Custom Diamond Impregnated Bits Manufacturer in China

Source and choose your ideal diamond impregnated bits directly from our top-tier Chinese manufacturing partners. We provide a broad range of bits engineered for superior performance and longevity in all rock types, from soft to extremely hard. Our products guarantee faster penetration and reduced operational costs, ensuring maximum efficiency for your project.

Sinodrills - Your Trusted Diamond Impregnated Bits Manufacturer from China

Sinodrills is your trusted partner for diamond impregnated bits manufactured in China. We specialize in producing bits with superior diamond distribution and matrix hardness, ensuring exceptional performance in the toughest rock formations. Our commitment to advanced technology and quality control guarantees you get reliable, long-lasting bits that boost your drilling efficiency and profitability.

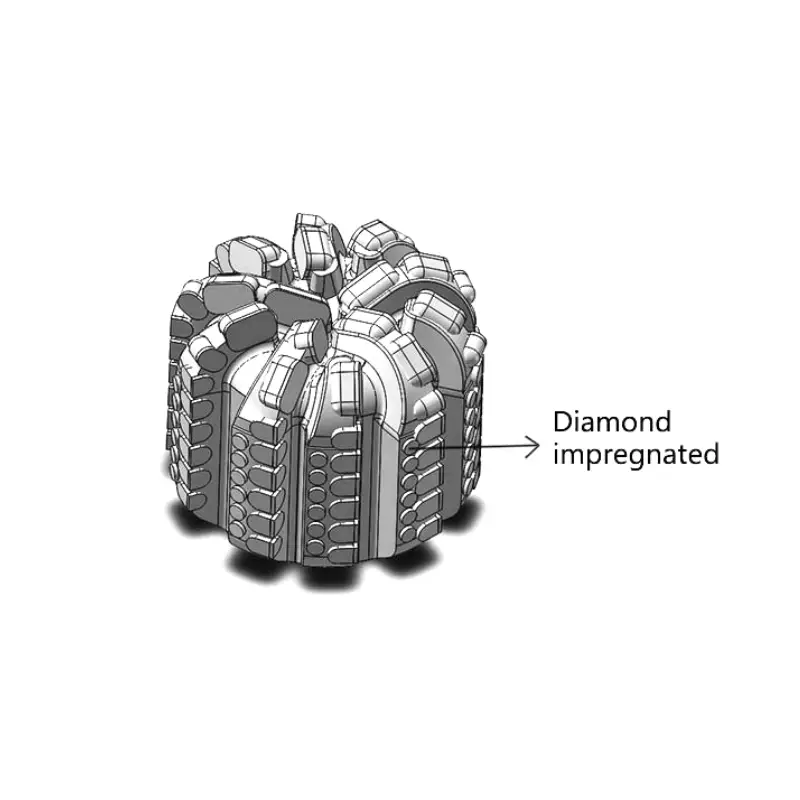

Diamond Impregnated Bit Design

Diamond impregnated bits are drilling tools used in the mining and exploration industries, featuring a steel body with a diamond-impregnated crown. The crown’s matrix is a mix of metal powders and industrial-grade diamonds. As the bit rotates, the matrix wears away, exposing new diamond particles that continuously cut and grind through hard rock formations.

Diamond Impregnated Bit Benefits

Exceptional Durability and Long Life: The bit’s crown is a matrix of metal powders and industrial-grade diamonds. As the bit drills, the matrix wears away, constantly exposing new diamond cutting surfaces. This self-sharpening action gives the bit an extremely long service life compared to bits with a single layer of diamonds.

High Performance in Hard Formations: Impregnated bits are specifically designed to cut and grind through very hard, consolidated, and abrasive rock formations like granite, basalt, and quartzite. They can maintain a consistent penetration rate in conditions where other bits would wear out quickly.

Versatility: These bits are highly versatile and can be used in a wide range of geological formations, from hard and non-abrasive to fractured and broken ground. This reduces the need for frequent bit changes, saving time and money.

Cost-Effectiveness: While they may have a higher initial cost, their extended lifespan and efficiency in difficult drilling conditions make them more cost-effective in the long run. They minimize downtime for bit changes and can drill more meters per bit.

Various Diamond Impregnated Bits

dual cutting diamond impregnated bits

We offer a line of dual-cutting diamond impregnated bits designed for drilling through ultra-hard and abrasive formations. These bits combine the shearing action of PDC cutters with the grinding of a diamond-impregnated matrix. As the formation becomes harder, the PDC cutters wear down, exposing the impregnated matrix. This dual-action design extends bit life and increases penetration rates in various rock types.

