Welcome to the ultimate guide on DTH (Down-The-Hole) drilling, a powerful and efficient method for tackling tough rock formations. This technique utilizes a pneumatic hammer positioned directly behind the drill bit, delivering rapid percussive blows while rotating to break up and pulverize rock.

In this comprehensive exploration, we’ll delve into the mechanics of DTH drilling, its key advantages over other methods, and its diverse applications across various industries, including mining, construction, and water well drilling.

Discover how this technology achieves precision, speed, and cost-effectiveness in challenging drilling environments.

What Is DTH Drilling

DTH (Down-The-Hole) drilling is a powerful and efficient method used to create boreholes in hard rock and other tough formations. At its core, DTH drilling involves a pneumatic hammer that is located directly behind the drill bit at the bottom of the drill string.

Compressed air is used to power this hammer, which rapidly strikes the drill bit, pulverizing the rock into small cuttings and dust. This direct impact mechanism ensures efficient energy transfer to the rock face, leading to faster penetration rates compared to other drilling methods in hard materials.

The compressed air not only powers the hammer but also serves a crucial role in evacuating the cuttings from the borehole. As the drill bit breaks the rock, the high-pressure air flushes the debris upwards and out of the hole, keeping the bit clean and ensuring continuous drilling progress.

This dual functionality of the compressed air makes DTH drilling particularly effective for deep hole drilling and in applications where efficient removal of cuttings is essential for maintaining drilling speed and accuracy. DTH drilling is widely employed in mining, construction, water well drilling, and the oil and gas industry due to its ability to handle challenging geological conditions.

Down the Hole Drilling Tools

The efficiency and overall success of any DTH operation rely entirely on the specialized tools used below the surface. We provide a complete range of these components, each designed to withstand extreme downhole forces and harsh geological conditions. Selecting the appropriate tool assembly for the target rock type and drilling objective is paramount to achieving the necessary penetration rates and borehole quality for the project.

We manufacture these drilling tools with precision to ensure perfect compatibility and optimal energy transfer from the drill rig to the rock face. This integrated system of components, including the hammer and the bit, works in unison to deliver the necessary percussive and rotational forces. We ensure that every piece is built to maximize operational lifespan and reduce downtime, allowing us to maintain project schedules effectively.

DTH Drill Hammer

The DTH drill hammer is the engine of the entire system, converting high-pressure air into powerful, rapid percussive blows. We supply hammers engineered for efficiency, featuring robust internal components like the piston and cylinder assembly that cycle at very high frequencies. This repeated, intense impact action is what fractures the rock effectively, making DTH the preferred method for drilling in medium to hard rock strata.

We design our hammers with straightforward maintenance in mind, ensuring field serviceability and long wear life. The hammer body also serves as the main conduit for the exhaust air, which is strategically directed to flush cuttings out of the borehole. This dual function of percussion and cleaning is essential for continuous, unobstructed drilling, and we guarantee our designs optimize both.

DTH Drill Bit

The DTH drill bit is the actual cutting tool that engages with the rock, and its design is crucial for maximizing penetration and longevity. We offer a diverse selection of bits, including convex, flat-face, and concave designs, each tailored to different rock characteristics and desired hole straightness. The buttons on the drill bit face, typically made of tungsten carbide, are wear-resistant and designed to sustain thousands of powerful impacts.

We pay close attention to the carbide grade and button placement, ensuring the optimal balance between aggressive penetration and resistance to premature wear. The bit is connected directly to the shank of the hammer, receiving the full force of the piston blow. This direct link allows us to achieve superior cutting performance and ensures that the finished borehole diameter meets the precise specifications of the project.

Drill Pipe

The drill pipe is the connecting element that performs three vital functions: it transmits rotation from the drill rig to the hammer, supplies the necessary compressed air, and provides the mechanism for applying feed force. We manufacture our drill pipes from seamless steel tubing, engineered to manage the high torsional stress and internal air pressure inherent in DTH operations.

