Custom Cross Drill Bit Manufacturer in China

We offer a premium Cross Drill Bit designed for exceptional accuracy and durability. Ideal for precise drilling in various materials, this bit ensures clean, burr-free holes with every use. Its unique design allows for versatile applications, making it an essential tool for professionals. Experience superior performance and achieve flawless results.

Sinodrills - Your Trusted Cross Drill Bit Manufacturer from China

Sinodrills, a trusted drill bit manufacturer from China, offers superior drilling solutions. With over two decades of expertise, we specialize in high-quality cross drill bits made from premium alloy steels and carbides, ensuring exceptional accuracy and durability. Our commitment to innovation, stringent ISO9001 quality control, and CE certification guarantee reliable performance for mining, construction, and quarrying projects worldwide.

Various Cross Drill Bit

threaded cross drill bit with normal skirt

We provide high-performance threaded cross drill bits with a normal skirt, specifically designed for drilling in very hard and abrasive rock formations. Our bits feature premium alloy buttons, hot-mounted for superior accuracy and durability. Available in various thread sizes (R25, R28, R32, R38, T38) and head diameters, these cost-effective tools ensure high speed and drilling efficiency for mining, construction, and quarrying applications.

PDC cross drill bit for oil well drilling

We provide advanced PDC (Polycrystalline Diamond Compact) cross drill bits specifically engineered for demanding oil well drilling. Our bits feature superior diamond cutters and robust body designs, ensuring exceptional penetration rates and extended tool life in various geological formations, from soft shale to hard, abrasive rock. Trust our PDC cross drill bits for increased efficiency, reduced drilling costs, and optimal performance in your oil and gas operations.

3 part cross drill bit for water well drilling

We provide high-performance 3-part cross drill bits specifically engineered for water well drilling. These robust bits feature a multi-wing design for optimal penetration and efficient cutting in diverse ground formations, including soil, sand, and soft rock. Crafted from wear-resistant materials, our bits ensure extended lifespan and reliable performance, contributing to faster and more cost-effective water well construction.

steel carbide tipped cross drill bit

We provide high-performance steel carbide tipped cross drill bits, engineered for unmatched durability and precision. These bits feature robust steel bodies with brazed carbide tips, offering superior hardness and wear resistance. Ideal for drilling through tough materials like hardened steel, concrete, and masonry, they ensure clean, efficient holes and extended tool life. Experience enhanced productivity and reliability with our cutting-edge drilling solutions.

cross type bit tapered connection cross bit

We provide well-designed cross type bits with tapered connections, engineered for demanding rock drilling applications. Our tapered cross bits offer superior penetration and durability in hard or very hard rock formations. Available in various taper degrees and diameters, they are ideal for mining, quarrying, tunneling, and construction projects, ensuring optimal performance and extended service life.

SDA cross drill bits for rock drilling

We offer SDA cross drill bits designed for efficient rock drilling in mining, construction, and tunneling projects. With durable materials, precise cutting edges, and customizable sizes, we provide reliable, long-lasting, and high-performance solutions to enhance productivity and ensure smooth, accurate drilling operations.

drag type cross drill bit for rock drilling

We provide drag type cross drill bits, ideal for rock drilling in softer to medium-hard formations like clay, shale, and soft limestone. These bits are designed for efficient penetration and offer excellent performance in applications such as water well drilling, mining, and exploration. Our drag bits feature robust construction and durable carbide tips, ensuring a longer lifespan and consistent drilling results.

H thread cross type drill bits

We provide premium H thread cross type drill bits engineered for heavy-duty rock and concrete drilling. Built with durable materials and precise cutting edges, they ensure efficient penetration, long-lasting performance, and consistent results. Our customizable options help meet diverse project requirements, improving productivity and reliability across mining, construction, and tunneling applications.

wholesale cross drill bits for quarry

We provide cross drill bits designed for heavy-duty quarry operations. Made from durable materials with precise cutting edges, our drill bits ensure efficient rock penetration, long-lasting performance, and reduced downtime. Available in various sizes and configurations, they deliver reliable, high-performance solutions tailored to meet the demanding needs of quarrying projects.

chisel bit cross drill bits for mining

Chisel bit cross drill bits for mining are designed for fast penetration and stable drilling in hard rock. We offer durable alloys, precise geometry, and consistent performance. Our bits reduce deviation, improve flushing, and extend service life across underground and surface mining applications worldwide, with flexible sizes and custom options.

X type drill bits

We offer X type drill bits designed for fast penetration and stable drilling performance. The X-shaped head improves cutting efficiency, reduces deviation, and enhances hole accuracy. Made from durable alloy steel, our X type drill bits deliver long service life and reliable results in mining, construction, and foundation drilling applications.

Customize Your Desired Cross Drill Bit

Material Composition

We offer a range of premium materials for your cross drill bits, primarily high-quality alloy steels and tungsten carbide. The choice depends on the rock formation you’re drilling. For softer, abrasive conditions, certain steel alloys excel, while harder, more challenging rock demands the superior wear resistance of carbide inserts. We work with you to select the best material for durability and sustained performance.

