Rotary drilling stands as a cornerstone of modern well construction, offering a versatile and efficient approach to accessing subsurface resources. This comprehensive guide delves into the intricacies of rotary drilling, exploring its principles, techniques, and applications. Whether you’re a seasoned professional or new to the field, understanding rotary drilling is essential for successful well development across diverse geological landscapes.

From the fundamental mechanics of rotating a drill bit to the sophisticated management of drilling fluids and cuttings, this guide illuminates the key aspects of rotary drilling. We will explore the various types of rotary drilling methods, the essential equipment involved, and the factors that influence its effectiveness. Join us as we unravel the ultimate guide to rotary drilling.

What Is Rotary Drilling

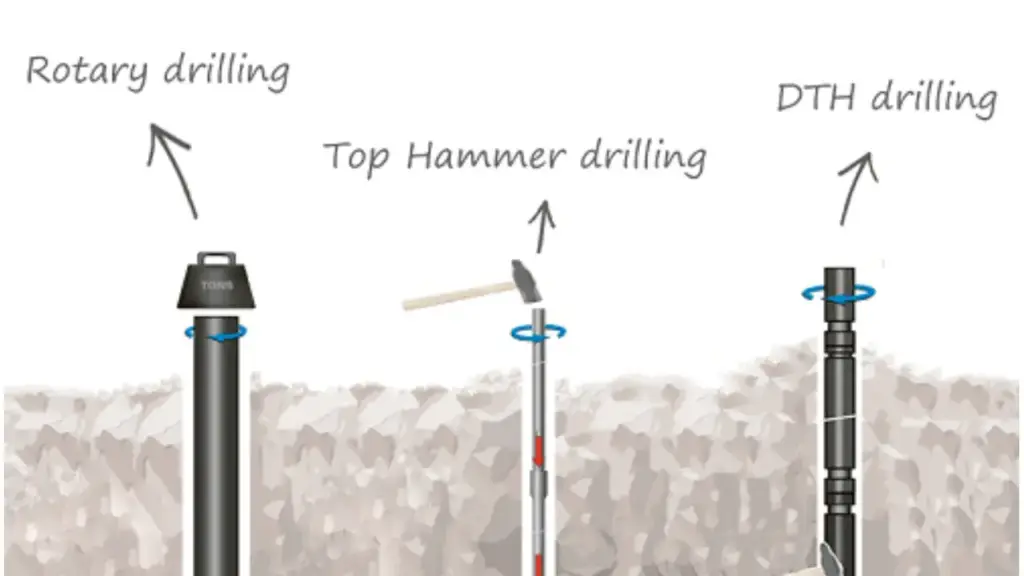

Rotary drilling is a widely used drilling method for creating boreholes in the earth by employing a rotating drill bit attached to a drill string. As the bit turns and pressure is applied, it cuts or crushes through subsurface materials, including soil and rock.

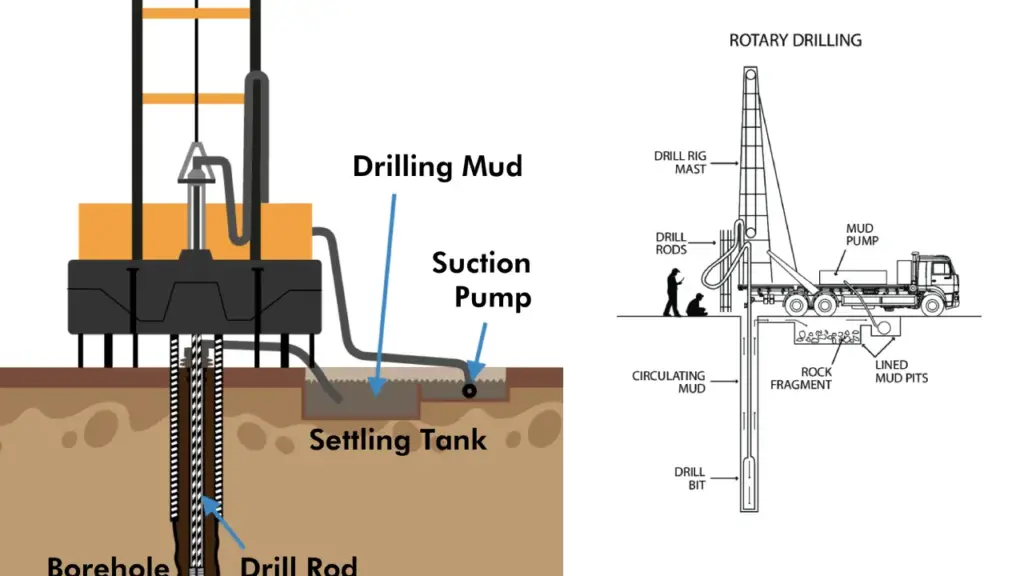

A drilling fluid, typically mud or air, is continuously circulated down the drill string to lubricate the bit, carry the generated cuttings (drilled material) back to the surface, and help stabilize the borehole walls. This technique is versatile and can be adapted for various applications, including water well drilling, oil and gas exploration, and geotechnical investigations, accommodating a wide range of geological formations and desired drilling depths.