Beyond its structural integrity, the quality of the thread connections on the drill pipe is essential for maintaining the sealed pathway required for the air supply. We guarantee the consistency of these threads to prevent pressure loss and ensure a secure connection throughout the entire length of the drill string. This commitment to detail provides the necessary stiffness and reliability for deep hole applications.

| Tool Component | Primary Function | Materials We Use | Key Performance Metric |

|---|---|---|---|

| DTH Drill Hammer | Generates high-frequency percussive force | Proprietary Alloy Steel | Blows Per Minute (BPM) |

| DTH Drill Bit | Fractures and cuts the rock face | Tungsten Carbide Inserts, Steel Body | Penetration Rate (ROP) |

| Drill Pipe | Transmits rotation, air, and feed force | Seamless Steel Tubing | Torsional Strength & Thread Life |

| Compressor (Surface) | Provides high-volume, high-pressure air | Industrial-Grade Components | Air Volume (CFM) & Pressure (PSI) |

What Are Down the Hole Hammers?

Recommended DTH Hammers

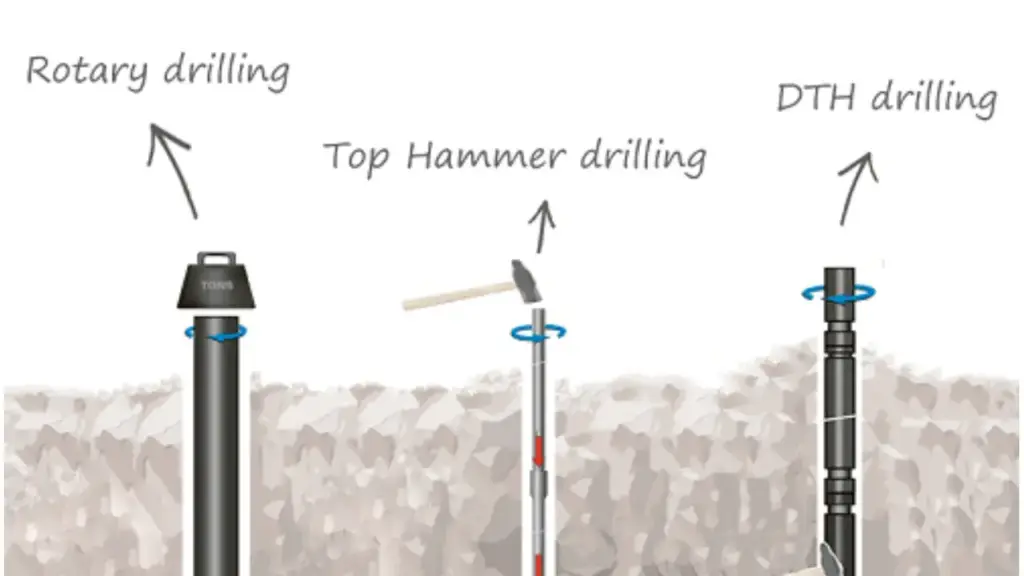

Down-the-Hole (DTH) hammers are a type of drilling tool used to create holes in rock formations. Unlike top-hammer drills, which use percussive force from the surface, a DTH hammer is located directly at the bottom of the drill string, just above the drill bit.

It works like a jackhammer, using compressed air to drive a piston that repeatedly strikes the back of the drill bit, transferring energy directly to the rock. This makes DTH hammers highly efficient for drilling deep, straight, and large-diameter holes in very hard rock, as they minimize energy loss over the length of the drill string.

- Mining and Quarrying: DTH hammers are widely used for drilling blast holes in open-pit mines and quarries to break up large rock formations for mineral and aggregate extraction.

- Construction and Civil Engineering: They are essential for a variety of tasks, including creating holes for foundations, anchors, and pilings in both urban and rural projects.

- Geotechnical and Water Well Drilling: DTH hammers are also used for drilling deep boreholes to assess ground conditions for new construction, or to create water wells and geothermal energy wells.

