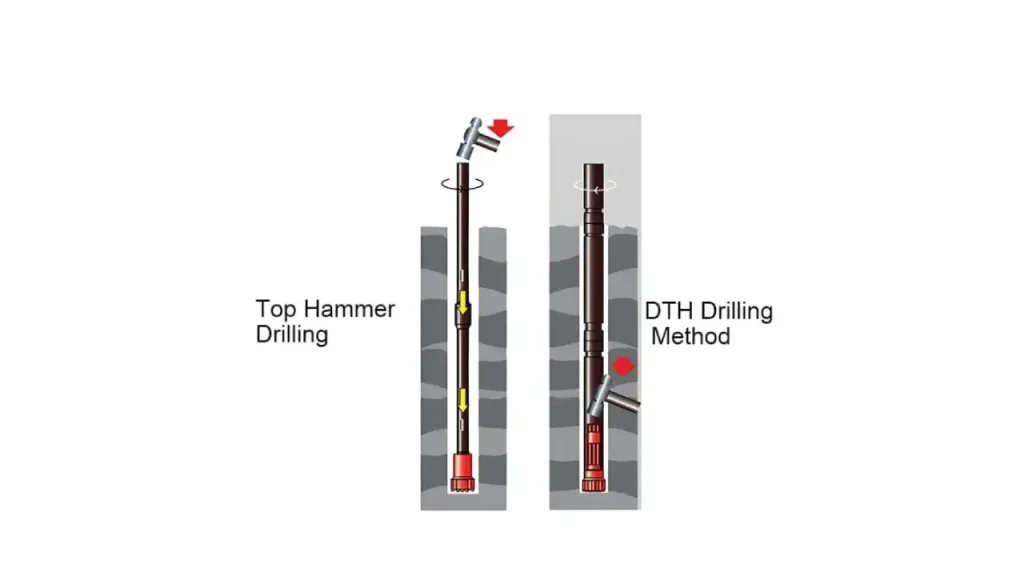

Understanding the distinct drilling mechanisms of DTH (Down-The-Hole) and Top Hammer rigs is crucial for optimizing your drilling operations. Both methods are widely employed across various industries, from mining to construction, yet they differ fundamentally in how they deliver percussive energy to the rock. This blog post will delve into their core operational principles and key differentiating factors.

We will explore how DTH hammers generate impact at the bottom of the hole, close to the drill bit, leading to specific advantages in certain geological conditions. Conversely, we will examine how Top Hammer drills transmit impact energy from the surface, through the drill string. By understanding these differences, you can make informed decisions to select the most efficient and cost-effective drilling method for your project’s unique requirements.

What are DTH Hammers?

Recommended DTH Hammers

A DTH (Down-The-Hole) hammer is a powerful percussion drilling tool used across various industries, including mining, construction, and water well drilling. It operates by delivering rapid, high-energy impacts directly to a drill bit, effectively breaking rock into small chips.

Unlike top hammer drills where the striking mechanism is at the surface, the DTH hammer is located at the bottom of the drill string, right behind the bit, which ensures highly efficient energy transfer and minimizes power loss, making it particularly effective for drilling straight holes in hard and abrasive rock formations.

The hammer’s internal piston is actuated by compressed air, striking an anvil that transmits the force to the drill bit, while the exhaust air flushes cuttings from the borehole.

DTH Hammer Uses

Recommended Top Hammers

DTH (Down-The-Hole) hammers are versatile tools employed across a wide array of industries due to their efficiency in penetrating hard rock formations. Their ability to deliver powerful, direct impacts at the bottom of the hole makes them indispensable for various drilling applications, including:

- Mining: Used extensively for blast hole drilling in open-pit and underground mines, creating boreholes for explosives to break up ore and rock.

- Construction: Essential for foundation drilling, piling, and pre-splitting in infrastructure projects, ensuring stable bases for buildings, bridges, and roads.

- Water Well Drilling: Highly effective in boring through various rock strata to access groundwater, providing reliable water sources for communities and agriculture.

