A casing shoe is one of those small but critical components that keeps drilling operations steady, protected, and moving forward. Whether you’re working in mining, construction, or geotechnical drilling, the casing shoe sets the tone for how well your casing string enters and withstands the formation ahead.

In this ultimate guide, we’ll walk through what a casing shoe is, how it works, the different types available, and why choosing the right one matters. From durability to formation protection to drilling efficiency, understanding casing shoes helps you make smarter decisions for safer, smoother drilling performance.

What is Casing Shoe?

A casing shoe is a hardened guide installed at the bottom of a casing string to help it enter the ground smoothly during drilling. It protects the casing from damage, reduces friction, and allows the string to pass through mixed or hard formations more easily, improving safety and drilling efficiency.

What is Casing Shoe Used for?

A casing shoe is used to guide and protect the casing string as it enters the ground, ensuring smooth and controlled drilling. It strengthens the casing’s leading edge, reduces friction, and allows the string to pass through difficult formations without damage while maintaining stability and safety.

- Guiding the casing string: The casing shoe ensures smooth, straight entry of the casing into the formation, preventing misalignment or snagging. Its tapered design reduces resistance, improves control, and supports accurate installation even in rocky or uneven ground, making the drilling process more efficient and predictable.

- Protecting the casing from abrasion: The shoe absorbs friction and impact as the casing passes through soil or rock, preventing wear or deformation of the casing body. This reduces maintenance costs, extends the casing’s life, and ensures continuous drilling even in abrasive or challenging formations.

- Improving penetration in hard formations: Hardened or carbide-reinforced casing shoes help the casing push through dense or mixed geological layers smoothly. This minimizes torque stress, maintains consistent drilling progress, and allows safe advancement through soft soils and hard rock without damaging the casing.

- Supporting drilling stability: The casing shoe maintains alignment and reduces vibration or wobbling, ensuring accurate hole progression. This stability protects drilling tools and the casing, reduces equipment strain, and improves operational efficiency in challenging drilling conditions.

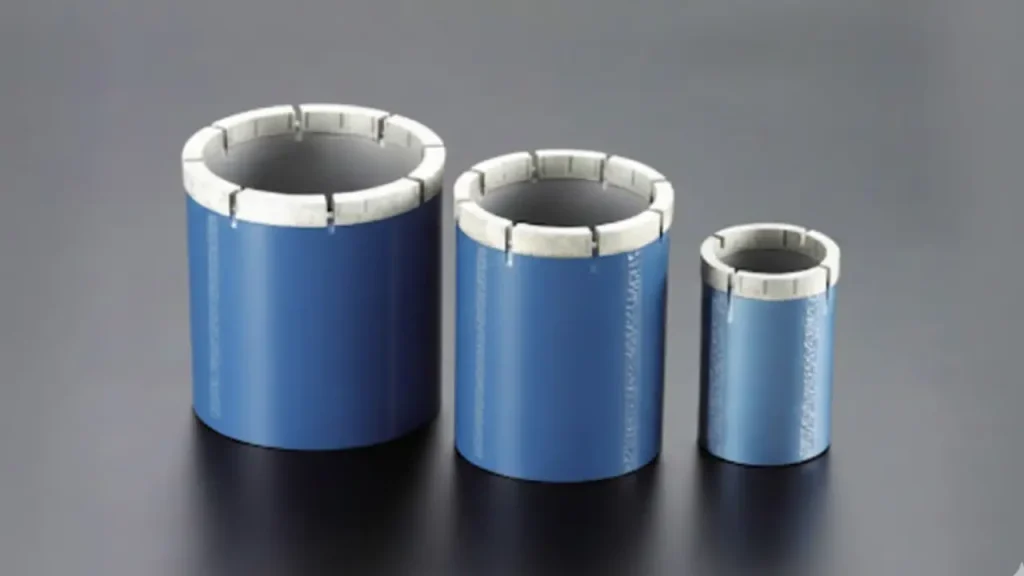

Types of Casing Shoe

Casing shoes come in different designs to suit varying drilling conditions and formation types. Choosing the right type ensures smoother casing installation, reduced wear, and improved drilling efficiency. This section covers the most common casing shoe types and their applications, helping you select the best option for your project needs.

Solid Casing Shoe

A solid casing shoe is a one-piece, durable component that protects the casing’s leading edge and guides it through the formation. It is simple in design, making it reliable for standard drilling operations, especially in soft to medium-hard formations. Its robustness minimizes deformation and ensures consistent alignment.

