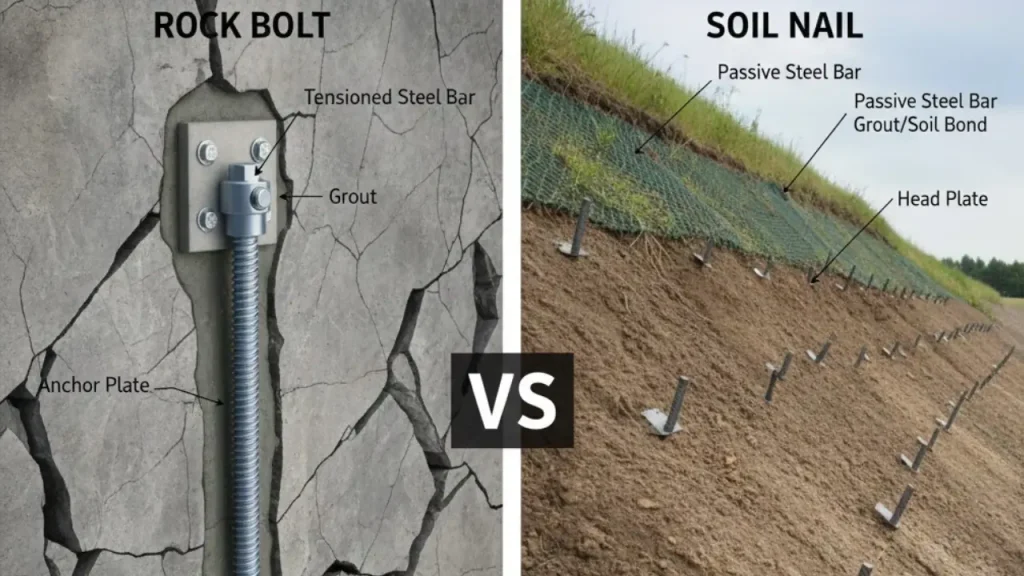

Rock bolts and soil nails are both essential ground reinforcement techniques, but they serve different purposes in construction and mining. Rock bolts stabilize solid or fractured rock formations, while soil nails reinforce weaker soils. Understanding their differences helps engineers select the right method for safety, stability, and long-term structural performance.

The installation methods, materials, and applications vary between rock bolts and soil nails. Rock bolts often require drilled holes and grouting in hard rock, whereas soil nails use flexible reinforcement in softer soils. Choosing the appropriate solution ensures cost-effective, efficient, and durable support for tunnels, slopes, excavations, and retaining structures.

What is a Rock Bolt?

A rock bolt is a structural element used to stabilize rock formations in tunnels, slopes, and underground excavations. It works by anchoring loose or fractured rock to more stable surrounding material, preventing collapse and improving load distribution. Rock bolts are essential for safety and long-term stability in construction and mining projects.

- Enhanced Structural Stability: Rock bolts transfer loads from unstable rock to more competent surrounding layers, reducing the risk of collapse. This reinforcement ensures that tunnels, mines, and slopes remain safe and structurally sound under varying geological and environmental conditions.

- Improved Safety: By preventing rock falls and wall movement, rock bolts protect workers, machinery, and infrastructure. Their use minimizes accidents in hazardous underground or surface environments, providing reliable support during construction or mining operations.

- Cost-Effective Solution: Rock bolts offer a durable method of stabilization without extensive excavation or additional support structures. This reduces material, labor, and maintenance costs while providing long-term reinforcement that adapts to changing rock conditions.

- Versatile Applications: Suitable for tunnels, shafts, slopes, and retaining walls, rock bolts can be tailored to different rock types and stress conditions. Their adaptability makes them a preferred choice for a wide range of civil engineering and mining projects.

What is a Soil Nail?

A soil nail is a steel rod or bar inserted into pre-drilled holes in soil or weak rock to reinforce and stabilize slopes, excavations, or retaining walls. Once grouted in place, it strengthens the soil mass, prevents collapse, and enhances load-bearing capacity, providing long-term stability for construction and geotechnical projects.

- Slope Stabilization: Soil nails reinforce slopes, preventing landslides and erosion. They distribute loads evenly across unstable soil layers, reducing movement and maintaining stability even in steep or soft terrain, which protects infrastructure and enhances site safety over time.

- Excavation Support: Soil nails provide temporary or permanent support for excavations, preventing wall collapse and soil movement. They allow construction of basements, tunnels, and underground facilities safely, minimizing risks, reducing downtime, and ensuring structural integrity in challenging soil conditions.

- Cost-Effective Reinforcement: Installing soil nails is often more economical than traditional retaining structures. They require less material, less excavation, and reduced labor, making them a practical choice for projects where budget efficiency is crucial without compromising safety or long-term performance.

- Adaptable to Various Soil Types: Soil nails can be tailored for different soil conditions, including cohesive, granular, or layered soils. Nail length, spacing, and grouting methods can be adjusted to ensure optimal reinforcement, making the technique versatile across multiple geotechnical applications.