Where Is DTH Drilling Used

DTH drilling is a versatile and powerful technique employed across a multitude of industries due to its efficiency in penetrating hard rock formations. The direct impact mechanism and effective cuttings removal make it a preferred method for various applications requiring precise and deep boreholes.

Let’s explore some of the key areas where DTH drilling plays a crucial role.

Mining Operations

In the mining industry, DTH drilling is extensively used for drilling blast holes. These holes are strategically placed and filled with explosives to fracture the rock mass, allowing for the extraction of valuable ores and minerals. The accuracy of DTH drilling ensures precise blasting, which is critical for efficient and safe mining operations. Furthermore, DTH drilling is also employed in mineral exploration to obtain core samples for geological analysis, helping to identify and assess potential ore deposits. The ability of DTH to penetrate hard and abrasive rock makes it indispensable in both surface and underground mining environments.

Construction and Infrastructure

The construction sector relies on DTH drilling for various applications, including foundation drilling, piling, and ground consolidation. When constructing large structures or infrastructure projects like bridges and tunnels, stable foundations are paramount. DTH drilling can create deep and accurate boreholes in challenging ground conditions, which are then filled with concrete or used for installing piles to support heavy loads. Additionally, DTH drilling is used for soil nailing and other ground stabilization techniques, ensuring the safety and longevity of construction projects, especially in areas with unstable or rocky terrain.

Water Well Drilling

DTH drilling is a highly effective method for drilling water wells, particularly in regions with hard rock aquifers. Its ability to быстро penetrate dense formations allows for quicker access to groundwater resources. The clean and straight boreholes produced by DTH drilling are ideal for installing well casings and ensuring efficient water flow. Moreover, the cuttings removal mechanism helps maintain the integrity of the borehole, reducing the risk of collapse and contamination, which is crucial for providing clean and reliable water supplies to communities and agricultural operations.

Oil and Gas Exploration

While not as dominant as rotary drilling in the overall oil and gas industry, DTH drilling plays a significant role in specific applications, particularly in shallower wells or in hard rock formations encountered during exploration. Its precision and ability to drill straight holes are valuable when targeting specific geological structures.

In some cases, DTH drilling is used for initial drilling phases or for creating pilot holes before larger drilling operations commence. The efficiency of DTH in hard rock can also be advantageous in certain unconventional resource plays.

DTH Drilling Advantages

DTH drilling offers several key advantages that make it a preferred method in various applications. Its direct power transmission to the drill bit results in high penetration rates, especially in hard rock formations, leading to faster project completion times and increased productivity.

Furthermore, the efficient removal of cuttings by compressed air ensures a clean borehole and optimal drilling performance, reducing the risk of bit jamming and improving overall efficiency.

- High Penetration Rates: The direct impact of the hammer on the bit ensures efficient energy transfer, allowing for rapid drilling progress through even the toughest rock. This speed translates to quicker project turnaround and reduced operational hours.

- Excellent Hole Straightness: Due to the hammer being located directly behind the bit, DTH drilling provides superior accuracy and minimizes hole deviation compared to other methods. This is crucial for applications requiring precise borehole alignment.

- Effective Cuttings Removal: The continuous flow of compressed air efficiently flushes rock cuttings out of the borehole, preventing their accumulation and ensuring the drill bit remains clean for optimal cutting action and drilling speed.

- Versatility in Hard Rock: DTH drilling excels in hard and abrasive rock formations where other drilling techniques may struggle or experience higher wear and tear. This makes it ideal for mining, quarrying, and construction in challenging geological conditions.

DTH Drilling Applications

DTH drilling’s versatility makes it indispensable across numerous sectors, providing efficient and precise borehole creation in challenging geological conditions. Its applications range from large-scale industrial operations to essential infrastructure development, highlighting its adaptability and effectiveness.

The method’s ability to penetrate hard rock with speed and accuracy, coupled with efficient cuttings removal, ensures its continued importance in various drilling endeavors.

