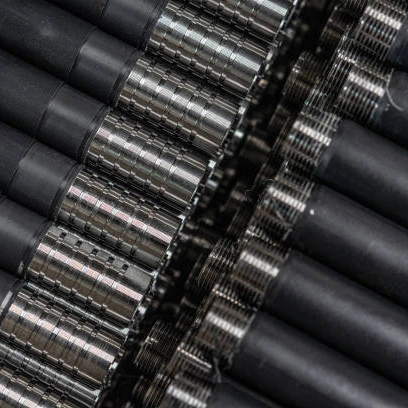

Custom Wireline Drill Rods Manufacturer in China

Wireline drill rods are key components in mineral exploration and geotechnical drilling. They connect drilling tools and transmit torque and axial force, enabling efficient rock penetration. Made of high-strength alloy steel, they resist wear and corrosion. Their hollow design allows wireline tools to pass through, simplifying rod retrieval. Vital for deep drilling, they boost efficiency and reduce downtime, widely used in mining, oil, and construction.

Sinodrills - Your Trusted Wireline Drill Rods Manufacturer from China

Various Wireline Drill Rods

wire line drilling rods

Wire line drilling rods form the core of any wireline drilling system, uniquely enabling continuous coring operations. These specialized drill rods facilitate the quick recovery and deployment of the core barrel through their central channel, thereby avoiding the time-consuming tripping process common in conventional drilling. For exploration projects aiming to maximize drilling speed and reduce operational costs, optimizing the selection of wire line drilling rods is paramount, as they directly impact hole quality and on-site productivity.

standard wireline drill rod

The standard wireline drill rod is the most widely utilized type in wireline drilling, providing a reliable foundation for diverse geological exploration projects. Typically manufactured from high-strength steel, they ensure durability and stability across various geological formations. The design of these drill rods strikes a balance between weight, strength, and flexibility, suitable for routine coring operations. Selecting the appropriate standard wireline drill rod is essential for achieving efficient, cost-effective drilling operations and obtaining high-quality core samples.

lite wireline drill rods

Lite wireline drill rods are specifically engineered for scenarios requiring reduced drill string weight or drilling in hard-to-access areas. They often feature lighter materials or optimized designs to decrease the overall weight of the drill string, thereby lessening the demands on drilling rig hoisting capabilities and improving transport convenience. Despite their lighter weight, lite wireline drill rods maintain the necessary strength and rigidity to ensure efficient wireline coring and excellent drilling performance in specialized applications like mountainous or remote regions.

drilling wire line drill rods

Drilling wire line drill rods are critical components within the wireline drilling method used for creating and maintaining the borehole. These hollow drill rods facilitate the operation of the core barrel through their central bore, enabling continuous core collection. They must possess exceptional torsional strength and tensile strength to withstand the immense stresses encountered during the drilling process. The correct selection and maintenance of drilling wire line drill rods are essential for ensuring borehole depth, hole consistency, and overall drilling efficiency.

deep hole wireline drill rod

The deep hole wireline drill rod is specifically designed to meet the rigorous demands of deep hole drilling. These drill rods are constructed from advanced alloy steels and undergo special heat treatments to provide superior strength, rigidity, and fatigue resistance, enabling them to withstand immense pressures and stresses encountered in deep geological formations. Their connection threads are also optimized to ensure reliability during extended, high-load deep hole coring operations. Selecting high-quality deep hole wireline drill rods is crucial for the successful completion of challenging deep exploration projects.

-

Self Drilling Anchor Spherical Nuts

Read more -

Self Drilling Anchor Couplers

Read more -

3 Wings Step Drag Bits

Read more -

DTH Adapter BOX to PIN

Read more -

Self Drilling Anchor Centralizers

Read more -

Self Drilling Anchor Adapters

Read more -

Self Drilling Anchor Plates

Read more -

Self Drilling Anchor Hexagonal Nuts

Read more -

Self Drilling Anchor Bits

Read more -

R Thread Self Drilling Anchor Bars

Read more -

T Thread Self Drilling Anchor Bars

Read more -

R25 Self-Drilling Anchor Systems

Read more

Customize Your Desired Wireline Drill Rods

Material of Wireline Drill Rods

Wireline drill rods are typically made of high-grade alloy steel. This material offers exceptional tensile strength and toughness, crucial for withstanding the high torque and pressure in drilling. It also provides good corrosion resistance, ensuring longevity in harsh underground environments, making the rods reliable for long-term use.

