Choosing the right drilling stabilizer is crucial for efficient and safe drilling operations. Straight blade and spiral stabilizers are two commonly used types, each offering unique advantages. Understanding their differences in design, function, and application helps drillers select the most suitable option for specific wellbore conditions and project requirements.

Straight blade stabilizers provide reliable wellbore stability and are ideal for vertical or simple directional drilling. Spiral stabilizers, with their twisted blade design, reduce vibration, improve hole cleaning, and offer enhanced directional control. This guide explores the distinctions between these stabilizers to help you make informed decisions for optimized drilling performance.

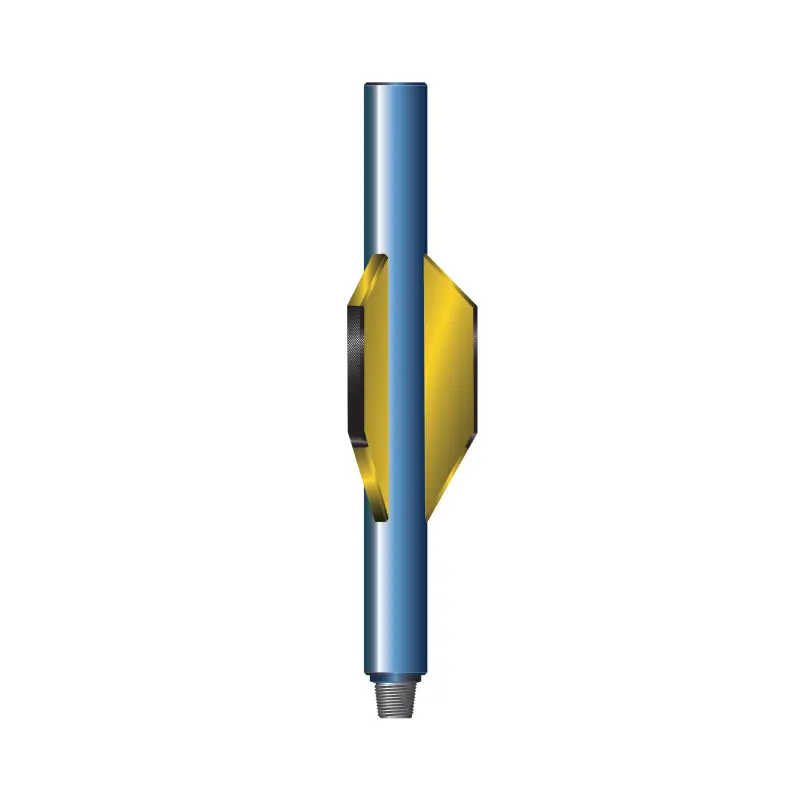

What is a Straight Blade Stabilizer?

A straight blade stabilizer is a downhole drilling tool designed to maintain wellbore stability, reduce vibration, and improve directional control. With blades aligned parallel to the drill string, it ensures smooth drilling, minimizes tool wear, and provides reliable performance in oil, gas, mining, and geothermal applications.

- Maintains Wellbore Stability: Straight blade stabilizers keep the drill string centered in the borehole, reducing lateral movement and preventing deviations. This ensures a straighter well path, minimizes the risk of doglegs, and improves overall drilling efficiency, enhancing the lifespan of drilling tools.

- Reduces Vibration: By stabilizing the drill string, these stabilizers absorb shock and dampen vibrations during drilling. This reduces wear on drill bits and collars, protects the drilling assembly, and provides smoother operation, especially in hard or abrasive formations.

- Enhances Directional Control: The straight blade design provides consistent borehole contact, allowing better control over the drill string. This ensures accurate directional drilling, maintains planned well trajectories, and supports efficient and predictable drilling performance in various formations.

- Durable and Reliable Performance: Machined from high-strength alloy steel, straight blade stabilizers are designed to withstand extreme downhole conditions. Their robust construction ensures long-lasting performance, reduces maintenance frequency, and delivers reliable results in demanding drilling environments.

What is a Spiral Blade Stabilizer?

Spiral blade stabilizers are downhole drilling tools designed to maintain wellbore stability and improve drilling efficiency. Their twisted blade design reduces vibration, enhances hole cleaning, and provides better directional control. Spiral stabilizers are widely used in oil, gas, mining, and geothermal drilling projects to ensure precise, reliable drilling performance.

- Spiral Blade Design: Spiral blades are twisted around the stabilizer body, allowing smoother contact with the borehole wall. This design reduces torsional vibration, improves drilling accuracy, and facilitates better debris removal, ensuring consistent directional control and extending the life of drill bits and other downhole tools.

- Enhanced Wellbore Stability: By maintaining constant contact with the borehole wall, spiral stabilizers prevent deviation, minimize doglegs, and stabilize the drill string. This improves overall wellbore quality, reduces tool wear, and ensures safer, more efficient drilling operations in challenging formations.

- Vibration Reduction: The spiral design absorbs and dissipates vibrations along the drill string. Reduced vibration lowers stress on the drill assembly, minimizes equipment damage, and enhances operational safety while maintaining smoother, more controlled drilling performance.

- Versatile Applications: Spiral blade stabilizers are suitable for vertical, directional, and horizontal drilling in oil, gas, geothermal, and mining operations. Their design provides consistent performance across different formation types, optimizing efficiency and extending tool life in demanding downhole environments.

Straight Blade Stabilizer vs Spiral

Straight blade and spiral stabilizers are widely used downhole tools that improve wellbore stability and drilling efficiency. Understanding their differences in design, performance, and application helps drillers choose the optimal stabilizer for specific drilling conditions and project requirements.

