Custom TCI Tricone Drill Bit Manufacturer in China

We offer high-performance TCI (Tungsten Carbide Insert) Tricone Drill Bits, designed for superior efficiency and durability across diverse drilling applications. These bits feature robust tungsten carbide inserts pressed into the cones, providing exceptional wear resistance and cutting capability. Ideal for medium to hard rock formations, our TCI tricone bits ensure high rates of penetration and extended tool life in oil & gas, mining, water well, and geothermal drilling.

Sinodrills - Your Trusted TCI Tricone Drill Bit Manufacturer from China

Sinodrills stands as a trusted TCI Tricone Drill Bit manufacturer from China, renowned for delivering high-quality, durable drilling solutions. With extensive experience in the industry, we specialize in producing TCI tricone bits engineered for optimal performance in diverse rock formations. Our commitment to advanced manufacturing processes and stringent quality control ensures reliable, efficient, and long-lasting drill bits for global drilling operations.

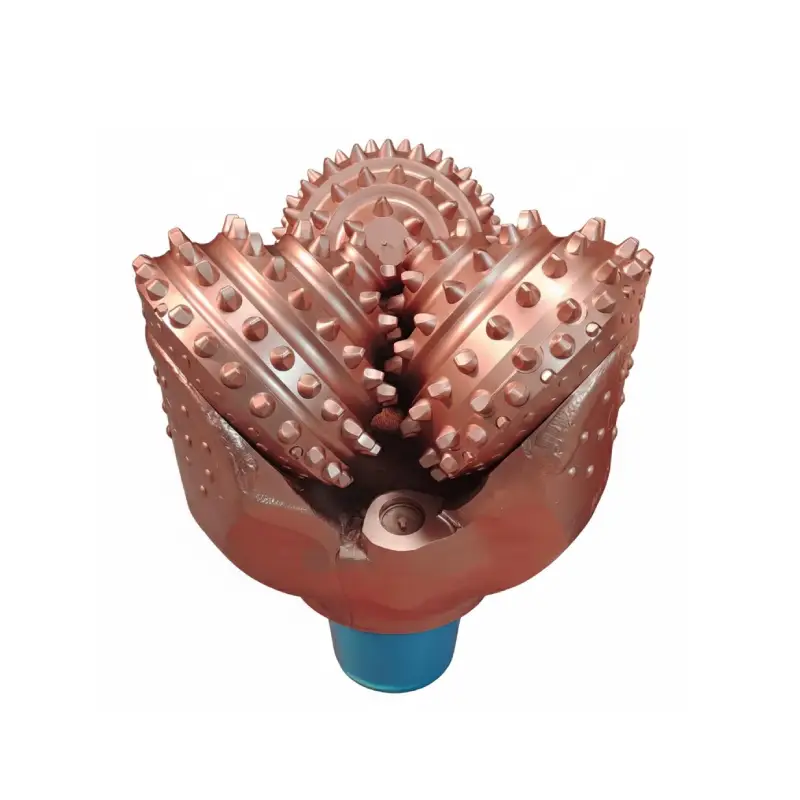

Pin Connection: The threaded upper part that connects the bit to the drill string, transmitting rotational force and weight.

Cutter Cones: The rotating elements with tungsten carbide inserts (TCI) that crush and grind the rock formation.

Tungsten Carbide Inserts (TCI): Extremely hard buttons or teeth pressed into the cones, responsible for the actual rock cutting. (Specifically, Gauge Inserts, Shirttail Inserts, Nose Inserts, and Cutter Cone Inserts)

Bearings (Ball Bearing, Inner and Outer Roller Bearing, Journal (R) Thrust Buttons): Allow the cones to rotate freely on the bit body while withstanding significant loads and high rotational speeds.

Air Tube & Nozzle: Part of the air circulation system (in this specific bit design) that directs compressed air to clean the bit face and remove cuttings.

Gauge Protection (Gauge Inserts, Gauge Bevel Inserts, Shirttail Hardfacing): Features designed to maintain the full diameter of the borehole by preventing excessive wear on the bit’s outer edge.

TCI Tricone Drill Bit Components

Various TCI Tricone Drill Bit

TCI tricone drill bits for rotary drilling

We specialize in offering and supplying TCI (Tungsten Carbide Insert) tricone drill bits, engineered specifically for efficient rotary drilling in diverse geological conditions. Our bits feature premium tungsten carbide inserts for superior wear resistance and extended bit life, ensuring optimal penetration rates in medium to hard formations. Ideal for oil & gas, water well, and mining applications, these robust tools deliver reliable performance and reduce overall drilling costs.

