A centralizer is a key component in self-drilling anchor systems, ensuring the anchor remains properly aligned during installation. Proper alignment is critical for effective rock stabilization, as it allows uniform load distribution and enhances overall safety in construction, mining, and tunneling projects.

This blog explores the role, types, and benefits of centralizers in self-drilling anchor systems. By understanding how centralizers work, engineers and contractors can improve drilling efficiency, reduce errors, and ensure long-lasting structural stability, making them an essential element in any rock stabilization project.

What is Centralizer for Self-Drilling Anchor System?

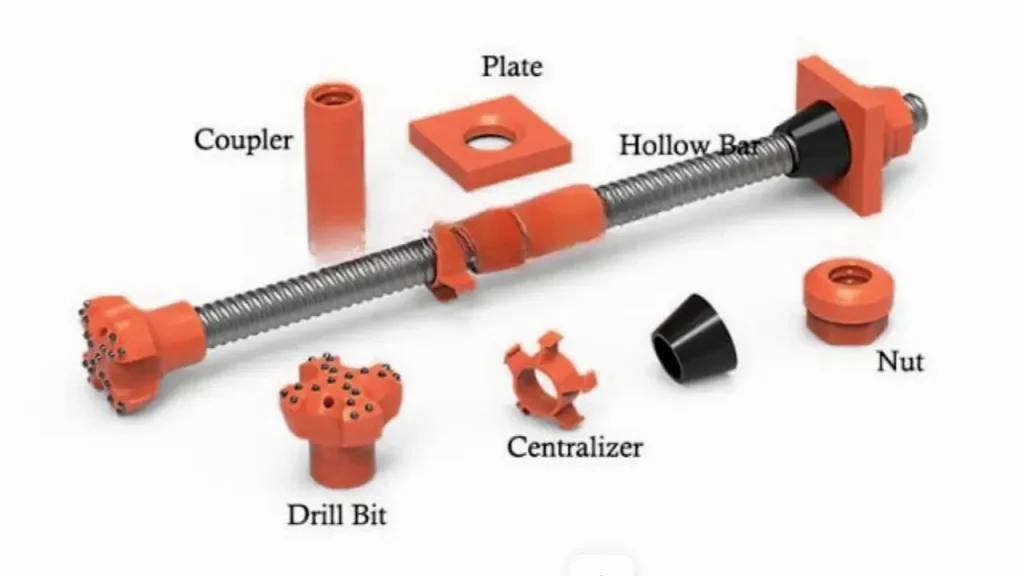

A centralizer is a device used in self-drilling anchor systems to keep the anchor rod perfectly centered within the drilled hole.

Ensuring proper alignment, it promotes uniform load distribution, prevents deviation during installation, and enhances the overall stability and effectiveness of rock stabilization projects.

How Do Centralizer for Self-Drilling Anchor System Work?

Centralizers ensure that the anchor rod remains centered in the drilled hole, optimizing load distribution and enhancing rock stabilization. Their operation involves precise positioning and support throughout the drilling and grouting process.

- Maintains Alignment: Centralizers keep the anchor rod perfectly centered, preventing deviations that could reduce load capacity and compromise stability in the rock formation. Proper alignment ensures even stress distribution along the entire anchor length.

- Supports During Drilling: They provide mechanical support while the anchor is being drilled, reducing wobbling or bending. This stabilizes the drilling process, enhances precision, and allows smoother penetration in hard or fractured rock.

- Facilitates Effective Grouting: By holding the anchor centrally, centralizers allow uniform grouting around the rod. This ensures full contact between grout and rock, improving bond strength and overall stability of the reinforced rock structure.

- Reduces Installation Errors: Centralizers minimize installation mistakes by guiding the anchor along the intended path. This increases efficiency, reduces material waste, and ensures consistent performance in large-scale rock stabilization projects.

- Enhances Structural Longevity: Properly centered anchors distribute loads evenly, preventing stress concentrations that could lead to rock fractures. This prolongs the life of the stabilization system and maintains slope or tunnel integrity over time.

Why Centralizer Necessary for a Self-Drilling Hollow Anchor System?

Centralizers are essential for self-drilling hollow anchor systems because they ensure proper alignment, uniform load distribution, and efficient grouting. Their use enhances the stability and safety of rock formations, minimizes installation errors, and extends the lifespan of anchors in construction and mining projects.

Key Reasons for Using Centralizers:

- Ensures Proper Alignment: Centralizers keep the anchor rod perfectly centered within the drilled hole. This alignment prevents deviation, ensures even stress distribution, and maximizes the anchor’s load-bearing capacity, contributing to effective and long-lasting rock stabilization.

