamination from higher up the hole.

Geological Conditions

Air Core drilling is best suited for softer, unconsolidated formations, such as weathered bedrock, clays, sands, and gravels. It is particularly effective in regolith environments where conventional drilling methods might struggle or be too slow.

Reverse Circulation drilling excels in a broader range of geological conditions, including hard, competent rock, fractured ground, and formations with varying hardness. Its powerful downhole hammer can efficiently break through tough lithologies.

Cost and Speed

Air Core drilling is generally a faster and more cost-effective drilling method on a per-meter basis, especially for shallower holes. Its simpler equipment and quicker penetration rates in soft ground contribute to lower operational expenses.

Reverse Circulation drilling, while more expensive per meter than AC drilling, offers a balance between cost and sample quality for deeper and harder rock conditions. It is more expensive due to the more complex equipment, higher power requirements, and specialized bits.

Applications

Air Core drilling is primarily used for early-stage exploration, regolith sampling, geochemical surveys, and shallow environmental investigations. It helps to quickly define broad target areas and understand surficial geology.

Reverse Circulation drilling is used for more advanced exploration, resource definition, grade control in active mines, and geotechnical investigations where detailed and accurate sampling of bedrock is required.

Here are the differences between AC drilling and RC drilling as follows:

| Aspect | Air Core (AC) Drilling | Reverse Circulation (RC) Drilling |

| Depth Capability | Shallower (typically up to 100-200 meters) | Deeper (often over 500 meters, sometimes >1000 meters) |

| Sample Quality/Contamination | Good, but susceptible to minor contamination in wet/fractured ground | Excellent, highly representative, minimal contamination |

| Geological Conditions | Best for soft, unconsolidated, weathered rock, clays, sands | Wide range, including hard, competent rock and fractured ground |

| Cost and Speed | Faster and more cost-effective (per meter) for shallow holes | More expensive (per meter) but efficient for deeper, hard rock |

| Applications | Early-stage exploration, regolith & geochemical sampling | Advanced exploration, resource definition, grade control, geotech |

Conclusion

In summary, Air Core drilling stands as a vital and efficient method in the early stages of mineral exploration, offering a cost-effective way to gather valuable geological data from unconsolidated and weathered ground. Its ability to produce relatively clean samples quickly allows geologists to make informed decisions about potential mineralization, guiding subsequent, more detailed exploration efforts.

The success and efficiency of any AC drilling operation depend significantly on the quality and durability of the drilling tools employed. Using robust and well-designed AC drilling tools ensures optimal performance, minimizes downtime, and contributes to accurate and reliable sample collection, which is paramount for successful exploration projects.

For all your Air Core drilling needs, look no further than Sinodrills. We offer a comprehensive selection of wholesale AC drilling tools, engineered for durability and performance in challenging conditions. Equip your operations with top-tier tools from Sinodrills to enhance efficiency and achieve superior results in your exploration endeavors.