In the industry of drilling technology, hybrid drill bits represent a significant leap forward. These innovative tools are designed to overcome the limitations of conventional bits by integrating multiple cutting structures into a single design. This fusion of technologies allows them to deliver superior performance and efficiency in a wide range of challenging drilling applications.

This comprehensive guide will explore the unique characteristics of hybrid drill bits, their advantages over traditional bits, and the various types available. We’ll delve into the science behind their design, helping you understand why they are becoming the go-to choice for complex drilling projects where precision, speed, and durability are paramount.

What is a Hybrid Drill Bit?

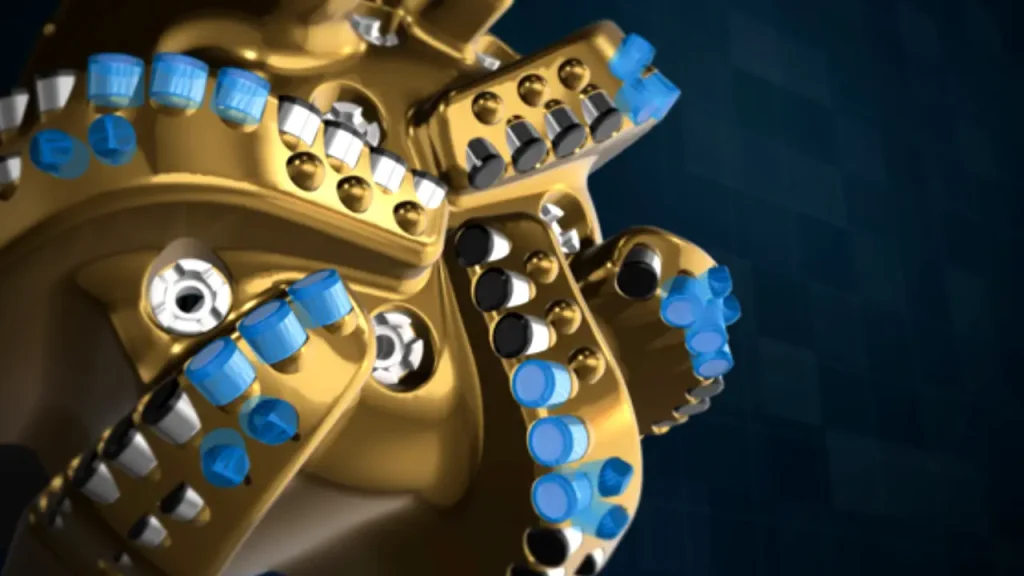

A hybrid drill bit is an advanced tool that combines two or more different cutting technologies into a single bit to optimize performance in complex and varied geological formations. Unlike a conventional roller cone or PDC (Polycrystalline Diamond Compact) bit that relies on a single rock-breaking mechanism (crushing or shearing), a hybrid bit utilizes a dual cutting approach.

For example, it might incorporate the crushing and impact strength of roller cones with the continuous shearing action of PDC cutters. This unique design allows the bit to adapt to changing rock types, from soft shales to hard, abrasive sandstones, without the need for a costly bit trip. The result is a more efficient, durable, and stable drilling operation, leading to faster penetration rates and reduced wear on downhole equipment.

How to Manufacture Hybrid Drill Bits?

Crafting hybrid drill bits is a complex process that combines sophisticated engineering and advanced materials. It involves several key stages, each crucial to creating a tool capable of superior drilling performance.

Step 1: Design and Modeling

The process begins with the intricate design of the bit. Engineers use advanced computer-aided design (CAD) software to model the bit’s geometry, including the placement of both PDC cutters and roller cones. This stage focuses on optimizing the layout to ensure maximum efficiency, stability, and durability in various drilling environments.

After the initial design is complete, engineers run simulations to test the bit’s performance under different conditions. They analyze how the bit will interact with various rock formations, predict wear patterns, and make adjustments. This virtual testing ensures the final product will meet the demanding performance requirements of real-world drilling operations.

Step 2: Manufacturing the Body

The next step is to manufacture the bit’s main body, or matrix. This is typically done through a casting or sintering process where a steel or tungsten carbide powder is formed into the desired shape. The body is designed with pockets and slots precisely where the different cutting elements will be placed later in the process.

This manufacturing phase is critical for the structural integrity of the final bit. The chosen material must be strong enough to withstand the immense forces encountered during drilling while also being able to hold the cutting elements securely in place. Precision is key to ensure all components fit together perfectly.

Step 3: Integrating Cutting Elements

With the bit body complete, the various cutting elements are then integrated. This involves brazing or press-fitting the PDC cutters into their pre-designed pockets and mounting the roller cones onto their bearings within the bit’s frame. Each component is carefully positioned according to the initial design.

