Improving drilling efficiency is a critical goal for any project, impacting everything from project timelines to overall costs. The key often lies not in the drilling rig itself, but in the tools you select. Choosing the right drill bits and drill rods can significantly boost performance, reducing downtime and optimizing your drilling operations for maximum productivity.

This blog will guide you through the process of selecting the ideal drilling tools for your specific needs. We’ll explore the various types of drill bits and rods available on the market and how their unique features can be leveraged to enhance your drilling efficiency and ensure successful project completion.

Factors Affecting Improving Drilling Efficiency

Drilling efficiency is a complex process influenced by a multitude of variables. Achieving optimal performance requires a holistic approach, considering not just the equipment but also the geological conditions and operational techniques. By understanding and addressing these key factors, you can significantly enhance productivity and reduce costs on any drilling project.

- Drill bit design and material: The choice of drill bit is paramount. Selecting a bit with the correct cutting structure and material for the specific rock type can drastically increase penetration rates. The design, including the number and placement of cutting elements, directly impacts how effectively the bit breaks the rock.

- Drilling fluid properties: A properly engineered drilling fluid is essential for effective hole cleaning and cooling the drill bit. It helps to remove rock cuttings from the wellbore, which prevents recirculation and excessive wear on the bit. The fluid’s viscosity and density must be carefully managed to maintain wellbore stability.

- Drill rig parameters (weight on bit, rotary speed): Optimizing the rig’s operating parameters is crucial for maximizing efficiency. The weight on bit (WOB) and rotary speed (RPM) must be carefully balanced to achieve the highest penetration rate without causing damage to the bit or drill string.

- Formation characteristics (rock type, hardness): The geological formation’s properties directly dictate the ideal drilling approach. Hard, abrasive rock requires a different bit and set of parameters than soft, porous rock. Understanding the formation’s composition and hardness helps in selecting the most effective drilling strategy.

- Wellbore stability and hole cleaning: Maintaining a stable wellbore is critical to prevent stuck pipe and lost circulation. Efficient hole cleaning, which involves the proper removal of cuttings, prevents packed-off conditions and ensures the drill bit can continually engage fresh rock, thus maintaining a high rate of penetration.

- Drill string configuration and vibration control: The layout of the drill string, including stabilizers and collars, can significantly impact performance. Proper configuration minimizes unwanted vibrations, which can cause premature bit wear and equipment failure. Controlling these vibrations leads to smoother drilling and increased bit life.

- Operator experience and training: The skill level of the drilling operator is a significant factor. An experienced operator can recognize subtle changes in drilling conditions and make real-time adjustments to WOB, RPM, and fluid flow. Proper training ensures safe and efficient operations, minimizing costly mistakes.

Drilling Efficiency Formula

In drilling, efficiency is most commonly measured using the concept of Mechanical Specific Energy (MSE). This formula quantifies the amount of energy required to remove a unit volume of rock, providing a crucial metric for evaluating bit performance and optimizing drilling parameters. The goal is to minimize MSE, as a lower value indicates that the energy applied is being used more effectively to break rock rather than being wasted through vibrations or friction. The formula, originally proposed by Teale, combines the energy from both the axial force (weight on bit) and the rotational force (torque) to provide a comprehensive measure of the mechanical work being done at the bit.

The standard formula for calculating MSE is:

- WOB = Weight on Bit

- Ab = Bit Area

- RPM = Rotational speed of the bit

- T = Torque

- ROP = Rate of Penetration

The formula essentially breaks down the total energy input into two main components: the energy from the axial load (WOB) and the energy from the rotational torque.

By analyzing how MSE changes with different drilling parameters, engineers can make real-time adjustments to WOB and RPM to maximize the rate of penetration and minimize energy consumption. This not only leads to faster drilling but also reduces wear and tear on the drill bit and other downhole components, ultimately improving overall project economics.

Drilling Efficiency Formula Calculator

Result:

How to Improve Drilling Efficiency in Mining?

Achieving higher drilling efficiency in mining is crucial for boosting productivity and controlling costs. By systematically addressing key operational areas, mines can significantly increase their rate of penetration and reduce downtime. This requires a comprehensive approach focusing on tools, technology, and technique.

Optimizing Drill Bit and Tool Selection

The type of rock being drilled is a primary factor. Selecting a drill bit with the optimal cutting structure and material for the specific geological formation is crucial. Matching the bit to the rock ensures maximum penetration rates and minimizes premature wear, which extends the bit’s life and reduces changeover time.

Beyond the bit, the entire drilling tool system must be considered. Choosing the right drill rod and accessories that are compatible and in good condition prevents failures and reduces vibration. High-quality tools are an investment that pays off by improving performance and ensuring consistent, reliable operations.

