Top Hammer drilling stands as a foundational method in rock excavation, widely employed across construction, mining, and quarrying. Understanding its mechanics and the specific tools required is crucial for optimizing efficiency and achieving desired project outcomes in various surface drilling applications.

This guide will delve into the intricacies of Top Hammer drilling, explaining its operational principles and highlighting the essential drilling tools that complement this powerful technique. From drill bits to rods and shanks, we will cover what’s needed for successful and efficient rock penetration.

What is Top Hammer Drilling?

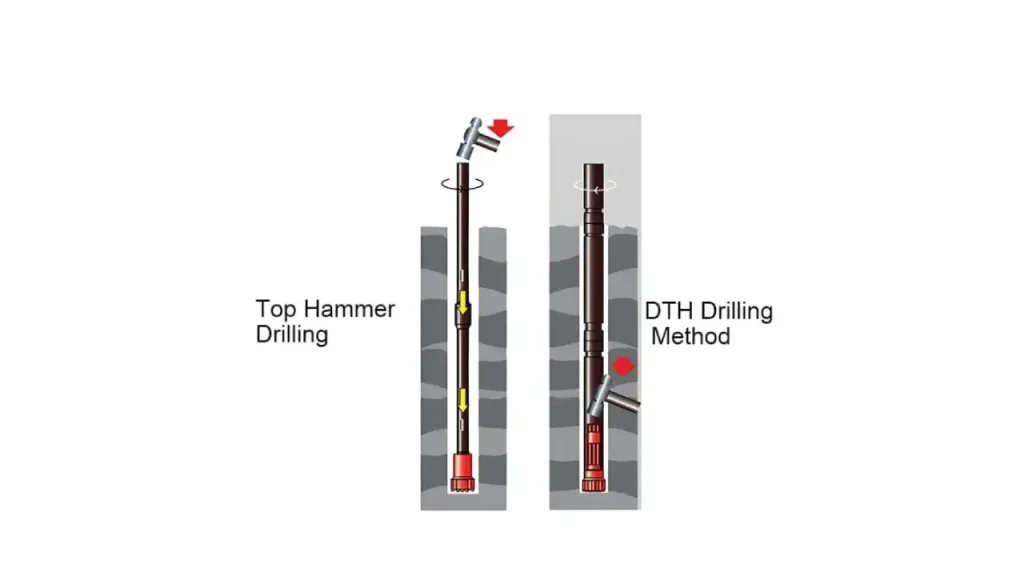

Top hammer drilling is a percussive drilling method where the hammer mechanism is located at the top of the drill string, on the surface drill rig. The impact energy generated by this surface-mounted hammer is transmitted down through the drill rods, via their threaded connections, to the drill bit at the bottom of the hole.

This method combines both rotation and percussion to break rock and is commonly used for smaller diameter holes in a wide range of applications, including construction, quarrying, and road building, where its versatility and mobility are advantageous.

Top Hammer Drilling Tools

Top Hammer drilling relies on a specialized set of tools designed to efficiently transmit impact energy from the surface drill rig to the rock face. These tools work in unison to perform the percussive and rotational actions necessary for breaking rock. The quality and compatibility of these components are crucial for maximizing drilling productivity and ensuring tool longevity in various demanding applications.

The essential tools in a Top Hammer drilling setup typically include:

- Drill Bits: These are the cutting ends that directly interact with the rock. They come in various designs (e.g., button, cross, chisel) and carbide configurations, selected based on rock hardness and desired hole characteristics.

- Drill Rods: These threaded steel tubes transmit the impact energy and rotational torque from the drill rig to the bit. They come in different lengths and diameters, with varying thread types (e.g., R-thread, T-thread, GT-thread) to suit specific drilling needs.

- Shanks Adapters (Striking Bars): Located at the top of the drill string, these components connect the drill rig’s hydraulic drifter to the first drill rod. They are precisely machined to absorb and transfer the powerful percussive blows effectively.

- Coupling Sleeves: These threaded connectors join drill rods together, ensuring secure and strong connections that can withstand the significant forces involved in top hammer drilling. They are designed to maintain thread integrity under repeated impacts.

Advantages of Top Hammer Drilling Tool

Top Hammer drilling tools offer several distinct advantages that make them valuable in various drilling applications. Their design focuses on delivering efficient percussive power from the surface, contributing to their overall effectiveness and operational benefits.

Key advantages include:

- High drilling speed and efficiency: Top hammer tools are recognized for their ability to drill holes rapidly and accurately. Their impact mechanism ensures quick penetration, while the drill string’s rotation helps maintain a straight bore, reducing overall operational time and costs.