- Quarrying: Employed for dimension stone quarrying and aggregate production, enabling the extraction of valuable rock materials efficiently.

- Geotechnical and Exploration Drilling: Utilized for core sampling and creating boreholes for geological surveys, providing critical data on subsurface conditions for engineering and resource assessment.

What are Top Hammers?

A Top Hammer, also known as a drifter or surface percussion drill, is a drilling method where the percussion mechanism is located on the drill rig, above the surface.

Unlike DTH hammers, the impact energy generated by the top hammer is transmitted down the drill string through threaded drill rods to the drill bit.

This method is highly versatile and commonly used for smaller diameter holes, shorter depths, and in applications like construction, quarrying, and foundation drilling, where mobility and adaptability to varying rock conditions are priorities. While it may experience greater energy loss over longer drill strings compared to DTH, its flexibility and ease of operation make it a preferred choice for many surface drilling projects.

Recommended Top Hammers

Top Hammer Uses

Top Hammer drills are highly adaptable tools utilized in numerous applications where their versatility and mobility are advantageous. Their percussive mechanism, located on the surface, allows for flexibility in various ground conditions and project sizes, making them a common sight in:

- Construction: Widely used for general construction projects, including site preparation, trenching, and utility installations, where smaller holes and frequent rig moves are common.

- Quarrying: Employed for bench drilling in aggregate quarries and dimension stone operations, where precise hole patterns and controlled blasting are essential for material extraction.

- Road Construction: Crucial for rock excavation in road building, enabling the creation of stable roadbeds and cuttings through challenging terrain.

- Foundations and Piling: Used for drilling anchor holes, micropiles, and small-diameter foundations, providing stability for structures in various ground conditions.

- Exploration and Geotechnical Drilling: Applied in shallow exploration programs and geotechnical investigations, where samples are needed at moderate depths to assess ground properties.

DTH vs Top Hammer

Understanding the core differences between DTH and Top Hammer drilling is essential for selecting the optimal method for your project. This comparison will highlight key distinctions in their operation, application, and overall performance characteristics.

Energy Transfer Mechanism

In DTH (Down-The-Hole) drilling, the percussion mechanism is located directly at the bottom of the borehole, inside the hammer. The compressed air drives a piston within the hammer, which directly strikes the drill bit. This direct transfer minimizes energy loss, making DTH highly efficient for deep holes and hard rock formations, as the impact energy is delivered precisely where it’s needed.

Conversely, Top Hammer drilling transmits impact energy from a percussive unit located on the surface, down the drill string to the bit. The energy travels through drill rods, which are threaded together. This indirect transfer can lead to significant energy losses over longer drill strings, especially in deeper holes, potentially reducing penetration rates in very hard rock compared to DTH.

Hole Straightness

DTH hammers are renowned for producing exceptionally straight holes, even in challenging ground conditions. Because the hammer is at the bottom of the hole, it acts as a guide, inherently helping to maintain the bore’s trajectory. This characteristic is particularly beneficial for applications requiring precise hole alignment, such as foundation drilling or blast hole patterns.

Top Hammer drilling can sometimes result in less straight holes, especially in uneven or fractured ground. The energy transfer through flexible drill rods can allow for more deviation, as the bit is not rigidly guided by the hammering unit at the bottom. While techniques exist to mitigate this, DTH generally offers superior hole straightness.

Depth Capability

DTH hammers are ideally suited for drilling deep holes. The direct energy transfer mechanism means that drilling deeper does not significantly diminish the impact energy delivered to the bit. This makes DTH the preferred choice for applications like deep water wells, large-scale mining operations, and geotechnical investigations requiring significant depth.

Top Hammer drills are generally more suitable for shallower holes. As hole depth increases, the number of drill rods required also increases, leading to greater energy loss and reduced efficiency. While they can drill to moderate depths, their performance significantly decreases compared to DTH hammers for very deep applications.

Drill Bit Life

DTH drilling often leads to longer drill bit life, particularly in abrasive or hard rock conditions. The high-frequency, direct impact action combined with efficient flushing clears cuttings effectively, reducing bit wear from regrinding. The controlled energy delivery also minimizes shock loads on the bit inserts.