- Mining Operations: DTH drilling is crucial for drilling blast holes for rock fragmentation and ore extraction, ensuring precise blasting patterns and efficient resource recovery. It’s also vital for mineral exploration, providing accurate core samples for geological analysis to identify potential ore deposits in diverse mining environments.

- Construction and Infrastructure: In construction, DTH drilling is used for creating stable foundations through piling and ground consolidation in challenging terrains, supporting large structures like bridges and buildings. It also facilitates soil nailing and ground stabilization techniques, enhancing the safety and longevity of infrastructure projects in various soil conditions.

- Water Well Drilling: DTH drilling offers a rapid and effective method for accessing groundwater resources, especially in hard rock aquifers, ensuring clean and straight boreholes for efficient water extraction. The cuttings removal system maintains borehole integrity, crucial for providing reliable water supplies for communities and agriculture.

- Oil and Gas Exploration: While primarily used for shallower wells or initial drilling phases in hard rock, DTH drilling provides precision for targeting specific geological structures in oil and gas exploration. Its efficiency in tough formations can be advantageous in certain unconventional resource extraction scenarios.

DTH Drilling Compressed Air Power

DTH drilling fundamentally relies on compressed air for its operation, serving two critical functions.

Firstly, the pneumatic power drives the DTH hammer located downhole; compressed air propels an internal piston to strike the drill bit repeatedly, fracturing the rock with each impact.

Secondly, the same compressed air is channeled through the drill bit, acting as an exhaust mechanism to efficiently remove the rock cuttings and dust from the borehole, ensuring the bit remains clean and drilling progresses effectively.

- Pneumatic Hammer Power: Compressed air directly powers the hammer’s piston, delivering rapid and forceful impacts to the drill bit, which is essential for effectively breaking through hard rock formations. This direct energy transfer maximizes drilling efficiency at the bottom of the hole.

- Cuttings Removal via Air Exhaust: The compressed air, after powering the hammer, exits through the drill bit and flows upwards, carrying away the pulverized rock cuttings and dust. This continuous flushing action prevents clogging and ensures optimal drilling performance by maintaining a clean borehole.

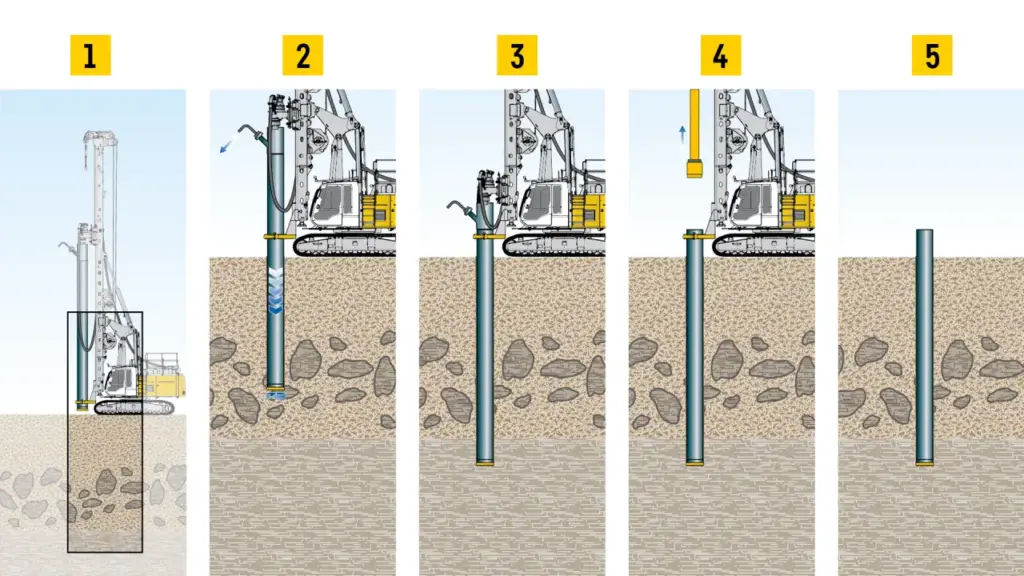

Down the Hole Drilling Method

The DTH method is a sequence of precise operational steps that lead to highly effective rock penetration. We leverage the system’s unique location of the percussive hammer—directly at the bottom of the borehole—to minimize energy loss and ensure consistent performance. Understanding the method’s cycle is key to optimizing drilling parameters and maximizing resource efficiency on site.