TCI Tricone Bits for Very Soft Formations

These tricone drill bits feature large diameter, widely spaced, and highly projected conical or chisel-shaped tungsten carbide inserts. Designed for formations with very low compressive strength and high drillability, such as clay, shale, and soft limestone, they maximize penetration rates by allowing deep insert penetration and preventing bit balling in sticky conditions.

TCI Tricone Bits for Hard Formations

Designed with an increased number of smaller, more closely spaced hemispherical or conical inserts, these bits excel in hard formations with high compressive strength, such as hard limestone, dolomite, and firm sandstone. The robust cutting structure and reinforced gauge protection ensure durability and consistent performance.

TCI Tricone Bits with Sealed Journal Bearings

We supply bits with advanced sealed journal bearing systems, which provide superior lubrication and protection from drilling fluids and debris. This significantly extends the bit’s lifespan and allows for higher RPMs and weights on bit, particularly critical in challenging or deep drilling applications, ensuring sustained performance.

TCI tricone bits for heavy rock drilling

We supply bits with advanced sealed journal bearing systems, which provide superior lubrication and protection from drilling fluids and debris. This significantly extends the bit’s lifespan and allows for higher RPMs and weights on bit, particularly critical in challenging or deep drilling applications, ensuring sustained performance.

Open Bearing TCI Tricone Drill Bits

We supply bits with advanced sealed journal bearing systems, which provide superior lubrication and protection from drilling fluids and debris. This significantly extends the bit’s lifespan and allows for higher RPMs and weights on bit, particularly critical in challenging or deep drilling applications, ensuring sustained performance.

Gauge Protected TCI Tricone Drill Bits

These TCI tricone drill bits incorporate additional wear-resistant features on the gauge (the outer diameter of the bit) to maintain hole size in abrasive formations. This protection often includes hard-facing, diamond inserts, or additional tungsten carbide inserts on the shirttail and heel row, preventing premature gauge wear and ensuring a consistent borehole diameter.

Air-Cooled TCI Tricone Drill Bits

These TCI tricone drill bits incorporate additional wear-resistant features on the gauge (the outer diameter of the bit) to maintain hole size in abrasive formations. This protection often includes hard-facing, diamond inserts, or additional tungsten carbide inserts on the shirttail and heel row, preventing premature gauge wear and ensuring a consistent borehole diameter.

Fixed Cutter Hybrid TCI Tricone Drill Bits

Our fixed cutter hybrid TCI tricone drill bits combine the durability of tungsten carbide inserts with efficient cutting performance. We offer precision-engineered bits designed for tough rock formations, providing faster drilling, longer lifespan, and reliable operation. Perfect for demanding industrial and oilfield applications, they deliver consistent results every time.

tricone drill bits for hard rock drilling

Our tricone drill bits for hard rock drilling are engineered for maximum durability and penetration. We offer robust, precision-designed bits that handle tough rock formations efficiently. With optimized cutting structure and wear-resistant materials, they deliver consistent performance, longer service life, and reliable results, making them ideal for demanding drilling projects.

customized TCI tricone drill bits

We offer customized TCI tricone drill bits tailored to your specific drilling needs. Made with durable tungsten carbide inserts, these bits ensure superior penetration, long service life, and consistent performance. Ideal for various rock formations, our precision-engineered tricone bits deliver efficiency, reliability, and optimized drilling results for demanding industrial and mining projects.

TCI tungsten carbide insert tricone bit

TCI tungsten carbide insert tricone bits are engineered for tough drilling conditions, delivering strong impact resistance and long service life. We offer reliable TCI tricone bits with optimized inserts and bearing systems, ensuring stable performance in hard rock, mining, water well, and oilfield drilling applications worldwide.

3/4 inch TCI drill bits

We offer 3/4 inch TCI drill bits designed for reliable performance in hard and abrasive formations. Using tough tungsten carbide inserts and optimized cutting structures, our bits deliver stable drilling, long service life, and reduced downtime. Ideal for mining, quarrying, and construction projects requiring consistent penetration and durability.

tricone TCI drill bits for mining

Tricone TCI drill bits for mining, we offer reliable solutions for hard and abrasive formations. Featuring tungsten carbide inserts, optimized bearing systems, and balanced cutting structures, our bits deliver steady penetration, long service life, and reduced downtime. We support customization for sizes, seals, and formations across diverse mining operations worldwide.

