Welcome to the ultimate guide on geotechnical drilling! This crucial process involves investigating subsurface conditions by drilling into the earth. Through the collection and analysis of soil and rock samples, engineers gain vital insights into the ground’s composition and properties.

This information is paramount for ensuring the safety and stability of construction projects. Geotechnical drilling helps identify potential hazards and informs the design of robust foundations, ultimately mitigating risks and ensuring long-lasting structures. Join us as we delve deeper into this essential practice!

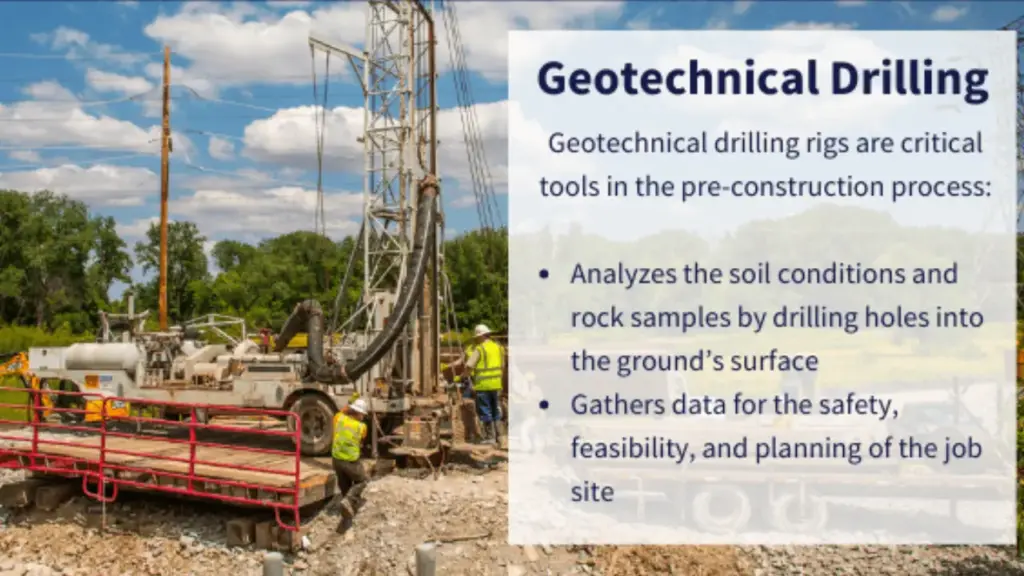

What is Geotechnical Drilling

Geotechnical drilling is a crucial process in civil engineering and construction. It involves drilling boreholes into the ground to investigate subsurface conditions. The primary purpose is to collect soil and rock samples, which are then analyzed to determine their physical and mechanical properties. This information is vital for assessing the suitability of a site for construction, designing stable foundations, and identifying potential geological hazards.

The data obtained from geotechnical drilling informs critical decisions throughout a project lifecycle. It helps engineers understand soil composition, bearing capacity, groundwater levels, and the presence of any contaminants. This knowledge allows for the development of appropriate foundation designs for buildings, bridges, roads, and other infrastructure, ensuring their long-term stability and safety.

Importance of Geotechnical Drilling

Geotechnical drilling plays a vital role in ensuring the success and safety of numerous projects by providing essential subsurface information. This detailed understanding of soil and rock conditions allows for informed decision-making throughout the project lifecycle. Key aspects of its importance include:

- Risk Mitigation: Identifying potential geological hazards, unstable soil layers, and groundwater issues early in the project, preventing costly delays and failures.

- Cost Optimization: Providing accurate data for efficient design and material selection, reducing unnecessary expenses and ensuring the most suitable construction methods.

- Safety Enhancement: Ensuring the stability and longevity of structures by providing the necessary information for safe foundation design and construction practices.

- Environmental Protection: Facilitating the assessment and remediation of contaminated sites, protecting soil and groundwater resources.

- Regulatory Compliance: Meeting building codes and environmental regulations that often require thorough geotechnical investigations.

- Informed Decision-Making: Supplying engineers and stakeholders with the crucial data needed to make sound judgments regarding site suitability, design parameters, and construction techniques.

How is Geotechnical Drilling Conducted?