What is Mud Rotary Drilling

Mud rotary drilling is a technique using a rotating drill bit with drilling fluid (mud) pumped down the drill pipe. The mud lubricates the bit, stabilizes the borehole walls, and carries rock cuttings to the surface. This method is effective in various soil conditions, especially unconsolidated formations like sand and gravel, and is often chosen for drilling deeper and larger diameter wells.

How Rotary Drilling Works

Rotary drilling operates by rotating a drill bit under applied weight to bore into the earth. A drill string, composed of drill pipes, transmits rotational power from the surface to the bit.

Drilling fluid, typically mud, is pumped down the drill string, exits through nozzles in the bit to cool and lubricate it, and carries the generated cuttings up the annulus (space between the drill string and the borehole) to the surface. This continuous circulation of drilling fluid is crucial for efficient drilling and maintaining borehole stability.

- Rotation and Downforce: The drill rig’s rotary table or top drive imparts rotational motion to the drill string, causing the bit to grind or cut through the subsurface. Simultaneously, weight is applied to the drill string, forcing the bit into the formation to facilitate the drilling process and achieve the desired penetration rate.

- Drilling Fluid Circulation: The constant circulation of drilling mud serves multiple vital functions. It cools the drill bit, preventing overheating and extending its lifespan. The fluid also lifts and suspends the drilled cuttings, transporting them away from the bit and up to the surface for removal, ensuring efficient drilling progress.

- Borehole Stabilization: The hydrostatic pressure exerted by the column of drilling fluid in the borehole helps to stabilize the walls, preventing collapse, especially in unconsolidated formations. This allows for the creation and maintenance of a stable and open borehole for well construction or resource extraction.

Rotary Drilling System Components

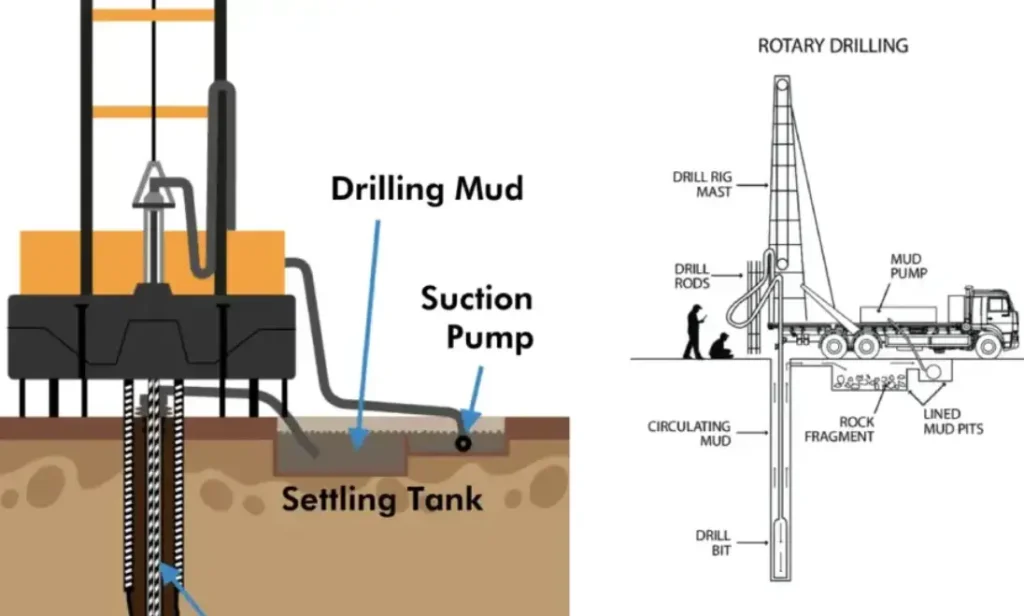

While the concept of rotary drilling is simple—using a sharp, spinning drill bit to delve into rock—the actual mechanics of modern rigs are quite complicated. A basic rotary drilling system consists of four main groups of components:

- Prime Movers (Power System): These provide the energy for the entire rig, historically steam, then diesel/gas engines, and now often natural gas generators.

