Selecting the correct bit head design for DTH drill bits is critical for achieving optimal drilling performance. Each design affects penetration rate, durability, and efficiency, depending on rock type and drilling conditions. Understanding the key differences ensures smoother operations and reduces wear and downtime, saving both time and cost.

DTH bit head designs vary from button bits to cross bits, each tailored for specific applications. Factors like rock hardness, hole diameter, and drilling speed determine which design will deliver the best results. Choosing the right bit enhances productivity, extends tool life, and ensures a safer drilling environment.

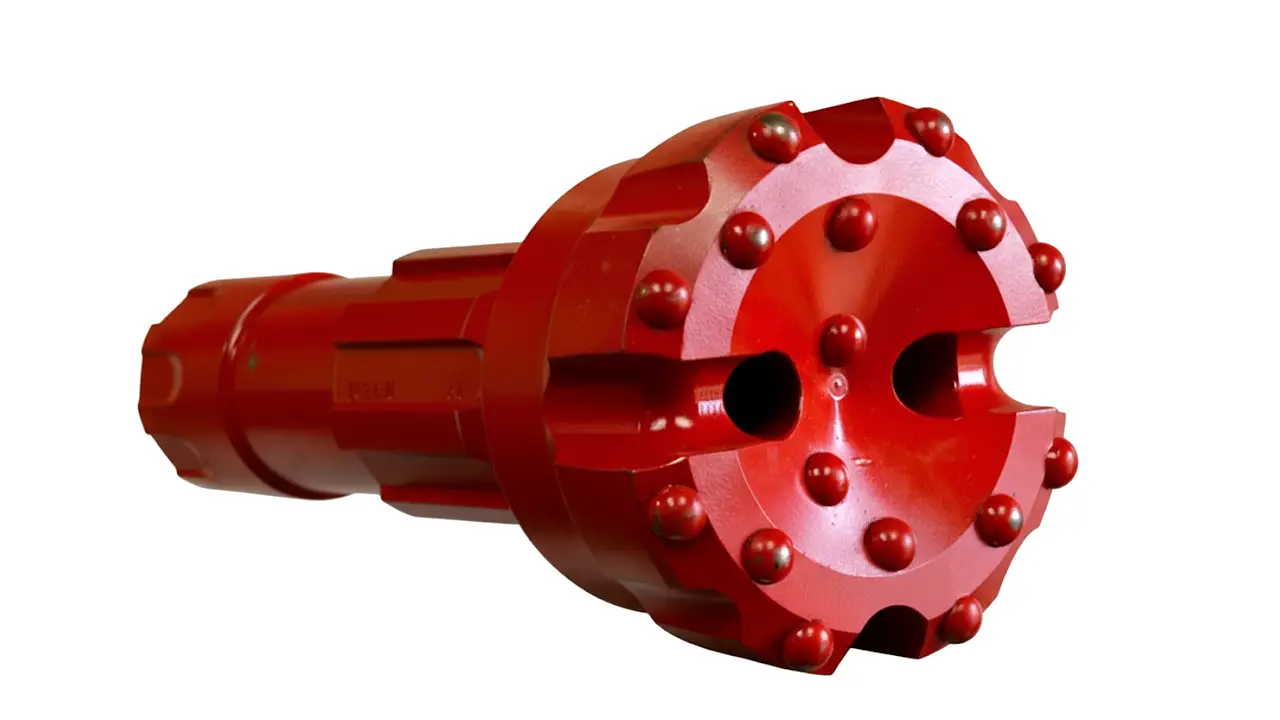

1. Flat Face Design

Quote Us Now

The flat face DTH drill bit has a smooth, continuous end surface. Due to its simple design, it is the most durable type of DTH bit and is considered a universal bit that can be used under all rock conditions.

It is best suited for fractured or very hard, as well as highly abrasive rock formations. However, due to its flat head, compared to the concave DTH drill bits, its drilling speed and hole straightness are lower. Thus, this drill bit is also suitable for drilling holes where high straightness is not required in medium-hard and soft rocks.

2. Concave Design

Quote Us Now

The concave face drill bit features a slight conical depression on its end face. The conical surface provides good stability and efficient chip removal during drilling, ensuring straightness, particularly in deep hole drilling , it can improve hole alignment as a result of the inverted pilot. It is suitable for medium hard to hard formations, less abrasive, and fractured rock conditions.

3. Convex Design

Quote Us Now

The primary purpose of the convex face design of DTH drill bits is to enhance drilling efficiency. Suitable for soft to medium hard rock formations, as well as non-abrasive rock types, this design allows for a good combination of high drilling efficiency and long service life in these rock types.

Typical rock types: Limestone, Hard Limestone, Shale, Granite, Basalt

Each head design of DTH drill bits has its unique advantages and suitable applications. In selecting the appropriate head design, factors such as geological conditions, operational requirements, drill bit materials need to be considered comprehensively. By making scientific and reasonable selections and designs, the efficiency and precision of drilling operations can be significantly improved, reducing operating costs!

Conclusion

Choosing the correct DTH bit head design requires careful consideration of rock type, drilling speed, and operational conditions. Selecting a bit that matches your needs enhances penetration efficiency, minimizes wear, and lowers overall drilling costs, ensuring consistent performance for every project.

Understanding the differences between bit head types, such as button, cross, or blunt bits, is essential for optimal drilling results. The right selection reduces downtime, improves accuracy, and protects equipment, giving drilling teams confidence in their operations.

For reliable, durable, and efficient drilling solutions, get wholesale DTH drill bits from our Sinodrills. We offer a wide range of bit designs suited for various rock formations, ensuring high performance and long service life for all your drilling projects.