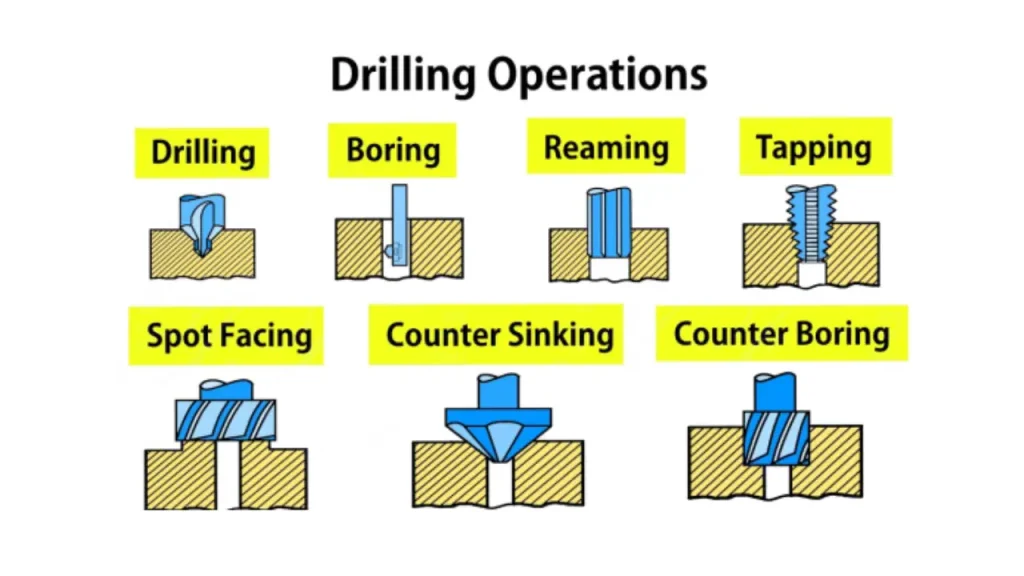

In the world of precision manufacturing and construction, creating a hole is often just the first step. While drilling forms the initial bore, achieving exact dimensions, superior surface finish, and true roundness requires an additional, crucial process: reaming.

This guide will delve into what reaming entails in drilling operations, explaining its purpose, how it differs from simple drilling, and why it’s indispensable for applications demanding high-quality, precise holes.

What is Reaming in Drilling?

In drilling, reaming is a precision finishing process that follows the initial creation of a hole by a drill bit or coring.

Its primary purpose is not to create a new hole, but to enlarge, true, and smooth an existing one to very accurate dimensions and a superior surface finish. This is particularly crucial in applications like horizontal directional drilling (HDD) for rock, where the final bore must meet strict specifications for pipeline installation.

Key aspects of reaming in drilling include:

- Precision Enlargement: Reaming removes only a minimal amount of material from the walls of a pre-drilled hole, bringing it to a highly exact and consistent final diameter.

- Improved Hole Quality: It significantly enhances the roundness, straightness, and concentricity of the bore, correcting any inaccuracies left by the initial drilling process.

- Smoother Surface Finish: The multiple cutting edges of a reamer shave the bore walls, resulting in a much smoother internal surface compared to a drilled hole.

- Application in Rock Drilling: For HDD in rock, reaming involves specialized rock reamers that progressively enlarge the pilot bore to the required size, creating a stable and clean pathway for product installation.

- Preparation for Installation: A reamed hole ensures a proper fit for components like pipes, bearings, or pins, minimizing friction and potential damage during installation and throughout the product’s lifespan.

What is a Reamer Drill Bit Used For?

While a “reamer drill bit” might sometimes be used loosely to describe a tool that combines aspects of both, it’s crucial to understand their distinct primary functions in the industry of professional rock drilling.

A drill bit is engineered for the initial act of creating a hole, breaking through solid rock formations to establish a pilot bore or the full production hole. It prioritizes aggressive material removal and penetration rate, using designs like tricone cutters or PDC elements to crush, cut, or abrade the rock.

A reamer, particularly an HDD rock reamer, is then used in a subsequent operation. Its purpose is not to start a new hole but to enlarge and refine an existing one to a precise diameter and achieve a smoother, more stable bore wall. This is vital for installing pipelines or conduits where accurate sizing and a clean path are critical for successful pull-back and long-term integrity.

Therefore, while both tools create or expand holes, their applications are sequential and focused on different aspects of the hole-making process.

Here’s what each is used for:

What is a Drill Bit Used For in Rock Drilling?

- Creating Pilot Holes: Drill bits are fundamental for boring the initial, smaller diameter hole that establishes the trajectory and path for the entire project. This is the first step in most directional drilling operations.

- Production Drilling: In some cases, drill bits are used to create the final production hole directly, especially in conventional vertical drilling or when the final hole tolerance is less critical.

- Geological Exploration: Drill bits are used to extract core samples or cuttings to understand the subsurface geology and plan subsequent drilling and reaming operations.

- Setting Casing: Drill bits can also be integral to operations that involve drilling and setting initial casing strings in unstable formations.