Bit Diameter and Taper Angle

We can customize the bit diameter to match your required hole size, from smaller holes for light drilling to larger ones for heavy-duty quarrying. Additionally, the taper angle, which influences how the bit connects to the drill steel, is critical for efficient energy transfer and bit stability. We provide various taper angles (e.g., 4°, 6°, 7°, 11°, 12°) to optimize compatibility with your drilling rig.

Carbide Insert Shape and Configuration

The shape and arrangement of the carbide inserts directly impact drilling performance. We can offer cross bits with different insert configurations, such as full carbide cross or shallow carbide cross, and even explore button bit designs for specific conditions. Each design is optimized for factors like penetration rate, hole straightness, and resistance to wear in various rock types.

Flushing Hole Design

Effective flushing is vital for removing cuttings and preventing bit overheating. We can customize the number, size, and position of flushing holes on your cross drill bit. This ensures efficient debris evacuation and continuous coolant flow, which is particularly important in challenging drilling environments where high temperatures and sticky formations can impede progress.

what is a cross drill bit?

A cross drill bit, often referred to as a crosshead or cruciform tip bit, is a type of drill bit characterized by its four cutting edges arranged in a “cross” shape at the tip.

This design provides increased stability and efficiency, particularly when drilling into hard and abrasive materials like concrete, brick, and rock.

The multiple cutting edges help distribute the load, reduce vibration, and facilitate faster removal of drilling debris, resulting in cleaner and more accurate holes compared to bits with fewer cutting points. These bits are commonly used in various applications, from construction and mining to general masonry work.

cross drill bit benefits

Cross drill bits offer significant advantages, especially in challenging drilling applications. Their distinctive “cross” shaped cutting head, typically with four carbide inserts, provides a more aggressive and stable drilling action compared to conventional two-point bits.

This design helps to distribute the cutting forces more evenly, reducing the stress on individual cutting edges and minimizing vibration during operation. This translates to a smoother drilling experience, better control, and ultimately, higher quality holes.

The benefits of utilizing cross drill bits are numerous, making them a preferred choice for professionals in mining, construction, and quarrying.

- Enhanced Penetration Rate: The four cutting points break rock or material more efficiently, leading to faster drilling speeds and improved productivity.

- Superior Hole Straightness: The balanced cutting action minimizes bit deviation, resulting in straighter and more accurate boreholes, crucial for precise blasting or structural integrity.

- Increased Bit Life: By distributing wear across four edges, the carbide inserts or steel body of the bit experience less localized stress, extending the overall lifespan of the drill bit. This reduces downtime for bit changes and lowers operational costs.

- Improved Flushing: The cross design often incorporates optimized flushing channels, which effectively remove cuttings and debris from the hole. This prevents jamming, reduces overheating, and maintains a clean drilling environment.

- Versatility: Cross drill bits are highly versatile and perform well across a wide range of rock formations, from soft to medium-hard, making them a reliable choice for diverse drilling projects.

cross drill bit types

While all cross drill bits share the fundamental four-cutting-edge design, variations exist, primarily in their shank type, carbide insert configuration, and overall construction, to optimize them for different drilling tasks and rock conditions.

Understanding these distinctions is crucial for selecting the most effective bit for your application.

Here are the main types and variations of cross drill bits:

Tapered Cross Bits: These are a common type of cross drill bit that features a tapered connection to the drill rod. The angle of the taper (e.g., 4°, 6°, 7°, 11°, 12°) is crucial for how the bit connects to the drill steel and for efficient energy transfer. They are widely used in small-hole rock drilling, quarrying, and mining applications.

Threaded Cross Bits: Unlike tapered bits, these bits have a threaded connection to the drill steel. This design ensures a secure and robust connection, making them suitable for heavier-duty drilling applications where higher torque and impact forces are involved. Different thread sizes (e.g., R25, R32) are available to match various drill steels and applications.

Full Carbide Cross Bits: This variation refers to the design of the carbide inserts at the bit’s tip. Full carbide cross bits have four substantial carbide inserts that form the cross pattern. These bits are known for their exceptional durability and aggressive cutting action in hard rock formations, offering excellent gauge holding and the ability to be resharpened.

Shallow Carbide Cross Bits (Economy Cross Bits): These bits have smaller or “shallower” carbide inserts compared to full carbide cross bits. While they may be more economical, they generally offer less wear resistance in very hard or abrasive conditions. They are often used for smaller jobs or in situations where bit failure is a higher risk, as their lower cost can make replacement more feasible.

Drag Type Cross Bits: While all cross bits are technically a type of drag bit (meaning they scrape and cut the rock), “drag type” specifically refers to bits designed for drilling in softer, less consolidated formations like clay, shale, or soft limestone. Their primary mechanism is scraping and shearing, and they often have a less robust carbide configuration than those meant for hard rock, focusing on efficient penetration in these softer materials.

SDS Plus and SDS Max Cross Bits: These types primarily refer to the shank design, which dictates compatibility with specific rotary hammer drills.