Top Hammer drilling can sometimes lead to faster wear on drill bits, especially in hard or abrasive rock. The indirect energy transfer and potential for more erratic bit action can cause increased stress and abrasion on the bit inserts. Additionally, less efficient flushing in some cases can contribute to faster bit wear.

Noise Levels

DTH hammers generally produce less noise at the surface compared to top hammer drills. Since the percussion mechanism is located down in the borehole, much of the operational noise is muffled by the surrounding rock. This can be a significant advantage in urban environments or other noise-sensitive areas.

Top Hammer drills, with their percussive unit located at the surface, typically generate higher noise levels. The hammering action is exposed, leading to more airborne noise during operation. This often necessitates stricter noise control measures or limits on operating hours in residential or environmentally sensitive locations.

Here are the differences between DTH hammer and top hammers in the following:

| Aspect | DTH Hammer | Top Hammer |

| Energy Transfer | Direct (hammer at hole bottom) | Indirect (hammer at surface, via rods) |

| Hole Straightness | Excellent | Good to moderate (can deviate) |

| Depth Capability | Suited for deep holes | Suited for shallower to moderate holes |

| Drill Bit Life | Generally longer | Can be shorter (depending on conditions) |

| Noise Levels | Lower (muffled by ground) | Higher (percussion at surface) |

Top Hammer Drilling vs Down the Hole Drilling

Understanding the fundamental operational differences between DTH (Down-The-Hole) and Top Hammer drilling methods is crucial for optimizing project efficiency. This comparison delves into their distinct mechanics, suitability for various conditions, and overall performance characteristics, guiding optimal equipment selection.

Energy Transfer Mechanism

In DTH drilling, the percussive hammer is located directly at the bottom of the borehole, striking the drill bit from within. Compressed air powers a piston inside the hammer, transmitting energy directly to the rock. This direct impact minimizes energy loss as depth increases, ensuring consistent power for efficient rock breaking at any depth.

Conversely, Top Hammer drilling involves a percussive unit mounted on the drill rig at the surface. Impact energy is transmitted down the drill string through a series of threaded drill rods to the bit. This indirect energy transfer means power can diminish with increasing drill string length, affecting efficiency in deeper holes.

Hole Straightness

DTH hammers are renowned for their ability to produce exceptionally straight holes, even in challenging and variable rock formations. The hammer’s position at the bottom of the hole acts as a natural stabilizer, guiding the bit and minimizing deviation. This precision is critical for applications requiring strict borehole alignment, such as foundation work.

Top Hammer drilling, due to the energy being transmitted through flexible rods, can sometimes result in more hole deviation, particularly in fractured ground or over longer drilling lengths. While skilled operators can mitigate this, maintaining perfect straightness can be more challenging compared to the inherent stability offered by DTH.

Depth Capability

DTH drilling is the preferred method for deep holes, often exceeding hundreds of meters. The direct impact mechanism ensures that the effectiveness of the percussive action is maintained regardless of the depth. This makes DTH highly efficient for large-scale mining, deep water wells, and extensive geotechnical investigations.

Top Hammer drilling is generally more suitable for shallower holes, typically up to 20-30 meters, though this can vary. As depth increases, the energy loss through the longer drill string becomes more pronounced, leading to reduced penetration rates and efficiency. Its strength lies in quick setups for less demanding depths.

Bit Wear and Longevity

DTH drilling generally results in longer drill bit life, especially in very hard and abrasive rock. The efficient flushing system, coupled with the direct and consistent impact, reduces the risk of regrinding cuttings. This minimizes wear on carbide inserts, leading to extended service intervals and lower consumable costs.

Top Hammer drilling can, in some conditions, lead to faster drill bit wear. The indirect energy transfer may cause more erratic bit movement and increased stress on the cutting elements. Less efficient removal of cuttings in certain applications can also contribute to abrasive wear, necessitating more frequent bit changes.