What a Reamer is Used For (in Rock Drilling, specifically HDD Rock Reamers):

- Hole Enlargement (Reaming): The primary use of an HDD rock reamer is to systematically enlarge a previously drilled pilot bore to the desired final diameter, ready for the product pipeline or conduit. This often involves multiple passes with progressively larger reamers.

- Borehole Stabilization: As reamers enlarge the hole, they also help to condition and stabilize the bore walls, removing irregularities and creating a smoother, more consistent path for the product.

- Efficient Cuttings Management: Reamers are designed to facilitate the efficient flow and removal of rock cuttings by the drilling fluid, preventing blockages and ensuring a clean bore.

- Facilitating Product Pull-Back: By creating a precisely sized and clean bore, reamers significantly reduce friction and resistance during the critical phase of pulling the product pipe through the enlarged hole.

Difference Between Drilling and Reaming

Understanding the distinction between drilling and reaming is vital, as they are used for completely different purposes in the hole-making sequence. Drilling is the initial, rapid process of removing bulk material, while reaming is the final, slow finishing pass for ultimate precision.

| Feature | Drilling | Reaming |

| Primary Goal | Create a hole. | Refine an existing hole. |

| Material Removal | High Rate. | Low Rate. |

| Precision & Finish | Low/Moderate. | High/Excellent. |

1. Primary Purpose and Sequence

- Drilling (Creation): This is always the first step. The goal is to quickly penetrate the material and establish the initial bore path and diameter. Drills are designed for aggressive material removal from solid stock, achieving moderate but not high-precision tolerances for a hole.

- Reaming (Refinement): Reaming is a secondary, finishing process that must follow a pre-drilled pilot hole. Its singular purpose is to enlarge the hole by a tiny amount, correct minor imperfections, and prepare the bore for casing or a precise fit.

2. Material Removal and Tool Design

- Drilling (Bulk Removal): Drill bits feature typically two cutting edges designed to remove a large volume of material quickly. This high removal rate generates a relatively rough surface and leaves a less-than-perfectly cylindrical hole, which is acceptable for general applications.

- Reaming (Fine Shaving): Reamers use a multi-edged design and a scraping action to remove only a few thousandths of an inch of material. This low-speed, multi-point process is specifically engineered to smooth the walls and produce an extremely accurate diameter and superior surface finish.

3. Precision and Tolerance

- Drilling (Lower Precision): Due to the high cutting forces and tool flexibility, drilled holes generally hold wide tolerances, and the surface finish is fair. This is sufficient for holes that do not require an exact fit, like standard bolt holes.

- Reaming (Highest Precision): Reaming is employed when tight tolerances are critical. It provides a roundness and surface quality essential for high-performance applications like dowel-pin press fits or securing downhole equipment in a wellbore.

How to Use a Reamer Drill?

Using a reamer in rock drilling, particularly an HDD rock reamer, is a multi-step process crucial for enlarging and finishing a bore after the initial pilot hole has been drilled. Proper technique ensures efficiency and a high-quality finished bore.

This guide outlines the key steps involved in effectively using a reamer for rock drilling applications, ensuring successful pipeline or conduit installation.

Step 1: Pre-Drill Pilot Hole

Before reaming, an initial pilot hole must be drilled along the precise path. This smaller diameter hole establishes the exact trajectory and removes the bulk of the rock, creating a guide for the subsequent reaming operation. The pilot hole ensures the reamer follows the intended design.

The pilot hole’s accuracy is critical, as any deviation here will affect the final reamed bore. The drill bit used for this step is selected based on the rock type and required penetration rate, focusing on establishing the initial path efficiently.

Step 2: Select the Correct Reamer

Choosing the appropriate reamer is paramount. This involves matching the reamer’s type (e.g., roller cone, fixed blade) and cutter configuration to the specific rock formation’s hardness and abrasiveness. The desired final bore diameter also dictates the reamer’s size.

Consider the product pipe’s outer diameter; the reamer’s size should provide adequate annular space for fluid flow and pullback. Incorrect reamer selection can lead to excessive wear, reduced efficiency, or an improperly sized bore.

Step 3: Attach Reamer to Drill String

Once selected, the reamer is securely attached to the drill string. This connection is typically made at the exit side of the pilot hole (for pullback reaming). Ensure all threads are clean and properly torqued according to the rock reamer manufacturer’s specifications to prevent disconnection during operation.

A secure connection is vital for safety and operational efficiency. Any weakness in the connection can lead to tool loss downhole or catastrophic failure, causing significant project delays and costs.

Step 4: Initiate Reaming Operations

Begin rotating the drill string while simultaneously applying pullback force. The reamer’s cutting structures engage the rock at the pilot hole’s circumference, progressively enlarging the bore. Maintain a consistent rotational speed (RPM) and pullback rate.

Pumping drilling fluid is crucial during this step. The fluid cools the reamer, lubricates the bore, and most importantly, carries the rock cuttings back to the surface, keeping the hole clean and preventing blockages.

Step 5: Monitor and Adjust

Continuously monitor drilling parameters such as torque, pullback pressure, drilling fluid pressure, and penetration rate. These readings provide real-time feedback on the reamer’s performance and rock conditions.

