In the demanding world of drilling, the quality and selection of your drill pipe are paramount to operational success. With various types and specifications available, understanding drill pipe classification becomes crucial for optimizing performance and ensuring safety. This blog post will delve into how the American Petroleum Institute (API) standards provide a comprehensive framework for classifying drill pipe.

Decoding API standards is key to selecting the right drill pipe for your specific project needs. These guidelines ensure that drill pipes meet stringent requirements for material grades, dimensions, mechanical properties, and inspection, ultimately enhancing efficiency and minimizing risks in your drilling operations.

What is Drill Pipe Classification

Recommended Drill Pipes

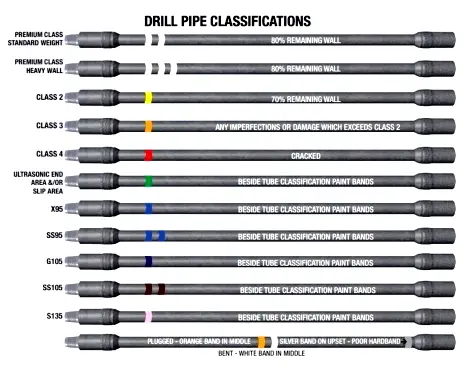

Drill pipe classification is a system used to categorize drill pipe based on its condition, material properties, dimensions, and intended use, primarily governed by industry standards like those from the American Petroleum Institute (API).

This classification ensures that drill pipes meet specific performance criteria for strength, wear resistance, and fatigue life, which are critical for safe and efficient drilling operations. It helps operators select the appropriate pipe for various well designs, depths, and geological formations, considering factors like remaining wall thickness for used pipes, steel grade (e.g., E75, X95, G105, S135), and physical dimensions like length range and diameter.

Drill Pipe Classification

Drill pipe classification is essential for ensuring the safety and efficiency of drilling operations. It categorizes pipes based on their physical condition, material strength, and intended application. This system allows operators to quickly identify the suitability and remaining useful life of each drill pipe, optimizing their use in the drill string.

Premium Class Standard Weight

Premium Class Standard Weight drill pipe, as shown in the image, indicates a used pipe that retains at least 80% of its original wall thickness. This classification signifies that while the pipe has been in service, it is still in excellent condition and capable of handling significant operational demands. It is a cost-effective alternative to new pipes, widely used for its reliability and durability in various drilling environments.

Premium Class Heavy Weight

Similar to the Standard Weight, Premium Class Heavy Weight drill pipe also retains 80% of its remaining wall. However, this type features thicker walls and a heavier weight per foot compared to standard pipes. This increased robustness makes it particularly suitable for demanding applications, providing additional stiffness and weight to the drill string, which is crucial for maintaining drilling accuracy and stability, especially in directional drilling.

Class 2

Class 2 drill pipe indicates a used pipe with at least 70% of its original wall thickness remaining. While still functional, pipes in this class have experienced more wear than Premium Class. They are typically used in less demanding drilling applications where the operational stresses are not as severe, offering a more economical option for projects with less stringent requirements for pipe integrity.

Class 3

Class 3 drill pipe is characterized by imperfections or damage that exceed the criteria for Class 2, including potentially significant wear or minor defects. These pipes have a reduced remaining wall thickness, making them suitable for very light duty applications or for repurposing outside of critical drilling operations. Their use in active drilling is generally limited to scenarios with minimal stress to avoid failure.

Class 4

Class 4 drill pipe is identified by the presence of cracks, indicating substantial structural compromise. This classification signifies that the pipe is unsafe for any drilling operations due to the high risk of failure under stress. Pipes in Class 4 are typically retired from drilling service and are often designated for scrap or repurposing for non-structural applications where integrity is not a concern.

Ultrasonic End Area & Slip Area

This classification refers to pipes that have undergone inspection in the ultrasonic end and slip areas, which are critical zones prone to damage from repeated handling and stress. The image indicates that these pipes have paint bands beside the tube classification bands, confirming that these specific high-stress areas have been thoroughly checked for defects such as fatigue cracks or significant wear that might compromise the pipe’s integrity during operations.

X95

X95 is a material grade for drill pipe, signifying a minimum yield strength of 95,000 PSI. As shown by its specific paint band, X95 pipes are designed for moderate to high-stress drilling applications, offering enhanced strength compared to lower grades. This grade is often chosen for its balance of strength and ductility, making it suitable for a wide range of drilling conditions where higher performance than standard grades is required.

S135

S135 is the highest strength API drill pipe grade, with a minimum yield strength of 135,000 PSI. Identified by its distinct pink paint band, S135 pipes are engineered for the most demanding drilling environments, including ultra-deep wells and high-pressure, high-temperature (HPHT) conditions. Their superior strength and toughness provide exceptional resistance to fatigue and stress, crucial for maintaining drill string integrity in challenging operations.

Types of Drill Pipes

Understanding the various types of drill pipes is crucial for efficient and safe drilling operations. Each type is designed with specific characteristics to meet the diverse demands of different drilling environments, depths, and well trajectories. Selecting the appropriate drill pipe ensures optimal performance and minimizes risks.

Standard Drill Pipe

Standard drill pipe is the most common type, characterized by a uniform wall thickness along its body, with thicker upset areas at the ends where tool joints are attached. It is primarily designed to transmit torque and weight from the surface rig to the drill bit, while also serving as a conduit for drilling fluid. Available in various API grades (e.g., E75, X95, G105, S135), it forms the bulk of the drill string in most conventional drilling operations.