- Improves Grouting Efficiency: By maintaining central positioning, centralizers allow grout to fill the annular space evenly. This creates full contact between the grout and rock, enhancing bonding, increasing anchor performance, and reducing the risk of weak points.

- Reduces Installation Errors: Centralizers guide the anchor along the correct path, minimizing mistakes during drilling and insertion. This reduces material waste, saves time, and ensures consistent performance across multiple anchors in large-scale stabilization projects.

- Enhances Structural Stability: Properly centered anchors distribute loads evenly across rock formations. This prevents stress concentrations, reduces the likelihood of fractures, and ensures long-term stability in tunnels, slopes, or excavation sites.

- Extends Anchor Lifespan: By maintaining alignment and improving grouting, centralizers prevent premature wear, corrosion, or failure. This ensures the self-drilling hollow anchor system performs reliably over time, supporting safe and durable rock stabilization solutions.

Where to Use Centralizer for Self Drilling Anchor System?

Centralizers are essential components for a self-drilling anchor (SDA) system, ensuring the anchor rod stays centered in the borehole. Proper placement improves grout distribution, enhances load-bearing capacity, and prevents uneven stress on surrounding rock.

Knowing where to use centralizers can significantly impact the efficiency and safety of your anchoring project.

- Near the borehole entry: Placing a centralizer close to the borehole opening stabilizes the anchor rod during insertion. This positioning prevents the rod from scraping the borehole walls, reduces deviation, and ensures smooth installation. It also helps maintain consistent alignment for subsequent grouting operations.

- Along the free length of the anchor: Centralizers spaced along the free length of the anchor keep the rod centered in the borehole. This positioning ensures uniform grout coverage, maximizes bonding with surrounding rock, and distributes stress evenly, improving the overall performance of the self-drilling anchor system.

- At the bond length section: Installing a centralizer at the bond length portion ensures proper contact between grout and rock. It prevents voids, enhances load transfer, and increases the anchor’s long-term stability. Correct placement here is crucial for achieving the designed load-bearing capacity.

- Before sharp bends or irregular sections: When the borehole has bends or uneven sections, centralizers help guide the anchor rod through safely. They minimize friction, prevent rod deformation, and maintain alignment, ensuring the anchor system performs effectively even in complex geological conditions.

How to Choose Centralizer for Self Drilling Anchor System?

Choosing the right centralizer for a self-drilling anchor (SDA) system is vital for ensuring proper borehole alignment, uniform grout distribution, and optimal load transfer. Factors like borehole diameter, rock conditions, anchor type, and installation method all influence the selection process. Selecting correctly improves safety, efficiency, and the long-term performance of your anchoring system.

- Borehole diameter compatibility: The centralizer must match the borehole size to maintain proper rod alignment. Too small or too large centralizers can cause uneven grout flow, increased friction, or rod deviation, reducing the effectiveness of the anchor and potentially compromising structural stability.

- Rock and soil conditions: Hard or abrasive rock may require more robust centralizers to resist wear, while softer formations might need flexible or adjustable types. Proper selection ensures the centralizer can withstand the geological conditions without deforming or losing centering performance during installation.

- Anchor type and diameter: Different anchor rods require specific centralizer designs for optimal fit. Choosing a centralizer that matches the rod diameter and type ensures stability, prevents excessive wear, and maintains the rod’s alignment throughout the borehole for consistent grout coverage.

- Installation method and spacing: The method of inserting the anchor affects centralizer design choice. Some require fixed or clip-on centralizers, while others need adjustable types. Correct spacing along the anchor ensures uniform support and maximum load transfer between the anchor and surrounding rock.

- Material and corrosion resistance: Centralizers made from durable, corrosion-resistant materials like stainless steel or reinforced plastics provide long-term performance. Choosing the right material ensures the centralizer withstands environmental conditions, chemical exposure, and mechanical stress without failure during the anchor’s lifespan.

Conclusion

Centralizers play a vital role in maintaining anchor alignment, improving drilling efficiency, and ensuring safe, effective rock stabilization. Their proper use enhances the performance of self-drilling anchor systems and contributes to the overall durability of slopes, tunnels, and excavation sites.

Choosing the right type of centralizer depends on rock conditions, project requirements, and anchor design. Using high-quality materials ensures long-term reliability, reduces maintenance, and provides consistent performance, making centralizers an indispensable tool in modern stabilization practices.

For premium self-drilling anchor systems and accessories, get wholesale products from our Sinodrills. We offer reliable, high-quality equipment designed for durability, precision, and efficiency, helping your rock stabilization projects succeed safely and cost-effectively.