Customize Your Desired TCI Tricone Drill Bit

Formation-Specific Optimization

We customize the TCI tricone drill bit’s cutting structure, including insert size, shape, and pattern, to perfectly match your target geological formation. Whether you’re drilling through very soft shales or extremely hard granite, our engineers will design the ideal tooth geometry and density to maximize penetration rates and ensure efficient rock removal, saving you time and money.

Bearing System Selection

We offer various bearing system options for your TCI tricone drill bit, including open bearings for less demanding applications and advanced sealed journal bearings for extended life in challenging conditions. Choosing the right bearing system is crucial for maximizing bit longevity and performance, especially in high-temperature or high-RPM drilling environments.

Gauge Protection Enhancement

For abrasive formations that can rapidly wear down the bit’s diameter, we can incorporate enhanced gauge protection on your TCI tricone drill bit. This includes specialized hard-facing on the shirttail, diamond inserts, or additional tungsten carbide inserts on the heel row. This customization ensures your borehole maintains its desired diameter throughout the drilling process, preventing costly reaming.

Connection and Size Customization

We can tailor the API connection thread and overall diameter of your TCI tricone drill bit to seamlessly integrate with your existing drill string and rig specifications. This ensures perfect compatibility and safe, efficient operations on your drilling site. Our precision manufacturing guarantees a secure fit, minimizing downtime and maximizing productivity.

TCI Tricone Drill Bit Features

- Versatile Formation Capability: TCI tricone drill bits excel across a broad spectrum of rock strengths, from soft and medium to very hard and abrasive formations. This versatility stems from the ability to customize the size, shape, and projection of the tungsten carbide inserts, allowing them to efficiently crush, chip, or shear different rock types where other drill bit types might struggle or be less efficient.

- Enhanced Durability and Extended Life: The use of high-strength tungsten carbide inserts, coupled with robust cone and bearing designs, provides TCI tricone bits with exceptional durability. Unlike roller cone bits with milled steel teeth, TCI inserts maintain their cutting edge longer, leading to extended bit life, reduced trips, and significant cost savings in drilling operations.

- Optimized Bearing Systems: TCI tricone drill bits often feature advanced sealed journal bearing systems. These sophisticated lubrication and sealing mechanisms protect the bearings from the harsh downhole environment, allowing for higher rotational speeds (RPMs) and increased weight on bit (WOB). This results in faster penetration rates and a longer operational lifespan compared to open bearing or simpler bit designs.

- Effective Hole Cleaning and Gauge Keeping: The design of TCI tricone bits, particularly with optimized jet nozzles and robust gauge protection, ensures excellent hole cleaning by efficiently directing drilling fluid to remove cuttings. The inclusion of gauge inserts and hard-facing on the shirttail helps maintain the desired borehole diameter, preventing costly reaming and ensuring smooth casing installation.

TCI Tricone Drill Bit Applications

Oil and Gas Well Drilling

We extensively use TCI tricone drill bits for drilling oil and gas wells, from surface holes to deep reservoir sections. Their ability to handle varying rock hardness and provide high penetration rates makes them indispensable for efficient and cost-effective extraction of hydrocarbons.

Mining and Exploration

For mineral exploration and mining operations, we deploy TCI tricone drill bits to penetrate various ore bodies and overburden. Their robust construction and capability to drill through hard, abrasive rock ensure reliable performance in demanding mining environments, facilitating resource discovery and extraction.

Water Well Drilling

We rely on TCI tricone drill bits for drilling water wells in diverse geological settings. Whether it’s unconsolidated sediments or hard rock aquifers, our bits provide the necessary efficiency and longevity to access vital groundwater resources for agricultural, industrial, and municipal use.

Geothermal and Geotechnical Drilling

We apply TCI tricone drill bits in geothermal projects to access heat reservoirs and for various geotechnical investigations. Their ability to perform in high-temperature conditions and challenging formations makes them ideal for exploring and harnessing geothermal energy, as well as for ground stabilization and site characterization.

All-in-one TCI Tricone Drill Bit Solutions for Your Project

Sinodrills provides all-in-one TCI Tricone Drill Bit solutions, offering a comprehensive range of high-performance bits tailored for any project. From very soft to extremely hard formations, our TCI tricone drill bits deliver superior durability, extended lifespan, and faster penetration rates. We customize cutting structures, bearing systems, and gauge protection, ensuring optimal efficiency and cost-effectiveness for your specific drilling challenges.