Heavy Weight Drill Pipe (HWDP)

Heavy Weight Drill Pipe (HWDP) features a larger wall thickness and often has wear pads or centralizers along its body, making it heavier and more rigid than standard drill pipe but lighter than drill collars. HWDP is commonly placed in the transition zone between the stiff drill collars and the more flexible standard drill pipe. It helps to provide additional weight on bit, reduce fatigue failures in the transition zone, and improve directional control in deviated wells by adding stiffness.

Drill Collars

Drill collars are thick-walled, heavy-duty pipes that provide the necessary weight on the drill bit to achieve optimal penetration rates. They are placed directly above the drill bit in the bottom hole assembly (BHA) and are designed to keep the drill string in tension, preventing buckling and improving drilling efficiency. Drill collars are typically non-magnetic for MWD/LWD tools and come in various sizes and configurations depending on the well’s specific requirements.

Kelly

A Kelly is a heavy, square or hexagonal shaped steel pipe that fits into a corresponding shape in the rotary table or top drive. It is the topmost section of the drill string, providing the means to transmit rotary motion from the surface equipment to the rest of the drill string. As drilling progresses, the Kelly moves downward through the rotary table, allowing continuous rotation and downward movement of the drill string. While still used in some older rigs, top drives have largely replaced Kelly systems.

Pup Joints

Pup joints are short lengths of drill pipe, ranging from 5 to 20 feet, used to adjust the overall length of the drill string to enable specific operations, such as spacing out the drill string for tool placement or achieving precise depths. They are manufactured to the same specifications as standard drill pipe regarding grade and diameter, ensuring seamless integration within the drill string while offering flexibility for length adjustments.

How to Choose Suitable Drill Pipes?

Choosing the suitable drill pipe is a critical decision that directly impacts the success, safety, and cost-effectiveness of any drilling operation. It’s not a one-size-fits-all solution; rather, it requires a careful assessment of various factors related to the well’s design, the geological environment, and the specific demands of the drilling process.

An incorrect choice can lead to premature pipe failure, costly non-productive time, and potential safety hazards. Therefore, a systematic approach to selection is essential to optimize performance and ensure the longevity of your drill string.

The selection process involves balancing the mechanical properties of the pipe with the anticipated stresses and conditions downhole. This means considering not only the initial purchase cost but also the long-term operational efficiency, maintenance requirements, and the potential for costly repairs or replacements.

By making an informed decision, operators can significantly enhance drilling efficiency, improve safety, and achieve greater economic returns on their projects.

- Well Design and Depth: Consider the total depth of the well, the diameter of the borehole, and the trajectory (vertical, highly deviated, horizontal). Deeper and more complex wells generally require higher strength grades and larger diameter pipes to manage increased loads and pressures. The length range of the drill pipe (e.g., Range 2 or Range 3) is also determined by rig height and operational preferences to minimize connections.

- Geological Formations and Environment: The type of rock or soil being drilled through is crucial. Abrasive formations necessitate pipes with superior wear resistance, often enhanced with hardbanding on tool joints. Corrosive environments (e.g., those containing H2S, CO2, or chlorides) demand specialized steel grades (e.g., sour service grades) to prevent embrittlement and cracking. High-temperature and high-pressure (HTHP) conditions also require pipes with specific material properties capable of maintaining strength and integrity under extreme thermal and pressure loads.

- Drilling Method and Rig Capabilities: The chosen drilling method (e.g., conventional rotary, directional drilling with mud motors, coiled tubing drilling) influences pipe selection. The capabilities of the drilling rig, including its hoisting capacity, rotary torque, and pump pressure, must be matched with the drill pipe’s specifications. The pipe’s outer diameter, inner diameter, and tool joint size must be compatible with the rig’s equipment, the bottom hole assembly (BHA), and the wellbore design to ensure efficient drilling fluid circulation and proper clearance.

- Load and Stress Requirements: Evaluate the maximum anticipated tensile, compressive, torsional, and bending stresses the drill pipe will experience. This includes weight on bit (WOB), drag, torque, and shock loads. The selected pipe’s yield strength, tensile strength, and fatigue resistance must be adequate to safely withstand these dynamic forces throughout the drilling operation and during tripping in/out of the hole. For highly deviated or horizontal wells, higher torsional capacity and bending resistance are particularly important.

- Pipe Condition and Inspection Standards (for used pipe): When considering used drill pipe, its classification (e.g., Premium Class, Class 2) based on remaining wall thickness, presence of defects, and inspection results is paramount. Adherence to standards like API RP 7G or DS-1 (Drill String Design and Operations) for inspection criteria ensures that used pipes meet minimum safety and performance requirements. Regular and thorough inspection is crucial for maximizing the safe lifespan of the drill string.

- Cost and Lifespan (Total Cost of Ownership): While the initial purchase price is a factor, consider the total cost of ownership. Higher quality drill pipes or those with premium features (like specialized hardbanding or corrosion-resistant coatings) may have a higher upfront cost but can offer significantly extended lifespan, reduced non-productive time due to fewer failures, and lower overall maintenance and replacement expenses. Balance initial investment with long-term operational efficiency and reliability.

Conclusion

Understanding drill pipe classification, particularly through the lens of API standards, empowers you to make informed decisions that directly impact your drilling project’s success. By carefully considering material grades, dimensions, and performance benchmarks, you ensure a drill string that is not only robust and reliable but also perfectly suited to the unique demands of your downhole environment.

This meticulous selection process, guided by API specifications, leads to enhanced drilling efficiency, reduced operational risks, and ultimately, a more cost-effective and successful venture. The integrity of your drill string is the backbone of your operation, and choosing the right components is non-negotiable for achieving peak performance and maximizing uptime.

For API-compliant drill pipes that you can trust, look no further than Sinodrills. We offer a comprehensive range of wholesale drill pipes, meticulously manufactured to meet stringent industry standards. Contact Sinodrills today to secure the reliable drill pipes your project deserves.