Solid casing shoes are widely used due to their cost-effectiveness and ease of installation. They provide steady penetration, reduce friction, and are less likely to get stuck in mixed formations. Maintenance is minimal, and their solid structure allows them to handle moderate impact during drilling.

Carbide-Tipped Casing Shoe

Carbide-tipped casing shoes feature hardened tips that can penetrate tough, abrasive formations more easily than standard shoes. They are designed to improve drilling efficiency in hard rock layers while reducing wear on the casing itself. These shoes are ideal for challenging geological conditions.

The carbide tip absorbs most of the friction and cutting forces, extending the shoe’s service life and maintaining smooth casing advancement. They are highly durable, offer superior penetration, and reduce the risk of downtime caused by wear or damage to the casing during drilling operations.

Expandable Casing Shoe

Expandable casing shoes allow slight diameter adjustments to accommodate irregular or unstable formations. They help maintain casing alignment and prevent sticking in loose or collapsing soils. These shoes provide flexibility and improved stability in complex drilling scenarios.

Expandable casing shoes are often used in geotechnical or offshore drilling where formations vary unpredictably. Their design reduces friction and allows the casing to adapt to formation changes, ensuring safer operations. They also improve sealing and reduce the risk of borehole collapse, making them suitable for sensitive projects.

Open-End Casing Shoe

Open-end casing shoes feature a hollow or partially open design to facilitate fluid flow during drilling. They guide the casing while allowing drilling mud or other fluids to circulate freely, reducing pressure build-up and maintaining borehole stability.

These casing shoes are preferred in applications where fluid circulation is critical for cooling, lubrication, or debris removal. They minimize obstruction, help prevent stuck casing, and enhance overall drilling efficiency. Open-end shoes are often combined with reaming systems for smooth penetration through mixed formations.

How to Choose Suitable Casing Shoes?

Selecting the right casing shoe is crucial for efficient drilling, reduced wear, and project safety. Factors such as formation type, drilling depth, and operational conditions determine which shoe will provide the best performance. Understanding key considerations helps you make an informed choice that ensures smoother casing installation and long-term durability.

- Consider the formation type: Different geological formations require specific casing shoes. Soft soils may only need standard solid shoes, while hard rock or abrasive layers benefit from carbide-tipped or reinforced designs. Choosing based on formation ensures smooth penetration, prevents casing damage, and maintains drilling stability throughout the project.

- Evaluate the drilling depth: Deep wells generate higher stress and friction on casing shoes. For shallow applications, standard shoes may suffice, but deeper wells often require durable or reinforced shoes to maintain alignment, minimize wear, and prevent stuck casing. Depth assessment ensures long-lasting performance and operational efficiency.

- Assess operational conditions: Drilling conditions such as fluid type, torque, vibration, and borehole stability influence shoe selection. Shoes with specific coatings, open-end designs, or expandable features can handle challenging conditions better. Proper assessment reduces downtime, protects equipment, and supports consistent drilling progress in variable environments.

- Check compatibility with casing system: Ensure the shoe matches the diameter, thread type, and material of your casing string. Compatibility avoids installation issues, prevents leaks or misalignment, and allows smooth operation. A well-matched shoe optimizes both safety and efficiency for every drilling scenario.

- Consider durability and maintenance: Shoes designed for wear resistance and long service life reduce maintenance needs and lower replacement costs. Features like carbide tips, reinforced bodies, or corrosion-resistant materials extend operational life. Prioritizing durability ensures reliable performance and minimizes disruptions during drilling operations.

Conclusion

Casing shoes may seem simple, but they play a huge role in keeping your drilling operations protected from unpredictable ground conditions. The right design improves penetration, protects the casing, and minimizes the risks associated with entering mixed or difficult formations. Knowing how they function ensures you maintain both safety and efficiency on every project.

As you evaluate casing shoes, consider factors like formation hardness, shoe material, wear resistance, and alignment with your casing system. A well-matched casing shoe reduces downtime, lowers tool damage, and improves project outcomes. Investing in dependable shoes means investing in long-term stability for your drilling work.

If you’re ready to source reliable, durable casing systems for upcoming drilling jobs, Sinodrills offers dependable options built for real-world performance. From casing shoes to complete casing systems, we support wholesalers, contractors, and drilling teams worldwide. Explore our wholesale casing solutions to upgrade your equipment and keep every drilling operation running smoothly.