The entire drilling process is managed from the surface, where we control rotation, feed pressure, and the crucial air supply. This compressed air activates the hammer and simultaneously cleans the hole. We apply feed force and rotate the drill string slowly to distribute wear evenly and guide the bit, maintaining the required straightness and trajectory.

- Air Compressor and Hammer Activation Compressed air is supplied from the surface, traveling through the drill pipe to power the DTH hammer’s internal piston. This continuous airflow initiates the rapid percussive action, driving the drill bit against the rock. We carefully monitor air pressure for optimal strike force and maximum downhole efficiency.

- Controlled Rotation and Feed Pressure The drill string is rotated slowly by the top drive to ensure all gauge buttons on the bit wear evenly and the hole remains circular. Simultaneously, we apply calculated weight (feed pressure) to the bit, which helps transfer the hammer’s percussive energy effectively into the rock, boosting penetration.

- Cuttings Evacuation (Flushing) The exhaust air from the DTH hammer is immediately directed upward through the annulus (the space between the drill pipe and the borehole wall). This powerful air jet lifts the rock cuttings, or chips, out of the hole, ensuring the bit can continually engage fresh rock without obstruction, maintaining a clear path.

- Adding New Drill Pipes As the hammer drills deeper, we sequentially add new sections of drill pipe to the string. This critical process requires temporarily stopping percussion and rotation to secure the connection. We ensure reliable threading on our pipes to maintain continuous air pressure down the increasing length of the hole.

Quieter Drilling Compared with Other Methods

While DTH drilling is known for its efficiency in hard rock, it generally produces a significant amount of noise, often comparable to other percussive drilling methods like jackhammers or some types of rotary drilling.

The high-frequency impacts of the downhole hammer against the rock generate considerable sound energy that travels both through the ground and the air.

Additionally, the expulsion of high-pressure air carrying rock cuttings contributes to the overall noise level at the drilling site. Therefore, in terms of noise reduction, DTH drilling doesn’t inherently offer a quieter operation compared to many other drilling techniques.

However, the perceived loudness can be influenced by several factors, including the specific equipment used, the geology of the drilling site, and any noise mitigation measures implemented. While the fundamental process of DTH drilling is noisy, advancements in technology and operational practices can help to reduce the impact.

For instance, using mufflers on the air compressor exhaust and implementing sound barriers around the drilling area can help to dampen the noise. Ultimately, while DTH drilling is powerful, quieter alternatives might be preferred in noise-sensitive environments if drilling conditions allow for their use.

Conclusion

In conclusion, DTH drilling stands out as a powerful and efficient method, particularly excelling in challenging hard rock formations and deeper drilling applications. Its direct power transmission ensures accuracy and speed, making it a preferred choice across various industries. Understanding the nuances of DTH drilling empowers professionals to optimize their operations for enhanced productivity and cost-effectiveness.

For those seeking to leverage the advantages of DTH drilling, sourcing high-quality tools is paramount. Sinodrills emerges as a reputable manufacturer and supplier of wholesale DTH drilling tools. Their commitment to quality and performance ensures that you can acquire reliable equipment tailored to your specific drilling needs.

Investing in the right DTH drilling tools can significantly impact the success of your projects. By partnering with a trusted supplier like Sinodrills, you gain access to a comprehensive range of durable and efficient solutions, ultimately maximizing your drilling capabilities and achieving optimal results.