Geotechnical drilling involves a systematic process to investigate subsurface conditions. It typically begins with site investigation and planning, followed by the actual drilling and sampling, and concludes with laboratory testing and reporting of the findings.

Site Investigation and Planning

Before drilling commences, a thorough site investigation is conducted. This involves reviewing existing geological data, topographic maps, and historical records to understand the general subsurface conditions.

A drilling plan is then developed, outlining the number, location, and depth of boreholes based on the project requirements and the initial site assessment. Access for drilling equipment and potential site constraints are also carefully considered during this stage.

Drilling and Sampling

The core of geotechnical drilling involves advancing boreholes into the ground using various drilling techniques, as previously discussed (e.g., DPT, auger, rotary). As the drilling progresses, soil and rock samples are collected at predetermined intervals or when changes in subsurface materials are observed.

The sampling method depends on the soil type and the required level of sample disturbance. Common methods include split-spoon sampling for disturbed samples and Shelby tube sampling or coring for relatively undisturbed samples. Field observations, such as soil color, texture, and consistency, are also meticulously recorded during the drilling process.

Laboratory Testing and Reporting

Once the samples are retrieved, they are transported to a laboratory for detailed testing. These tests determine crucial soil properties such as grain size distribution, Atterberg limits, moisture content, shear strength, and compressibility. For rock samples, tests may include unconfined compressive strength and permeability.

The results of these laboratory tests, along with the field observations and drilling logs, are compiled into a comprehensive geotechnical report. This report provides engineers with the necessary data and interpretations to make informed decisions regarding design and construction.

Types of Geotechnical Drilling

Geotechnical drilling employs various methods to investigate subsurface conditions. Each technique has specific applications and limitations based on soil type and project requirements. Here’s an overview of common geotechnical drilling types.

Direct Push Technology (DPT) Geotechnical Drilling

DPT is a cost-effective and straightforward method that uses force or percussion to push small drill rods into the ground for shallow investigations. While efficient for softer soils, DPT can encounter refusal in dense or rocky materials, limiting its depth capabilities.

Hollow Stem Auger Geotechnical Drilling

This technique utilizes torque and downward force to advance screw-like drill bits through formations like sand, clay, and silt. It’s a relatively inexpensive option, but similar to DPT, it’s prone to refusal in rocky or very dense subsurface conditions, restricting its use in such environments.

Sonic Geotechnical Drilling

Sonic drilling employs high-frequency vibrations to resonate drill pipes, allowing for continuous core sampling with minimal refusal. This method is advantageous for detailed geological analysis but requires specialized equipment and trained personnel, often resulting in higher project costs.

Rotary Geotechnical Drilling

Rotary drilling encompasses several related techniques that use a rotating bit attached to a drill pipe for deeper penetration and wider boreholes. Its versatility allows adaptation to various geological conditions, making it a valuable method for diverse project sites.

Wireline and Diamond Coring Geotechnical Drilling

These methods utilize a rotating core barrel bit, often with diamond inserts, to efficiently extract samples from tough formations. They offer a fast way to collect core samples, although the maximum sample diameter is limited to 3.27 inches, which might necessitate alternative methods for larger sample requirements.

What Equipment Is Used for Geotechnical Drilling

Geotechnical drilling relies on a variety of specialized equipment to access and sample subsurface materials. The specific equipment used depends on the drilling method, the depth of investigation, and the ground conditions encountered. Common pieces of equipment include:

- Drill Rigs: These are the primary machines used to advance boreholes into the ground. They come in various types and sizes, including truck-mounted, track-mounted, and portable rigs, each suited for different site access and drilling requirements.

- Drill Rods and Augers: Drill rods are connected to form the drill string and transmit power to the cutting tool. Augers are helical tools used in softer soils to bore holes and bring cuttings to the surface. Different types of augers are available for various soil conditions.

In addition to the main drilling machinery, several other essential tools and accessories are utilized during geotechnical drilling operations. These ensure efficient and accurate sample collection and borehole stability. Key supporting equipment includes:

- Sampling Tools: These include split-spoon samplers for Standard Penetration Tests (SPT), Shelby tubes for collecting undisturbed soil samples, and core barrels with various bits (e.g., rock coring bits) to retrieve rock cores.