6 wing diamond impregnated bits

We offer 6-wing diamond impregnated bits, engineered for superior performance in even the most challenging rock formations. The six-wing design enhances stability and water flushing, resulting in faster penetration and a longer bit lifespan. Our bits provide a cost-effective solution for deep hole drilling and mineral exploration.

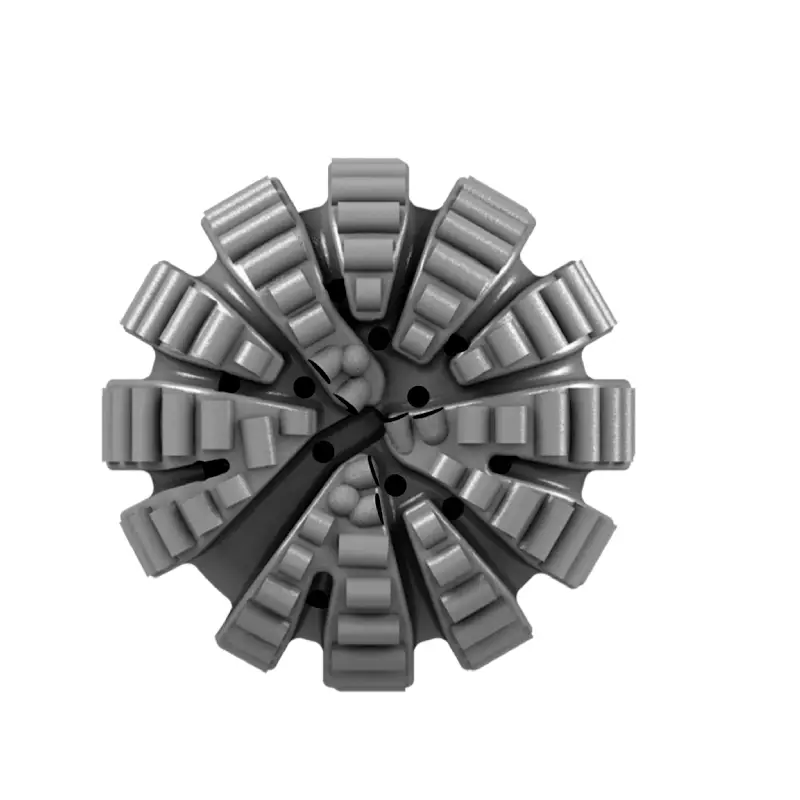

matrix blade diamond impregnated bits

We offer matrix blade diamond impregnated bits, a robust and reliable choice for drilling through the toughest geological formations. This design features a tungsten carbide matrix that securely holds diamonds, ensuring exceptional wear resistance and durability. The bit’s multiple blades enhance stability, while the self-sharpening matrix maintains a consistent rate of penetration, reducing downtime and increasing overall efficiency.

customized diamond impregnated bits

We offer customized diamond impregnated bits to perfectly match your specific drilling needs. Our engineering team will work with you to determine the ideal combination of matrix hardness, diamond size and concentration, crown profile, and waterway design. This ensures maximum penetration and bit life for your unique geological formations, saving you time and money on every project.