Rock Bolt vs Soil Nail

Rock bolts and soil nails are ground reinforcement techniques used in construction and mining, but they differ in materials, installation, and applications. Understanding their differences helps engineers select the most effective solution for stabilizing rock formations or weak soil. Both methods improve safety, prevent collapse, and enhance load-bearing capacity.

1. Material and Design

Rock bolts are typically made of high-strength steel and designed to anchor into solid or fractured rock. They often include mechanical or grouted anchorage for long-term stability.

Soil nails are steel rods inserted into soil or weak rock and grouted to reinforce and stabilize the soil mass. They are flexible and adaptable to varying soil conditions, providing support in soft or loose soils.

2. Installation Method

Rock bolts require drilled holes in competent rock, often followed by grouting or mechanical expansion for anchorage. Installation demands precision and is suited for tunnels, mines, and hard rock slopes.

Soil nails involve drilling into soil or weak ground, inserting steel bars, and grouting them in place. Facing materials like shotcrete may be applied. The method supports slopes, retaining walls, and excavations efficiently.

3. Load Distribution

Rock bolts transfer loads from unstable rock to more stable surrounding material. They are ideal for high-stress environments and provide strong anchorage in fractured or solid rock.

Soil nails distribute loads across the reinforced soil mass, improving cohesion and slope stability. They are more suitable for low- to medium-stress soil environments, where flexibility and gradual reinforcement are important.

4. Applications

Rock bolts are commonly used in tunnel construction, underground mining, and rock face stabilization. They provide immediate and long-term support in hard rock conditions.

Soil nails are applied in slope stabilization, retaining wall reinforcement, and excavation support. They are ideal for soft soil, urban construction, and temporary or permanent slope reinforcement projects.

5. Cost and Efficiency

Rock bolts may require higher installation costs due to drilling in hard rock and precision requirements but offer long-term durability.

Soil nailing is often more cost-effective, requiring less excavation and material, and can be installed faster in soft or unstable soils, providing practical reinforcement without extensive infrastructure.

| Aspect | Rock Bolt | Soil Nail |

|---|---|---|

| Material & Design | High-strength steel, mechanical or grouted anchorage | Steel rods, flexible, grouted into soil |

| Installation Method | Drilled into competent rock, grouted or expanded | Drilled into soil, grouted, often with facing |

| Load Distribution | Transfers load to stable rock, high-stress support | Distributes load across reinforced soil, moderate stress |

| Applications | Tunnels, mines, rock face stabilization | Slopes, retaining walls, excavations |

| Cost & Efficiency | Higher cost, long-term durability | Cost-effective, faster installation in soft soils |

How to Choose Rock Bolt and Soil Nail?

Selecting between a rock bolt and a soil nail depends on ground conditions, load requirements, and project goals. Understanding each method’s advantages ensures safety, efficiency, and long-term stability. Proper evaluation of soil or rock type, structural needs, and installation feasibility helps engineers make the right reinforcement choice.

- Assess Ground Conditions: Evaluate whether the site consists of solid rock, fractured rock, or soft soil. Rock bolts perform best in competent rock, while soil nails are suited for weaker soils. Proper assessment ensures the chosen method provides optimal anchorage and stability.

- Determine Load Requirements: Analyze expected loads and stress levels on the structure or slope. High-stress areas or deep tunnels may require rock bolts, whereas moderate-load slopes or retaining walls can benefit from soil nails, ensuring efficient load distribution and structural safety.

- Consider Installation Constraints: Account for accessibility, space limitations, and equipment availability. Soil nailing often requires less heavy machinery and can be installed in confined urban sites, while rock bolts may need specialized drilling equipment and more precise placement in hard rock conditions.

- Evaluate Project Duration and Cost: Compare installation time, material requirements, and budget constraints. Soil nailing is often faster and more cost-effective in soft soils, whereas rock bolts, though potentially more expensive, provide durable, long-term support in challenging rock formations.

- Review Maintenance and Longevity Needs: Consider long-term performance and environmental conditions. Rock bolts offer excellent durability in harsh, stable rock, while soil nails may require facing or drainage systems to maintain stability in softer, water-prone soils over time.

Conclusion

In conclusion, recognizing the differences between rock bolts and soil nails is key for project safety and efficiency. Rock bolts are ideal for competent rock stabilization, while soil nails are better suited for weaker soils or slopes. For reliable reinforcement solutions, Sinodrills offers wholesale rock drilling tools to support your projects.

Our rock drilling tools simplify the installation of both rock bolts and soil nails, ensuring accurate placement, strong anchorage, and long-term performance. Partnering with Sinodrills guarantees access to durable, high-quality tools that meet diverse construction, mining, and civil engineering requirements efficiently.

By choosing Sinodrills for your drilling and reinforcement needs, you benefit from expert guidance, customizable solutions, and products engineered for safety and reliability. Get your wholesale rock drilling tools today to enhance the stability, durability, and efficiency of every project.