- Suitable for hard rock drilling: These tools are highly effective in breaking through hard rock formations. The powerful impact force generated by the hammer efficiently fractures the rock surface, allowing for deeper penetration and making them ideal for challenging mining and construction projects.

- Low maintenance and downtime: Engineered for durability and reliability, top hammer drilling tools require minimal maintenance. Their robust construction and design with easily replaceable wear parts contribute to reduced downtime, significantly increasing overall productivity and extending the tool’s lifespan.

- Versatility: Top hammer drilling tools are exceptionally versatile, adaptable to a wide array of drilling applications. They are commonly used for tasks such as drilling blast holes, anchor holes, and exploration drilling, making them an invaluable asset across the mining and construction industries.

Difference Between DTH Drilling and Top Hammer Drilling

Understanding the fundamental operational differences between DTH (Down-The-Hole) and Top Hammer drilling methods is crucial for optimizing project efficiency. This comparison delves into their distinct mechanics, suitability for various conditions, and overall performance characteristics, guiding optimal equipment selection.

Energy Transfer Mechanism

In DTH drilling, the percussive hammer is located directly at the bottom of the borehole, striking the drill bit from within. Compressed air powers a piston inside the hammer, transmitting energy directly to the rock. This direct impact minimizes energy loss as depth increases, ensuring consistent power for efficient rock breaking.

Hole Straightness

DTH hammers are renowned for their ability to produce exceptionally straight holes, even in challenging and variable rock formations. The hammer’s position at the bottom of the hole acts as a natural stabilizer, guiding the bit and minimizing deviation. This precision is critical for applications requiring strict borehole alignment, such as foundation work.

Depth Capability

DTH drilling is the preferred method for deep holes, often exceeding hundreds of meters. The direct impact mechanism ensures that the effectiveness of the percussive action is maintained regardless of the depth. This makes DTH highly efficient for large-scale mining, deep water wells, and extensive geotechnical investigations.

Bit Wear and Longevity

DTH drilling generally results in longer drill bit life, especially in very hard and abrasive rock. The efficient flushing system, coupled with the direct and consistent impact, reduces the risk of regrinding cuttings. This minimizes wear on carbide inserts, leading to extended service intervals and lower consumable costs.

Noise and Vibration

DTH hammers typically produce lower noise levels at the surface. Since the primary percussive action occurs deep within the borehole, much of the sound is absorbed and muffled by the surrounding rock and overburden. This makes DTH a more environmentally friendly option for noise-sensitive areas or urban projects.

Application Focus

DTH drilling excels in applications requiring high penetration rates in very hard, competent rock, and where large-diameter, straight holes are critical. Its primary focus is on maximizing drilling efficiency and achieving precise boreholes in challenging geological conditions, making it ideal for deep mining and large construction.

| Aspect | DTH Drilling | Top Hammer Drilling |

| Energy Transfer | Direct (hammer at hole bottom) | Indirect (hammer at surface, via rods) |

| Hole Straightness | Excellent, inherent guidance | Good, can be prone to deviation |

| Depth Capability | Ideal for deep holes (consistent efficiency) | Suited for shallower to moderate depths |

| Bit Wear & Longevity | Generally longer bit life, less regrinding | Can be faster bit wear, more abrasive action |

| Noise & Vibration | Lower surface noise (muffled by ground) | Higher surface noise and vibration |

| Application Focus | Hard rock, deep, straight, large holes | Varied rock, shallower, mobile, small-medium holes |

Conclusion

In conclusion, Top Hammer drilling remains a highly versatile and efficient method for a wide range of surface rock excavation projects. Its distinct mechanism, delivering impact energy from the surface, makes it particularly well-suited for shallower depths, varying ground conditions, and applications prioritizing mobility and rapid setup. Understanding its operational nuances is key to maximizing productivity.

The success of any Top Hammer drilling operation heavily relies on selecting the appropriate tools. From robust drill bits designed for specific rock types to high-quality drill rods and shanks, each component plays a critical role in optimizing penetration rates, ensuring hole straightness, and extending overall tool life, directly impacting project profitability.

For reliable and high-performance Top Hammer drilling tools, consider Sinodrills. As a leading manufacturer, Sinodrills offers a comprehensive range of wholesale Top Hammer drilling tools, including bits, rods, and shanks, engineered for durability and efficiency. Partner with Sinodrills to equip your projects with dependable solutions.