Understanding BR in DTH hammers is essential for anyone involved in drilling operations. BR refers to a specific hammer and bit shank standard used mainly in low-pressure DTH systems. Choosing the correct BR type directly affects drilling efficiency, air consumption, and tool lifespan in water well, quarry, and mining projects.

In this blog, we break down what BR means, how BR1 and BR2 differ, and why proper hammer–bit matching matters. Whether you are sourcing equipment or optimizing drilling performance, knowing the BR standard helps you avoid compatibility issues and achieve stable, reliable drilling results.

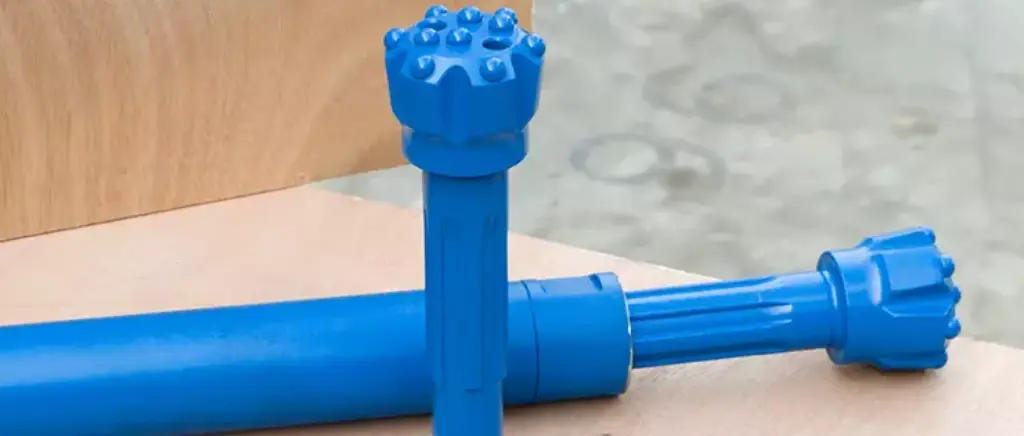

What is BR in DTH Hammers?

BR in DTH hammers refers to Bit Retaining, the system or mechanism that securely holds the drill bit inside the hammer body during operation. It prevents the bit from loosening or dropping while allowing efficient energy transfer.

A reliable BR design improves drilling stability, reduces wear, and ensures safer, more consistent down-the-hole drilling performance.

How Many Types of BR DTH Hammers?

There are three main types of BR (Bit Retaining) DTH hammers, classified by how the retaining system secures the drill bit. Each type is designed for different drilling depths, rock conditions, and operational preferences.

Understanding these BR types helps contractors select the right hammer for safety, efficiency, and bit compatibility in down-the-hole drilling projects.

- BR1 DTH Hammer: BR1 uses a simple internal retaining ring to hold the bit securely inside the hammer. It allows easy bit installation and removal, making it suitable for shallow to medium-depth drilling. This type is commonly used where quick bit changes and standard drilling stability are required.

- BR2 DTH Hammer: BR2 features a strengthened retaining structure with improved locking shoulders. It provides better resistance to vibration and impact during drilling in harder rock formations. This design enhances bit stability, reduces wear on internal components, and supports longer drilling cycles with consistent performance.

- BR3 DTH Hammer: BR3 is designed with an advanced bit-retaining mechanism for high-impact, deep-hole drilling conditions. It offers superior bit security under extreme pressure and torque. This type is preferred for mining and large-scale construction projects where durability, safety, and extended service life are critical.

How to Choose Suitable BR DTH Hammers?

Recommended DTH Hammers

Choosing a suitable BR DTH hammer depends on your rock type, drilling depth, and bit compatibility. Matching these factors ensures stable drilling performance, reduced wear, and safer operation. By selecting the right BR system for your working conditions, you can improve penetration efficiency, extend tool life, and minimize downtime in down-the-hole drilling projects.

- Rock Hardness & Formation – Select a BR DTH hammer according to rock hardness; softer formations allow lighter BR systems, while hard or abrasive rocks require stronger retaining designs to withstand impact, reduce bit loosening, and maintain consistent drilling efficiency.

- Drilling Depth & Angle – Deeper holes or angled drilling generate higher stress on the bit; robust BR hammers provide better bit retention, prevent drop-off, and maintain stability, whereas shallow vertical drilling can use standard BR types effectively.

- Bit & Equipment Compatibility – Always match the BR DTH hammer with the correct drill bit shank and drill rig specifications; proper compatibility ensures smooth energy transfer, minimizes internal wear, simplifies maintenance, and improves overall drilling reliability.

Conclusion

BR standards in DTH hammers define more than just naming—they control how the hammer and bit connect, how air flows, and how energy transfers to the rock. Selecting the correct BR type ensures smooth operation, faster penetration, reduced wear, and consistent hole quality across different drilling conditions.

Using mismatched BR hammers and bits can lead to air leakage, lower efficiency, and premature equipment damage. By understanding BR1 and BR2 specifications, drillers and buyers can make informed decisions that improve productivity while minimizing downtime and operating costs on site.

For reliable performance and long service life, sourcing the right BR DTH hammer is just as important as proper operation. Get wholesale BR DTH hammer solutions from our Sinodrills, where proven designs, stable quality, and professional support help your drilling projects run smoothly and efficiently.