- Hoisting Equipment: Tools like the derrick (the rig’s most visible part), cables, and pulleys are used to raise and lower the heavy drill string into and out of the well.

- Rotating Equipment: This system transfers power from the prime mover to the drill bit, including the swivel, drill pipe, drill collars, and the drill bit itself. Modern rigs often use a top drive instead of a rotary table and kelly.

- Circulating System: This crucial system pumps drilling fluid (mud) downhole to cool and lubricate the bit, remove cuttings, and stabilize the wellbore. It includes pumps, tanks, and plumbing.

General Rotary Drilling Methods

Recommended Drill Bits for Rotary Drilling

Rotary drilling is a fundamental method for creating boreholes in the earth, extensively used for geoformation and rock. It involves rotating a drill bit, typically under significant downward pressure, to cut or crush the subsurface material. This versatile technique is adapted for various geological conditions and applications, from soft soils to hard rock formations.

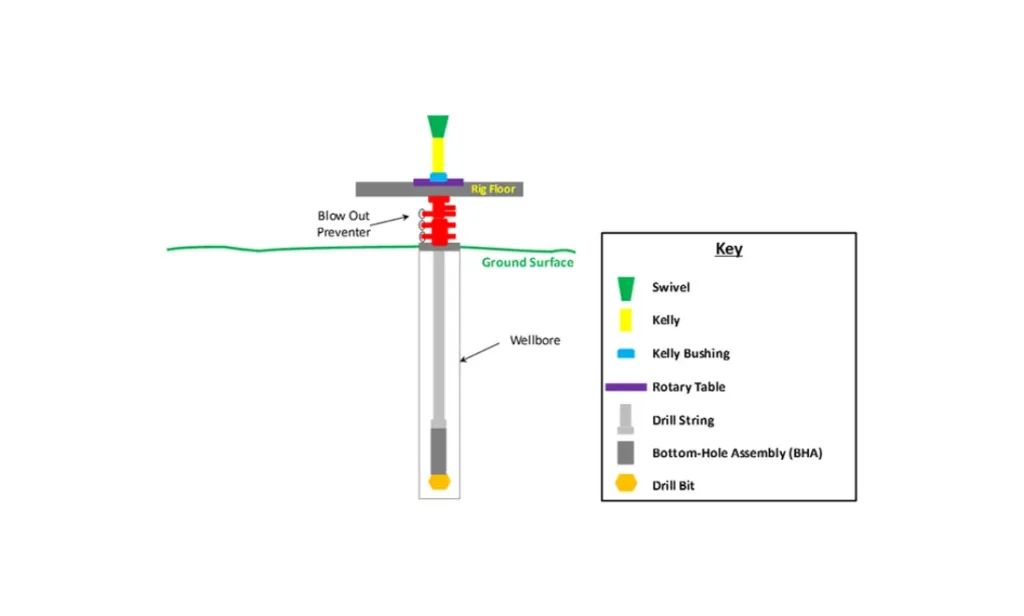

Key methods within general rotary drilling include:

- Direct Rotary (Mud Rotary): Utilizes drilling fluid (mud) to cool the bit, stabilize the borehole, and transport cuttings to the surface. Ideal for softer sediments and unstable ground, but also used for coring bedrock.

- Air Rotary: Employs compressed air to power the drill and remove cuttings. Highly effective in stable, harder rock formations where fluids might be less desirable.

- Rotary Percussive (Down-the-Hole Hammer/Top Hammer): Combines rotation with a percussive (hammering) action, delivering high impact energy to the bit for increased penetration rates in very hard rock.

- Reverse Circulation (RC): A variation of air rotary where cuttings are returned through an inner tube of dual-wall drill rods, providing cleaner and more representative samples, often favored in mineral exploration.

- Dual Rotary: Uses both an upper and lower drive system, excelling in challenging unconsolidated overburden like gravel, cobbles, and boulders.

- Sonic Drilling: Employs high-frequency mechanical vibration in addition to rotation, allowing for continuous core samples in both soft and hard formations.

What is a Rotary Drill Used For

A rotary drill is a versatile power tool primarily used for creating cylindrical holes in various materials through a rotational cutting action. Its key function involves a motor that spins a chuck, which securely holds a drill bit.

The user applies controlled pressure to the drill, forcing the rotating bit to bore into the workpiece. Many rotary drills also feature adjustable speeds and reverse functionality, enhancing their utility for different tasks and materials.