Noise and Vibration

DTH hammers typically produce lower noise levels at the surface. Since the primary percussive action occurs deep within the borehole, much of the sound is absorbed and muffled by the surrounding rock and overburden. This makes DTH a more environmentally friendly option for noise-sensitive areas or urban projects.

Top Hammer drills tend to generate higher noise and vibration levels at the surface. The exposed percussive mechanism on the rig produces significant sound that propagates easily. This often requires stringent noise control measures, potentially impacting operational hours or requiring additional sound-dampening equipment in populated zones.

Application Focus

DTH drilling excels in applications requiring high penetration rates in very hard, competent rock, and where large-diameter, straight holes are critical. Its primary focus is on maximizing drilling efficiency and achieving precise boreholes in challenging geological conditions, making it ideal for deep mining and large construction.

Top Hammer drilling offers greater versatility for projects with varied rock conditions, smaller hole diameters, and frequent moves between drilling spots. It’s often chosen for surface applications like general construction, road building, and quarrying, where rapid setup, mobility, and adaptability to changing ground are key priorities.

Here are the differences between DTH drilling and top hammer drilling:

| Aspect | DTH Drilling | Top Hammer Drilling |

| Energy Transfer | Direct (hammer at hole bottom) | Indirect (hammer at surface, via rods) |

| Hole Straightness | Excellent, inherent guidance | Good, can be prone to deviation |

| Depth Capability | Ideal for deep holes (consistent efficiency) | Suited for shallower to moderate depths |

| Bit Wear & Longevity | Generally longer bit life, less regrinding | Can be faster bit wear, more abrasive action |

| Noise & Vibration | Lower surface noise (muffled by ground) | Higher surface noise and vibration |

| Application Focus | Hard rock, deep, straight, large holes | Varied rock, shallower, mobile, small-medium holes |

DTH vs Top Hammer Pros and Cons

Down the Hole (DTH) and Top Hammer are the two primary percussive drilling methods we utilize, each suited for vastly different applications. DTH, with the hammer located downhole, transfers maximum energy to the bit, which is crucial for deep holes and hard rock. We evaluate both techniques meticulously to determine the best approach for our client’s project goals.

Conversely, Top Hammer drilling operates with the hammer positioned at the top of the drill string, transmitting energy through the rods. This method is often preferred for shallower holes and specific rock types due to its speed and simplicity. We understand the distinct advantages and trade-offs of each system when planning an efficient drilling program.

Down the Hole (DTH) Drilling

- Pro: Superior Hole Straightness The hammer’s rigid placement near the bit minimizes rod flexing and deviation, enabling us to drill remarkably straight, deep holes. We leverage this precision for critical applications like long-hole production blasting and geotechnical anchoring, ensuring reliable placement.

- Con: Higher Initial Cost and Complexity: DTH systems require a larger, more powerful air compressor, leading to a higher initial equipment investment. The internal hammer components are also intricate, requiring specialized maintenance procedures that we must carefully manage to minimize operational delays.

- Pro: Excellent Energy Transfer: Because the hammer strikes the bit directly at the bottom of the hole, virtually no percussive energy is lost along the drill string. We achieve superior penetration rates in extremely hard or highly abrasive rock formations compared to surface-driven methods.

- Con: Larger Cuttings: The high-impact force tends to produce larger, less consistent rock cuttings. While the air flushing is effective, managing these larger fragments requires greater air volume, and they can occasionally cause blockages in challenging ground conditions.

Top Hammer Drilling

- Pro: Versatility and Accessibility: Top Hammer rigs are generally smaller, highly maneuverable, and faster to set up on site. We frequently use them for small-diameter holes, pre-splitting, and short bench drilling where ease of movement and rapid setup time are significant factors.

- Con: Energy Loss with Depth: Energy must travel through multiple rod connections before reaching the bit, which significantly reduces impact force in deep holes. We observe a noticeable drop in penetration rate as the depth and the total length of the drill string increase.

- Pro: Lower Air Consumption: Unlike DTH, which requires high-volume air for hammer action and flushing, Top Hammer drilling needs less compressed air. This allows us to use smaller, less expensive compressors, reducing the overall power consumption and fuel costs of the operation.