- Drilling Fluids and Additives: These are used in rotary drilling to stabilize the borehole, cool the drill bit, and remove cuttings. Common fluids include water, bentonite slurry, and polymers.

- Casing: Steel or PVC pipes inserted into the borehole to prevent collapse, especially in unstable soils, and to isolate different subsurface zones.

- Pumps and Hoses: Used to circulate drilling fluids and remove cuttings from the borehole.

- Surveying Equipment: Essential for accurately locating and marking borehole locations and determining drilling depths.

What Projects Need Geotechnical Drilling?

Geotechnical drilling is essential for a wide range of construction and infrastructure projects. It provides critical subsurface information needed for safe and stable development. These projects commonly include:

- Construction of buildings, bridges, and other structures to determine foundation requirements and soil bearing capacity.

- Road and railway construction to assess subgrade stability and identify suitable materials.

- Dam and levee construction to evaluate soil strength and permeability for structural integrity.

- Tunneling projects to understand ground conditions and potential excavation challenges.

- Environmental investigations to identify soil and groundwater contamination.

- Landslide and slope stability analyses to assess potential risks and design mitigation measures.

- Dredging and marine construction to characterize seabed sediments and stability.

Geotechnical Drilling Applications

Geotechnical drilling serves a multitude of critical applications in various sectors, primarily focusing on understanding and characterizing subsurface conditions. The insights gained are fundamental for informed decision-making and ensuring the safety and stability of numerous projects.

Key applications of the geotechnical drilling include:

- Foundation Design: Determining soil bearing capacity, settlement characteristics, and the depth to suitable bearing layers for buildings, bridges, and other structures.

- Slope Stability Analysis: Investigating soil and rock strength parameters, groundwater conditions, and potential failure surfaces to assess and mitigate landslide risks.

- Tunneling and Underground Construction: Characterizing rock mass properties, identifying potential hazards like weak zones or water inflow, and optimizing excavation methods.

- Dam and Levee Engineering: Evaluating the permeability and strength of embankment materials and the underlying foundation to ensure structural integrity and prevent seepage.

- Environmental Investigations: Collecting soil and groundwater samples to identify and delineate contamination, assess its extent, and plan remediation strategies.

- Resource Exploration: Obtaining core samples of soil and rock to evaluate the presence and quality of mineral deposits or other natural resources.

- Ground Improvement Techniques: Assessing the effectiveness of methods like soil compaction, grouting, or soil mixing by analyzing pre- and post-treatment soil properties.

- Instrumentation Installation: Creating boreholes for the installation of monitoring wells, piezometers, inclinometers, and other instruments to track groundwater levels, pore water pressures, and ground movements over time.

Who is Responsible for Geotechnical Drilling?

The responsibility for geotechnical drilling typically rests with a team of professionals working collaboratively. The primary party responsible for overseeing and managing the entire process is usually a geotechnical engineer or an engineering geologist.

They are responsible for planning the investigation, determining the scope of work (number and depth of boreholes), selecting appropriate drilling methods, and supervising the field operations to ensure the drilling meets the project’s requirements. They also interpret the collected data and prepare the final geotechnical report with recommendations for the project.

The actual drilling work is carried out by geotechnical drillers who are skilled in operating specialized drilling equipment and following the engineer’s instructions. They are responsible for the safe and efficient execution of the drilling plan, collecting samples, and often making initial field observations. Effective communication and coordination between the geotechnical engineer and the drilling team are crucial for obtaining accurate and reliable subsurface data. Depending on the project size and complexity, other personnel like field technicians and laboratory staff may also be involved in the process.

Conclusion

Geotechnical drilling is a vital process for understanding subsurface conditions, ensuring safer and more stable construction. This ultimate guide likely covers various drilling techniques, their applications, and the importance of accurate soil and rock analysis. By providing crucial data, geotechnical drilling helps prevent costly structural issues and ensures project success.

For those involved in geotechnical investigations and construction, sourcing reliable drilling tools is paramount. Sinodrills offers a comprehensive range of wholesale geotechnical drilling tools. Their products are designed for efficiency and durability, meeting the demands of diverse drilling projects.

Partnering with a reputable supplier like Sinodrills ensures access to geotechnical drilling tools that contribute to accurate and effective geotechnical drilling operations. Exploring their wholesale options can provide cost-effective solutions for your project needs.