1. Blade Design

Straight blade stabilizers feature uniform, parallel blades attached to the body, providing consistent wellbore contact. This simple design ensures durability and predictable performance, especially in vertical or mildly deviated wells. It is easier to manufacture and maintain, offering cost-effective reliability.

Spiral stabilizers have twisted blades that wrap around the stabilizer body. This design reduces vibration, improves debris removal, and provides smoother drilling. The spiral arrangement enhances directional control, making it ideal for complex trajectories or horizontal drilling, especially in challenging formations.

2. Vibration Control

Straight blade stabilizers provide moderate vibration reduction by keeping the drill string aligned, but they may transmit torsional oscillations in high-speed or abrasive formations. They perform best in stable or soft geological conditions where minimal vibration occurs.

Spiral stabilizers excel in vibration absorption. The helical blades dissipate torsional and lateral forces along the drill string, reducing shock, minimizing tool wear, and allowing smoother drilling. This advantage is critical in hard, abrasive, or highly deviated wells where vibration can affect accuracy and tool longevity.

3. Directional Control

Straight blade stabilizers offer basic directional control, sufficient for vertical or slightly deviated wells. They maintain borehole alignment but may struggle to prevent doglegs in highly deviated or horizontal wells.

Spiral stabilizers provide superior directional control due to their twisted blade configuration. They guide the drill string smoothly, reduce tendency for lateral deviation, and maintain precise borehole trajectories in directional and horizontal drilling operations, enhancing drilling efficiency and safety.

4. Hole Cleaning Efficiency

Straight blade stabilizers allow some mud flow along the borehole but may not optimize cuttings removal. In long or deviated wells, straight blades can allow accumulation of debris, potentially slowing drilling progress and increasing maintenance needs.

Spiral stabilizers enhance hole cleaning by promoting a consistent flow path for drilling fluid. The helical blades facilitate cuttings removal, reduce sticking, and prevent accumulation, improving penetration rates and reducing operational downtime in deep or directional wells.

5. Application Versatility

Straight blade stabilizers are suitable for vertical and mildly deviated wells in oil, gas, geothermal, and mining operations. They are cost-effective, reliable, and easy to maintain, ideal for simple drilling projects.

Spiral stabilizers are versatile for vertical, directional, and horizontal wells. Their design adapts to challenging formations, minimizes vibration, and improves hole cleaning. They are preferred in complex or extended-reach drilling projects where precision and efficiency are critical.

Here are some differences between straight blade stabilizers and spiral blade stabilizers:

| Aspect | Straight Blade Stabilizer | Spiral Blade Stabilizer |

|---|---|---|

| Blade Design | Parallel, uniform blades | Twisted, helical blades |

| Vibration Control | Moderate | Excellent |

| Directional Control | Basic | Superior |

| Hole Cleaning | Standard | Enhanced |

| Application | Vertical, mild deviation | Vertical, directional, horizontal |

How to Choose Straight and Spiral Blade Stabilizers?

Choosing the right stabilizer is critical for optimizing drilling performance, reducing vibration, and ensuring wellbore stability. Straight and spiral blade stabilizers offer different advantages depending on wellbore conditions, trajectory, and formation type. Understanding their differences helps drillers select the most suitable stabilizer for efficient, safe, and cost-effective operations.

- Assess Wellbore Trajectory: Evaluate whether the well is vertical, directional, or horizontal. Straight blade stabilizers work well for vertical or slightly deviated wells, while spiral blades are ideal for complex, highly deviated, or horizontal wells where enhanced directional control is needed.

- Consider Formation Type: Analyze the hardness, abrasiveness, and stability of the formation. Spiral blade stabilizers are better for hard or abrasive formations due to their vibration reduction and superior hole cleaning, while straight blades are suitable for softer, stable formations.

- Evaluate Drilling Depth: Deep wells may require stabilizers with enhanced wear resistance and vibration control. Spiral stabilizers provide smoother torque transmission in deep, long-reach wells, whereas straight blades suffice for shallow or moderate-depth wells with simpler drilling requirements.

- Tool Life and Maintenance: Consider the ease of maintenance and expected tool lifespan. Straight blade stabilizers are simpler to manufacture and maintain, while spiral blades, though more complex, offer longer tool life due to reduced vibration and optimized load distribution.

- Cost vs Performance: Assess your project budget relative to desired drilling performance. Straight blade stabilizers are generally more cost-effective and reliable for simple wells, while spiral stabilizers, though higher in cost, deliver superior control, efficiency, and reduced downtime in challenging drilling conditions.

Conclusion

Straight blade and spiral stabilizers each serve specific purposes in drilling operations. Straight blades are best for straightforward, stable wells, offering durability and simplicity, while spiral blades provide better vibration reduction and directional control for complex trajectories. Understanding these differences ensures improved drilling efficiency and wellbore quality.

Selecting the right stabilizer depends on your wellbore conditions, drilling depth, and project goals. By evaluating formation type, trajectory, and tool requirements, drillers can choose the stabilizer that maximizes performance, reduces wear, and ensures safer and more cost-effective operations in oil, gas, mining, or geothermal applications.

For reliable drilling stabilizers, trust Sinodrills. We offer wholesale straight blade, spiral, and other types of stabilizers designed for durability, precision, and optimal performance. With customizable options and strict quality control, Sinodrills provides the ideal solutions to meet your drilling challenges and boost project efficiency.