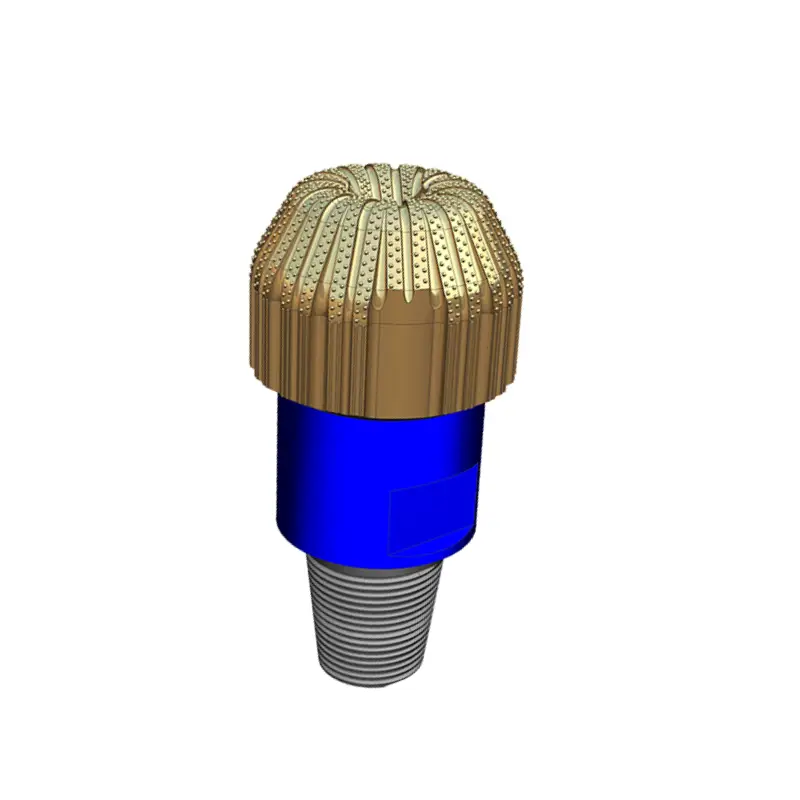

NQ impregnated diamond core bit

We provide NQ impregnated diamond core bits engineered for drilling hard and abrasive rock formations. Manufactured with diamond matrix, these bits ensure excellent penetration rates, durability, and reliable performance. Ideal for mineral exploration and geological core drilling, our NQ impregnated diamond core bits deliver precise results, extended service life, and cost-effective drilling solutions.

matrix body impregnated diamond drill bit

We provide matrix body impregnated diamond drill bits built for superior performance in hard and abrasive formations. Featuring a durable matrix body and evenly distributed diamonds, these bits deliver consistent cutting, longer lifespan, and reliable penetration rates. Ideal for geological exploration, mining, and core drilling, they ensure efficiency, durability, and precision in challenging drilling environments.

customized impregnated diamond drill bit

We specialize in providing customized impregnated diamond drill bits for diverse drilling applications. Our expertise covers tailoring matrix hardness, diamond concentration, and crown profile to optimize performance in specific geological formations, ensuring superior penetration rates and extended bit life for our customers’ unique needs.

fast speed borehole geological diamond core impregnated drill bit

We offer fast speed borehole geological diamond core impregnated drill bits designed for reliable drilling in hard and abrasive formations. Featuring premium diamond impregnation, these bits ensure faster penetration, excellent wear resistance, and extended service life. Perfect for geological exploration and core sampling, they deliver consistent performance and efficiency in challenging drilling applications worldwide.

Customize Your Desired Diamond Impregnated Bits

Diamond Concentration and Size

We can adjust the concentration and size of the diamonds within the bit’s matrix. A higher concentration typically means more diamonds per unit volume, while larger diamonds offer more aggressive cutting. The right balance depends on the rock hardness and desired penetration rate, ensuring optimal performance for your specific drilling conditions.

Matrix Hardness

The matrix hardness determines how quickly the bit wears to expose new diamond cutting surfaces. A harder matrix is ideal for drilling through softer, more abrasive rocks, preventing the diamonds from being dislodged too quickly. Conversely, a softer matrix is better for harder, less abrasive formations, allowing the bit to expose fresh diamonds efficiently.

Crown Profile and Waterways

We can customize the crown profile and waterways to optimize flushing and cutting efficiency. Options include face discharge, which directs fluid to the bit face for better cleaning, or internal fluid passageways that improve cooling and cuttings removal. The crown profile, like a concave or convex shape, also influences how the bit engages the rock.

Bit Body and Thread Type

The bit’s body material and thread type are crucial for durability and compatibility with your drill string. We can select from various steel alloys for the body, choosing a grade that provides the necessary strength for your application. We’ll also ensure the thread connection matches your existing equipment, guaranteeing a secure and reliable fit.

what are Diamond Impregnated Bits?

Diamond impregnated bits are specialized drill bits used in mining and construction that are designed to cut through extremely hard, abrasive formations.

Unlike surface-set bits that have a single layer of large, natural diamonds on the cutting face, impregnated bits contain a uniform mixture of small, industrial-grade synthetic diamonds distributed throughout a metal alloy matrix.

what are Diamond Impregnated Bits used for?

Diamond impregnated bits are specialized rotary drilling tools crucial for cutting through the world’s hardest, most abrasive materials like rock, concrete, and ceramic. Their design, which embeds industrial-grade diamonds in a metal matrix, allows for continuous self-sharpening and superior cutting power, making them indispensable in several industries where traditional bits fail.

-

Mineral Exploration and Geological Research: These bits are predominantly used in core drilling to extract intact, cylindrical rock samples from deep subsurface formations. Geologists analyze these core samples to map ore bodies, assess the presence and extent of valuable mineral reserves, and study the Earth’s structural and lithological composition for science.