Structure of Wireline Drill Rods

The structure of wireline drill rods features a hollow core, and a key design. This allows wireline tools to pass through, facilitating easy rod and tool retrieval. The ends have threaded connections for secure linking, ensuring stable power transmission and efficient operation during drilling processes.

Functions of Wireline Drill Rods

Wireline drill rods have core functions: transmitting torque from the drill to the bit for rock breaking, and transferring axial force for penetration. Their hollow design enables quick tool changes, reducing non-drilling time. They also help maintain borehole stability, ensuring smooth and efficient drilling operations.

Applications of Wireline Drill Rods

Wireline drill rods are widely used in mining exploration for ore deposit detection. They’re essential in oil and gas drilling for well construction. In geotechnical engineering, they aid in soil and rock sampling. Their efficiency makes them vital in these fields, boosting project progress.

What is the difference between conventional drilling and wireline drilling?

Conventional drilling requires the entire drill string to be repeatedly removed from the wellbore (a process called “tripping”) whenever a core sample needs to be retrieved or the drill bit needs to be changed. This method leads to significant non-productive time, increasing operational costs and slowing down the overall drilling progress. It’s a less efficient approach, particularly in deep or challenging wells where frequent tripping can be very time-consuming.

In contrast, wireline drilling offers a much more streamlined process. With this method, a specialized core barrel is lowered and retrieved through the drill string using a wireline cable, eliminating the need to pull the entire string out of the hole. This key difference drastically reduces downtime, improves drilling efficiency, and makes wireline drilling a preferred choice for geological exploration, especially in deep holes or remote areas where minimizing operational interruptions is crucial.

What are the different types of drill rods?

Drill rods, often referred to as drill pipes in the oil and gas industry, are essential hollow steel tubes that transmit torque and drilling fluid to the drill bit. They are engineered to withstand extreme stresses, including torsional, tensile, and compressive forces encountered during drilling. Common classifications include Standard Drill Rods for general applications, and Heavy Weight Drill Pipe (HWDP), which acts as a transitional component within the Bottom Hole Assembly (BHA) to provide stiffness and prevent buckling.

Another critical type is Drill Collars, which are thicker, heavier pipes specifically designed to provide the necessary weight on bit (WOB) for effective rock cutting. Beyond these, specialized drill rods exist with enhanced material properties or unique connections, tailored for demanding conditions like directional drilling or high-pressure/high-temperature (HPHT) environments, ensuring optimal performance and maintaining wellbore integrity.

What is the difference between wireline depth and drill depth?

Wireline depth refers to the measurement of the position of a wireline tool within the wellbore, typically recorded from a defined surface reference point, such as the rotary table or kelly bushing. This measurement is crucial for various well interventions, including logging, perforating, and other diagnostic or completion activities, providing precise location data for downhole operations.

In contrast, drill depth signifies the total measured length of the drill string from the surface reference point down to the drill bit at the very bottom of the hole. It represents the actual extent of the wellbore that has been drilled and is continuously updated as drilling progresses. While a wireline tool might be run to the current drill depth, wireline depth specifically pertains to the operational depth of the wireline equipment, distinct from the total drilled penetration of the well.

What is the wireline drilling method?

The wireline drilling method is an advanced and highly efficient technique primarily used for core drilling in geological exploration. Its core principle involves retrieving core samples without needing to dismantle and remove the entire drill rod string from the borehole. Instead, a specialized core barrel assembly is precisely lowered to the bottom of the drill hole using a wireline cable.

Once the core barrel is full, it’s quickly pulled back to the surface via the same wireline, leaving the main drill rods undisturbed in the hole. This innovative approach significantly minimizes “tripping” time, leading to a substantial increase in drilling productivity and a reduction in overall operational costs. It is especially advantageous for drilling deep boreholes where maximizing efficiency and rapid sample retrieval are critical.

Send Your Inquiry Now

All-in-one Wireline Drill Rods Solutions for Your Project

We provide all-in-one taper drill rod solutions to simplify your drilling projects. Our extensive range offers high-quality rods suitable for various rock conditions and drilling machines, ensuring optimal performance and durability. From material selection to custom lengths and specialized coatings, we tailor solutions to meet your exact needs, maximizing productivity and reducing downtime for your specific application.