The final assembly phase is where the hybrid nature of the bit comes to life. The combination of different cutting structures—each serving a specific function—is carefully balanced to ensure the bit can effectively break rock using multiple mechanisms, whether by shearing, crushing, or a combination of both.

Step 4: Final Machining and Finishing

Once the cutting elements are integrated, the bit undergoes a series of final machining and finishing processes. This includes precision grinding to ensure the bit’s overall shape and dimensions are accurate, as well as milling and polishing to refine the fluid channels, also known as junk slots. These channels are crucial for effectively clearing rock cuttings.

Additionally, this step involves the application of hardfacing materials on wear-prone surfaces. This extra layer of protection, often a tungsten carbide composite, significantly enhances the bit’s erosion resistance and longevity, especially in abrasive drilling environments.

Step 5: Quality Control and Inspection

The final stage is a rigorous quality control and inspection process. Each hybrid drill bit is meticulously checked for dimensional accuracy, proper placement of all cutting elements, and overall structural integrity. The brazing joints and bearing assemblies are thoroughly inspected to ensure they meet stringent quality standards.

This final check guarantees that every bit leaving the factory is free from defects and ready for the extreme demands of drilling. It includes visual inspections, as well as more advanced tests, to confirm the bit’s design and manufacturing quality are up to the task of delivering reliable and high-performance results in the field.

Types of Hybrid Drill Bits

Hybrid drill bits come in several configurations, each engineered to perform optimally in specific drilling conditions. Their design variations allow them to tackle everything from soft, sticky formations to extremely hard, interbedded rock.

Matrix Body Hybrid Bits

Matrix body hybrid bits are made from a tungsten carbide material that is infiltrated with a binder, creating a very hard, erosion-resistant body. This type of bit is ideal for drilling in highly abrasive and hard rock formations. The matrix material’s durability allows for a more aggressive cutter layout and increased blade count, which improves ROP and extends the bit’s life in challenging environments.

Steel Body Hybrid Bits

Steel body hybrid bits are machined from a high-grade steel alloy. This construction offers superior toughness and strength, making them well-suited for drilling in soft to medium-hard rock formations where impact and shock loads are a concern. The steel body allows for more complex hydraulic designs and repairability, providing a cost-effective option for certain drilling applications.

Bi-Center Hybrid Bits

Bi-center hybrid bits are a specialized type designed for drilling an oversized hole while using a standard-sized drill string. They feature two distinct cutting sections—a pilot section and a reamer section—that are offset from the bit’s center. This unique design allows the bit to pass through tight wellbore restrictions, such as casing, while still creating a larger-diameter hole below.

Fixed Cutter/Roller Cone Hybrid Bits

This is the most common type of hybrid drill bit. It combines the shearing action of fixed cutters, typically PDC cutters, with the crushing and gouging action of roller cones. This dual-action design allows the bit to efficiently drill through varying rock types, from soft shales to hard, brittle sandstones, without the need to switch bits. The fixed cutters handle the soft sections, while the roller cones break up the harder rock.

Why Choose Hybrid Drill Bits?

Choosing hybrid drill bits offers significant advantages for modern drilling operations, making them a preferred solution for complex projects. Their design, which merges multiple cutting technologies, directly addresses some of the biggest challenges faced in the field. This results in superior performance that translates into tangible benefits for efficiency and cost-effectiveness.

- Improved Drilling Efficiency: Hybrid bits can handle a wider range of rock formations in a single run. This versatility eliminates the need for frequent bit changes, drastically reducing non-productive time and accelerating the overall drilling process.

- Extended Bit Life and Durability: By combining the strengths of different cutting structures, hybrid bits distribute the work and wear more evenly. This reduces stress on individual components, leading to a longer lifespan and less risk of premature bit failure, even in abrasive conditions.

- Enhanced Drilling Stability: The unique design of hybrid bits helps to minimize vibrations and torque fluctuations. This enhanced stability leads to a smoother drilling operation, protecting downhole equipment from excessive wear and reducing the risk of costly damage.

Conclusion

In conclusion, hybrid drill bits stand out as a revolutionary advancement in drilling technology, offering a perfect blend of efficiency, durability, and versatility. By combining the strengths of different bit types, they provide a single solution for complex drilling challenges, reducing the need for multiple runs and saving valuable time and resources. Their ability to adapt to varying rock formations and drilling conditions makes them an indispensable tool for modern operations.

The adoption of hybrid drill bits signifies a move towards smarter, more sustainable drilling practices. Their enhanced performance not only boosts productivity but also contributes to lower operational costs and a reduced environmental footprint. As the industry continues to push the boundaries of what’s possible, these bits will undoubtedly play a crucial role in shaping the future of drilling.

For all your drilling needs, consider the innovative solutions offered by Sinodrills. Our extensive selection of wholesale hybrid drill bits provides the perfect combination of quality and value, ensuring you have the right tools to tackle any project with confidence. Partner with us to experience the next generation of drilling performance.