-

Oil and Gas Drilling: In the energy sector, diamond impregnated bits are vital for penetrating extremely hard, abrasive intervals and interbedded sections encountered during exploratory and production drilling. Their durability and high rate of penetration in demanding downhole conditions improve efficiency, reduce drilling time, and lower overall operational costs.

-

Construction and Infrastructure Projects: Diamond bits are employed extensively for creating precise, clean holes in very hard materials like reinforced concrete, masonry, and stone for foundation work, utility openings, and anchor installation. This technique, often called diamond core drilling, minimizes vibration and structural damage, providing superior accuracy for modern construction.

-

Manufacturing and Material Processing: They are essential tools in industries that require precision drilling through non-metallic hard materials like glass, porcelain, ceramic tiles, and gemstones. Their ability to cut these challenging materials efficiently and with minimal cracking or chipping makes them the go-to solution for high-precision, low-mess applications.

how do Diamond Impregnated Bits work?

Diamond impregnated bits are drill bits that work on a self-sharpening principle by exposing new, sharp diamond cutting surfaces as the bit wears down. They’re composed of synthetic diamonds uniformly mixed throughout a metal alloy matrix.

The Mechanism

As the bit spins and pressure is applied, the outermost layer of diamonds grinds against the rock. Simultaneously, the surrounding metal matrix slowly wears away. This controlled erosion of the matrix is what allows the bit to work.

Once the exposed diamonds become dull or break away, the matrix wears down further, revealing a fresh layer of sharp diamonds underneath. This cycle of wear and exposure continues throughout the life of the bit.

The hardness of the matrix is a critical design factor. For soft, abrasive rock, a harder matrix is used so it wears slowly, preventing the diamonds from being lost too quickly. For very hard rock, a softer matrix is used to wear faster, ensuring new diamonds are constantly exposed to maintain cutting efficiency.

Where to use Diamond Impregnated Bits?

Diamond impregnated bits are best suited for drilling in extremely hard and abrasive rock formations where other bits, like those with polycrystalline diamond compact (PDC) cutters, would wear out too quickly. Their ability to continuously expose new cutting surfaces makes them highly durable and efficient in these challenging environments.

Key applications for diamond impregnated bits include:

Mineral and Geological Exploration: This is a primary use case. Geologists and mining companies use these bits to drill deep into the earth and extract core samples from hard formations like granite, basalt, and various abrasive ore bodies. The core samples are crucial for assessing the presence, quality, and extent of valuable mineral reserves.

Oil and Gas Exploration: In the petroleum industry, these bits are used to drill through hard rock layers and reach oil and gas reservoirs, especially in unconventional drilling where formations are often hard and consolidated.

Construction and Infrastructure: Diamond impregnated bits are used for a variety of construction projects that require drilling into solid rock, such as creating foundations for buildings, bridges, and tunnels, or for drilling water wells in areas with hard rock.

Scientific Research: They are also used by scientists to retrieve rock cores from different geological formations for research into Earth’s history, structure, and composition.

Why Choose our Diamond Impregnated Bits?

Choosing our diamond impregnated bits means you’re investing in a solution designed for maximum efficiency and durability in the most challenging drilling conditions.

We prioritize quality and performance to deliver several key advantages:

Superior Longevity and Durability

Our bits are engineered for a long service life. The self-sharpening design, where new layers of diamonds are continuously exposed, ensures the bit maintains its cutting ability over an extended period. This reduces the frequency of bit changes, saving you valuable time and money on the job site.

Optimized for Hard Formations

We use carefully selected grades of synthetic diamonds and a custom-blended metal matrix. This combination is specifically optimized to cut through extremely hard, consolidated, and abrasive rock types like granite, basalt, and quartzite, which would rapidly wear out conventional bits.

Consistent Performance and High Penetration

Thanks to the uniform distribution of diamonds throughout the matrix, our bits deliver a consistent and predictable penetration rate. This reliability allows for more efficient drilling operations and helps you achieve your project goals on schedule.

Customizable to Your Needs

We understand that every drilling project is unique. We offer a range of customization options for diamond concentration, matrix hardness, and crown profiles. This allows us to tailor a bit specifically for your drilling rig, rock type, and desired performance, ensuring you have the perfect tool for the job.

Send Your Inquiry Now

All-in-one Diamond Impregnated Bits Solutions for Your Project

We offer a complete suite of diamond impregnated bits and complementary drilling accessories designed to work together seamlessly. From customized matrix hardness and diamond concentration to specialized waterways and crown profiles, our solutions are engineered to optimize your drilling performance, reduce downtime, and increase core recovery in the toughest rock formations. We provide the perfect tools to tackle your specific project challenges.