- Con: Increased Hole Deviation: The long, lightweight drill rods are prone to bending or walking off course, especially in fractured ground. We find that maintaining precise hole straightness can be challenging with this method, limiting its suitability for deep, long-hole projects.

| Feature Comparison | Down the Hole (DTH) | Top Hammer |

|---|---|---|

| Hammer Location | Bottom of the borehole | Surface (transfers through rods) |

| Ideal Depth Range | Deep holes (over 20 meters) | Shallow to medium holes (under 20 meters) |

| Energy Efficiency | High (direct impact, low loss) | Lower (significant energy loss in joints) |

| Hole Straightness | Excellent | Good (deviation increases with depth) |

| Initial Equipment Cost | Higher (due to large compressor) | Lower (simpler rig and compressor) |

How to Choose DTH and Top Hammers

Choosing between DTH (Down-The-Hole) and Top Hammer drilling methods requires careful consideration of several factors to ensure optimal efficiency and cost-effectiveness for your project. The decision hinges on understanding the specific demands of your application and the characteristics of the drilling environment.

Here are key aspects to consider when selecting between DTH and Top Hammer:

Geological Conditions:

- DTH: Ideal for very hard, abrasive rock formations where direct impact energy is most effective for penetration. It handles fractured or variable ground well due to constant bit-to-hammer contact, reducing energy loss.

- Top Hammer: Better suited for softer to medium-hard rock, or when drilling through varying strata with frequent changes. Its versatility allows for quick adjustments in different ground conditions.

Hole Depth and Diameter:

- DTH: Preferred for deep holes (over 20-30 meters) and larger diameters (typically 90mm and above). The direct energy transfer remains efficient even at great depths, ensuring consistent performance.

- Top Hammer: More effective for shallower holes (under 20-30 meters) and smaller to medium diameters. Energy loss increases with depth due to rods, limiting its efficiency for very deep applications.

Required Hole Straightness:

- DTH: Delivers superior hole straightness due to the hammer’s guiding action at the bottom of the hole. This is crucial for precision blasting, foundation piling, or any application requiring accurate bore alignment.

- Top Hammer: Can experience more deviation, especially in challenging ground or at greater depths, as the rods can flex. While good for general applications, it might not meet strict straightness requirements.

Mobility and Site Setup:

- DTH: Often requires larger, heavier rigs due to the need for higher air compression and larger drill string components. Setup can be more involved, but once operational, it’s highly efficient for its niche.

- Top Hammer: Generally uses lighter, more mobile rigs that are quicker to set up and move between drilling locations. This makes it ideal for sites with frequent relocations or restricted access.

Environmental Considerations (Noise):

- DTH: Typically produces less surface noise as the percussive action occurs downhole, muffling the sound. This is an advantage in urban areas or environmentally sensitive sites with strict noise regulations.

- Top Hammer: Generates more significant surface noise due to the exposed hammering mechanism. Noise reduction measures might be necessary in populated areas, impacting operational flexibility.

Conclusion

In conclusion, both DTH and Top Hammer drilling methods offer distinct advantages, making them suitable for different applications. DTH excels in deeper holes and harder rock formations due to its efficient energy transfer at the bit, leading to straighter holes and often faster penetration in challenging conditions. Top Hammer, on the other hand, provides versatility and control, particularly in smaller diameter holes and varied ground conditions, often favored for its mobility and ease of use in diverse surface applications.

Choosing between DTH and Top Hammer ultimately depends on your project’s specific requirements, including geological conditions, hole depth, required diameter, and overall budget. Understanding their fundamental operational differences in energy transmission and hole cleaning is key to selecting the most efficient and cost-effective drilling solution for your needs.

For reliable and high-performance DTH hammers, consider Sinodrills. As a trusted manufacturer, Sinodrills offers a wide range of wholesale DTH hammers designed for durability and efficiency across various drilling applications. Partner with Sinodrills for your DTH drilling needs and optimize your project’s productivity.