Enhancing Drilling Rig and Operational Parameters

Properly adjusting the rig’s operating parameters is fundamental to efficiency. The weight on bit (WOB) and rotary speed (RPM) must be precisely balanced. This combination is key to achieving the highest possible penetration rate without causing excessive stress on the equipment, which can lead to costly damage.

Operators must also be trained to manage these parameters dynamically, adjusting them in real-time as they encounter different rock strata. An experienced operator can recognize subtle changes in drilling conditions, fine-tuning the rig’s settings to maintain peak efficiency throughout the drilling process.

Implementing Proactive Maintenance

Regular, proactive maintenance of all drilling equipment is essential to avoid unexpected failures. This includes routine inspection and replacement of worn components like drill bits and rods before they break down. A well-maintained fleet experiences less downtime, keeping drilling operations running smoothly.

A structured maintenance schedule not only prevents catastrophic failures but also ensures that all tools are operating at their best. This approach to asset management reduces long-term costs by extending equipment lifespan and guaranteeing that every piece of machinery contributes to the overall drilling efficiency.

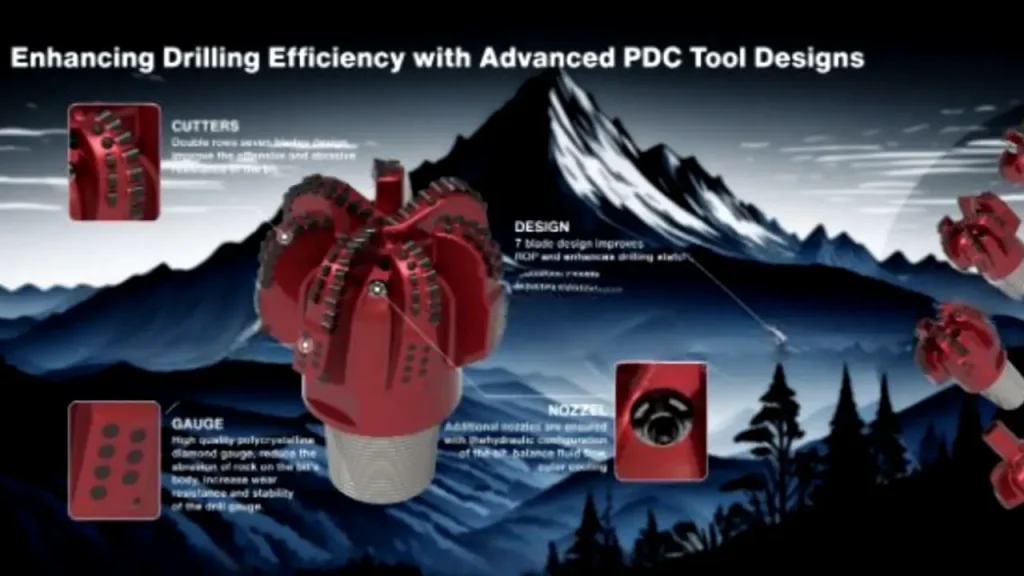

Enhance Drilling Efficiency With the PDC Arc Drill Bit-5 Wings

The PDC (Polycrystalline Diamond Compact) Arc Drill Bit with 5 wings is engineered to significantly enhance drilling efficiency in soft to medium-hard rock formations. Its advanced design, featuring five blades and arc-shaped cutting wings, distributes the cutting force more evenly across the bit face, which reduces wobble and improves stability.

This specialized geometry, combined with PDC cutters, allows for a more aggressive yet smooth drilling action, leading to faster penetration rates and a longer bit lifespan by minimizing premature wear. The design also optimizes fluid dynamics, efficiently flushing cuttings away from the cutting face.

- Improved Stability: The five-wing design provides a balanced, stable drilling action, reducing vibration and torque fluctuations.

- Faster Penetration Rates: The aggressive cutting structure and optimized fluid flow allow the bit to shear through rock more quickly.

- Extended Bit Life: Evenly distributed cutting force and enhanced cooling from the fluid channels significantly reduce cutter wear.

- Effective Hole Cleaning: Arc-angle wings and strategically placed nozzles ensure cuttings are removed efficiently, preventing bit balling.

Conclusion

Ultimately, optimizing your drilling performance is a direct result of informed tool selection. By carefully considering factors like ground conditions, drilling depth, and material type, you can match your needs with the most suitable drill bits and rods. This strategic approach not only enhances operational speed but also extends the life of your equipment.

The right drilling tools are an investment in your project’s success and profitability. We’ve seen how specific designs and materials can make a substantial difference in efficiency, leading to less wear and tear and a reduction in operational costs over time. Making the right choice upfront pays dividends.

For top-tier performance and reliability, consider our extensive range of high-quality drilling tools. At Sinodrills, we offer a comprehensive selection of wholesale drilling tools designed to meet the demands of any project. Contact us today to learn more about how our products can help you achieve superior drilling efficiency.