Adjust RPM, pullback speed, and fluid flow as needed to optimize performance and prevent overloading the rig or reamer. If significant changes in rock type are encountered, parameters may need fine-tuning for efficiency.

Step 6: Multiple Passes (if necessary)

For very large diameter bores or extremely hard rock, it may be necessary to perform multiple reaming passes. This involves using progressively larger reamers, each enlarging the bore in stages until the final desired diameter is achieved.

Staging the reaming process reduces stress on the equipment and allows for more controlled enlargement. It also improves bore stability by gradually expanding the tunnel, minimizing the risk of collapse.

Reamer vs Drill Bit

In the field of oil and gas drilling, drill bits and reamers are two distinct tools with different functions. While both are used to shape the wellbore, a drill bit is used to create the initial hole, whereas a reamer is used to enlarge or smooth an existing hole to the desired diameter.

Primary Function

A drill bit’s primary function is to break and penetrate new rock formations to create a borehole. It is the leading tool on the bottom of the drill string and is responsible for all new hole excavation. Its design is focused on maximum penetration rate and efficiency in cutting new rock.

Cutting Action

Drill bits use a variety of cutting actions, including crushing, scraping, shearing, and grinding, to break apart virgin rock. The specific action depends on the bit type, such as the rolling and crushing action of a roller cone bit or the shearing action of a fixed-cutter bit. A reamer, on the other hand, works by scraping or “reaming” the sides of an existing wellbore to smooth and enlarge it to a specific diameter.

Location in the Drill String

A drill bit is always located at the very end of the drill string, at the bottom of the hole. It is the first tool to make contact with the new formation. A reamer is typically placed above the drill bit in the bottom-hole assembly (BHA), where it follows the drill bit’s path.

Purpose

The purpose of a drill bit is to advance the wellbore forward, either vertically, horizontally, or directionally. The purpose of a reamer is to ensure the wellbore’s diameter is uniform and to remove any irregularities, ledges, or restrictions that could cause issues with future operations like running casing or other tools. It ensures the wellbore’s integrity.

Design

Drill bits are designed with a variety of cutting structures and profiles optimized for different rock types and drilling objectives. Their design is focused on generating a high rate of penetration. Reamers have cutting blades or rollers on their outer body, and their design is centered on providing a precise, uniform diameter for the wellbore and ensuring stability for the drilling assembly.

| Aspect | Drill Bit | Reamer |

| Primary Function | To create a new borehole | To enlarge and smooth an existing hole |

| Cutting Action | Crushing, shearing, grinding virgin rock | Scraping or smoothing the wellbore walls |

| Location | At the very bottom of the drill string | Typically placed above the drill bit |

| Purpose | To advance the wellbore forward | To ensure wellbore diameter and integrity |

| Design | Optimized for high penetration rate | Optimized for wellbore stability and precise diameter |

How to Choose Suitable Reaming Drill Bits?

Choosing a suitable reaming drill bit is a critical decision that depends on several factors to ensure an efficient and successful drilling operation. The process involves a careful analysis of the wellbore’s geological conditions, the required hole size, and the desired outcome. The goal is to select a bit that will not only effectively enlarge the hole but also maintain stability and prevent damage to the drill string.

Here are the key factors to consider when choosing a reaming drill bit:

- Formation Hardness and Abrasiveness: The bit’s cutting structure must match the rock type. For soft formations like shale, a bit with long, widely spaced cutters is ideal. For hard, abrasive formations, bits with more durable, closely spaced cutters made of tungsten carbide or diamond are preferred to prevent premature wear.

- Hole Size and Profile: The reamer must be sized precisely to the final wellbore diameter you need. Additionally, the reamer’s profile—the shape of its cutters and body—must be designed to ream the specific type of wellbore geometry, whether it’s a straight hole or a complex, curved path.

- Directional Drilling Requirements: If you are reaming a directional or horizontal well, you need a reamer that can handle the increased torque and side forces. Some reamers are specifically designed with stabilization features to maintain the wellbore’s trajectory and prevent a “spiral” hole.

- Fluid Circulation and Cuttings Removal: The reamer’s hydraulics, including the number and placement of its nozzles, are crucial for effective cuttings removal. Poor cleaning can lead to cuttings building up around the bit, which can increase torque, cause a loss of circulation, and damage the bit.

- Connection and Compatibility: The reamer must have a compatible connection to fit securely with the rest of the bottom hole assembly (BHA) and the drill string. It’s essential to ensure the reamer’s size and specifications are a good match for the drill bit it’s following.

Conclusion

In essence, reaming transforms a basic drilled hole into a precise bore. It’s a critical finishing step that ensures proper sizing, superior surface finish, and improved roundness, indispensable for applications demanding tight tolerances and reliable performance, especially in challenging rock formations.

Understanding the distinct role of reaming versus initial drilling is vital for successful project execution and maximizing the longevity of installed components. This process significantly contributes to the overall integrity and efficiency of your drilling operations.

For all your rock drilling needs, including top-quality wholesale rock reamer tools designed for durability and precision, look no further than Sinodrills. Based in Qingdao, Shandong, China, we are your trusted partner for robust drilling solutions.