- Drilling Pilot Holes: Rotary drills are essential for creating smaller, precisely located pilot holes before using larger drill bits. This ensures accuracy and prevents the larger bit from wandering, especially in materials like wood and metal, contributing to cleaner and more controlled drilling.

- Driving Screws: Equipped with the appropriate screwdriver bit, a rotary drill can function as a power screwdriver. The adjustable speed and torque settings allow for efficient and consistent screw driving, making tasks like furniture assembly or deck building much faster and easier than manual methods.

- Creating Larger Holes with Accessories: Rotary drills can be used with various attachments like hole saws to cut larger diameter holes in wood, drywall, and even some metals. This expands their functionality beyond standard drilling for tasks such as installing light fixtures or running cables through walls.

How to Use a Rotary Drill

Operating a rotary drill effectively and safely requires understanding its components and following a systematic approach. Before commencing any drilling, ensure you have selected the appropriate drill bit for the material you intend to work with and that it is securely fastened in the drill chuck.

Always wear safety glasses to protect your eyes from flying debris and consider using gloves for better grip and vibration dampening. Familiarize yourself with the drill’s speed settings and clutch (if applicable) to match the requirements of your task and material.

Step 1: Preparing for Drilling

Before you begin drilling, securely clamp or otherwise stabilize the workpiece to prevent it from moving during the operation. This ensures accuracy and enhances safety. Mark the precise location where you intend to drill with a pencil or punch to guide the drill bit. For hard or smooth surfaces, creating a small indentation with a center punch can help prevent the drill bit from slipping as you start drilling.

Step 2: Starting the Drilling Process

Position the tip of the drill bit directly over your marked spot, holding the drill firmly with both hands. Begin drilling at a slow speed to allow the bit to establish a starting point without wandering. Apply steady, even pressure to the drill, allowing the bit to do the work. Avoid forcing the drill, as this can damage the bit or the motor and potentially be unsafe.

Step 3: Maintaining Consistent Drilling

Once the drill bit has engaged the material, maintain a consistent speed and pressure. If you encounter resistance, do not increase the pressure excessively; instead, try reducing the drilling speed slightly. For deeper holes, periodically withdraw the drill bit to clear away debris (cuttings) from the hole. This helps to prevent the bit from binding and ensures more efficient drilling.

Step 4: Completing the Drilling

As the drill bit nears the completion of the hole, ease up on the pressure to create a clean exit and prevent splintering or damage to the backside of the material. Once the bit has fully passed through, slowly withdraw the drill while it is still rotating to clear any remaining debris. Turn off the drill and allow the bit to come to a complete stop before setting it down.

Rotary Drill vs Hammer Drill

While both rotary drills and hammer drills create holes, their mechanisms and ideal applications differ significantly. A standard rotary drill primarily uses rotational force to bore through materials like wood, plastic, and metal. In contrast, a hammer drill adds a percussive hammering action to the rotation, making it more effective for drilling into masonry materials like brick, block, and softer concrete.

- Rotary Drill for General Use: Ideal for drilling clean holes in wood, metal, and plastics, rotary drills offer precision and control. They are also commonly used for driving screws with appropriate attachments, making them a versatile tool for general construction and DIY tasks where impact is not required.

- Hammer Drill for Masonry: The added hammering action allows hammer drills to chip away at brittle materials like brick and concrete as they rotate. This makes them suitable for tasks such as drilling anchor holes or creating openings in masonry walls, though they may be less efficient for harder concrete.

- Mechanism and Intensity: Rotary drills rely solely on the cutting action of the rotating bit, while hammer drills incorporate a clutch mechanism that delivers rapid, short bursts of impact. Rotary hammers, a more powerful category, use a piston-driven pneumatic mechanism for much stronger hammering, excelling in tougher concrete and masonry.

Conclusion

Rotary drilling stands as a versatile and efficient method for accessing subsurface resources, utilizing a rotating drill bit and circulating fluids to create boreholes across diverse geological formations. Its adaptability to varying depths and soil types makes it a cornerstone of modern well drilling and other drilling applications. Understanding the principles and components of rotary drilling is crucial for anyone involved in these industries.

For those seeking reliable and high-performance equipment, our factory offers a wide selection of wholesale rotary drilling tools. We provide the essential components needed for successful rotary drilling operations, ensuring durability and efficiency in every project. Contact us today to explore our range of quality drilling solutions.

Ultimately, the effectiveness of rotary drilling lies in its ability to navigate a wide range of subsurface conditions. Coupled with the right tools and expertise, it remains a fundamental technique for accessing valuable resources beneath the Earth’s surface. Consider our wholesale options for your rotary drilling tool needs.