- SDS Plus Cross Bits: Feature a 10mm shank with four grooves, suitable for lighter to medium-duty drilling in masonry, concrete, and brick.

- SDS Max Cross Bits: Have an 18mm shank with three open grooves and two closed grooves, designed for heavier-duty drilling and larger diameter holes in tougher masonry and concrete, offering increased torsional strength.

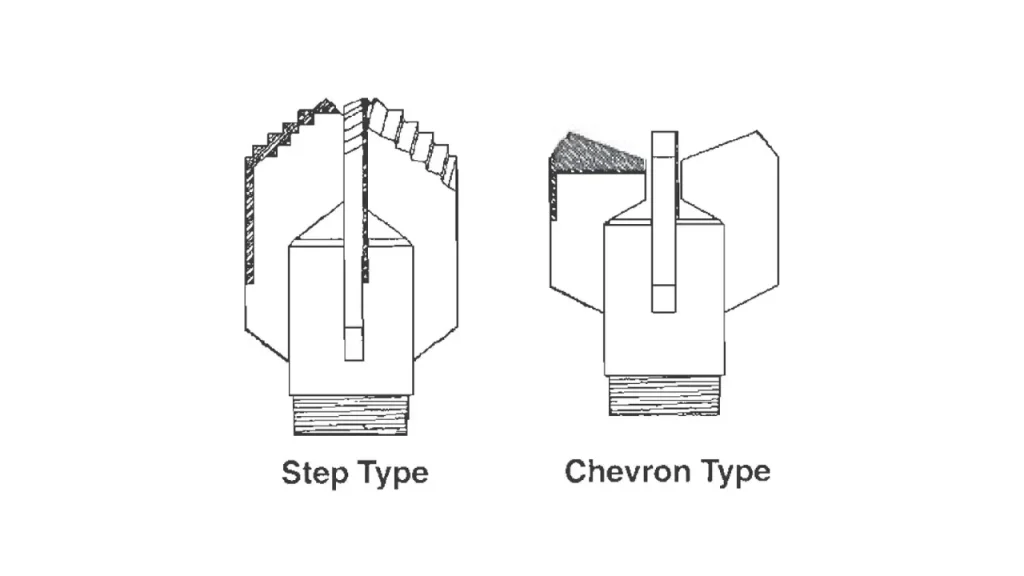

chevron drag bit vs step

When discussing drag bits for rock drilling, two of the most common types are chevron drag bits and step drag bits.

Both are designed to cut through rock by scraping and shearing, making them ideal for softer to medium-hard formations. However, their distinct cutting structures lead to different performance characteristics and preferred applications.

Here are the differences between chevron and step drag bits:

Chevron Drag Bits

- Cutting Structure: Chevron drag bits feature cutting wings that are typically pointed at the tip and widen towards the base, forming a “chevron” or V-shape. These wings are arranged radially around a central opening. They often have robust carbide inserts at the tips to enhance durability.

- Ideal Formations: Chevron bits are generally designed for drilling in medium to hard formations, including hard shales, limestones, soft sandstones, and even for drilling through concrete casings and plugs. Their more durable cutting structure allows them to withstand more abrasive conditions.

- Penetration Rate & Durability: While they are more durable and can handle tougher formations, chevron bits tend to have a slower penetration rate compared to step bits. They require more weight on the bit (WOB) to achieve optimal drilling.

- Cuttings: They generally produce smaller, finer cuttings due to their more aggressive and durable cutting action.

- Applications: Commonly used in areas with rocky formations, water well drilling, mining, and situations where drilling out concrete or plugs is necessary.

Step Drag Bits

- Cutting Structure: Step drag bits, as their name suggests, have a “stair-stepped” or tiered cutting structure. The cutting elements are typically pointed at the top and then gradually widen in steps down towards the base of the bit. They can have three or four wings.

- Ideal Formations: Step bits are best suited for drilling in soft to medium-soft formations, such as sands, clays, unconsolidated gravels, and soft limestones. Their design allows for aggressive cutting in these less consolidated materials.

- Penetration Rate & Durability: They are known for their faster penetration rates in soft formations, as their aggressive cutting structure produces larger cuttings quickly. However, this aggressive design also makes them generally less durable than chevron bits, especially in harder or very abrasive conditions.

- Cuttings: Step bits produce larger cuttings, which can be advantageous for logging or examining geological samples.

- Applications: Widely used in water well drilling, environmental drilling, exploration, and for drilling pilot holes in soft overburden. They are excellent when a high rate of penetration is prioritized in soft ground.

Send Your Inquiry Now

All-in-one Cross Drill Bit Solutions for Your Project

Sinodrills offers all-in-one cross drill bit solutions tailored for diverse projects. We provide high-quality cross bits with customizable material compositions, diameters, taper angles, and carbide insert configurations to optimize performance in various rock formations. Our bits ensure superior penetration, hole straightness, and extended lifespan, backed by over two decades of manufacturing expertise and stringent quality control.