Custom Oil Drill Bit Manufacturer in China

Discover your perfect oil drill bits with our extensive selection. We offer a variety of cutting-edge drill bits engineered for different formations, ensuring you find the ideal tool to maximize your drilling efficiency and performance. From PDC to roller cone bits, we have the right solution to help you get your desired results, faster.

Sinodrills - Your Trusted Oil Drill Bit Manufacturer from China

As a leading oil drill bit manufacturer from China, Sinodrills provides reliable, high-performance drilling solutions. We specialize in producing a full range of drill bits, including PDC, roller cone, and diamond bits, crafted with advanced technology and strict quality control. Trust Sinodrills for superior performance and exceptional value on your next project.

Oil Drill Bit Uses

Drilling through various rock formations: Oil drill bits are specifically designed to penetrate and break apart different types of rock, from soft shale and sandstone to hard granite and limestone.

Creating a cylindrical wellbore: The bit’s purpose is to produce a wellbore of a specific diameter, which allows for the installation of casing and other equipment to maintain the integrity of the hole.

Directional and horizontal drilling: Specialized bits, particularly PDC bits, are used to steer the wellbore in a specific direction or to turn horizontally to access a wider area of the reservoir.

Core sampling: Certain bits are designed to cut and retrieve a cylindrical rock sample from the formation, which is then analyzed by geologists to understand the subsurface composition.

Well repair and reaming: Bits can be used for operations such as widening an existing wellbore (reaming) or clearing blockages and damaged sections of the hole.

Oil Drill Bit Benefits

Increased Rate of Penetration (ROP): Advanced bit designs and materials allow for faster drilling speeds, which reduces rig time and lowers overall drilling costs.

Extended Bit Life: Modern bits, made with durable materials like polycrystalline diamond compact (PDC) and tungsten carbide, are highly wear-resistant. This allows them to stay in the hole longer, reducing the need for costly “trips” to replace the bit.

Improved Wellbore Quality: Optimized cutting structures and hydraulic designs create a smoother, more consistent wellbore, which minimizes vibration, reduces equipment wear, and simplifies subsequent completion operations.

Enhanced Performance in Challenging Formations: Different types of bits are specifically engineered to handle various geological conditions, from soft shales to hard, abrasive sandstones, ensuring optimal performance regardless of the formation.

Superior Directional Control: Specialized bits, particularly in horizontal and directional drilling, provide better steerability, allowing operators to accurately guide the wellbore to the target reservoir.

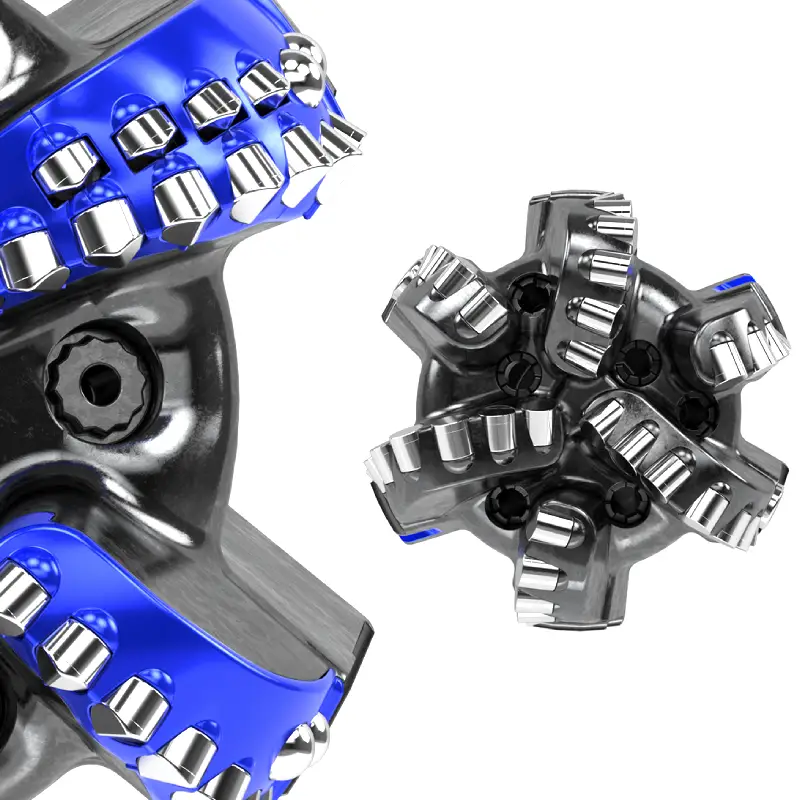

Various Oil Drill Bit

oil drilling drill bit

Discover your perfect oil drill bits with our extensive selection. We offer a variety of cutting-edge drill bits engineered for different formations, ensuring you find the ideal tool to maximize your drilling efficiency and performance. From PDC to roller cone bits, we have the right solution to help you get your desired results, faster.

drill bits for oil and gas industry

Drill bits are the critical tools in oil and gas drilling, designed to cut through diverse rock formations. We offer a comprehensive range of cutting-edge drill bits, including fixed cutter bits and roller cone bits, to maximize your drilling efficiency. Our bits are engineered for superior performance, durability, and a longer lifespan, reducing operational costs and improving your bottom line.

oil and gas drilling bits

We specialize in providing a comprehensive range of oil and gas drilling bits to meet diverse project needs. Our selection includes high-performance Polycrystalline Diamond Compact (PDC) bits for efficient shearing in various formations, as well as durable roller cone bits with tungsten carbide inserts for crushing hard rock. We offer customized solutions to optimize your drilling performance.

oil well drill bit

We have the drill bits for oil well, that are essential tools for creating boreholes for oil and gas extraction. We provide a comprehensive range of these bits, including fixed-cutter bits like PDC (Polycrystalline Diamond Compact) bits, which use diamond cutters to shear through hard rock formations, and roller-cone bits that use rotating cones to crush and fracture rock. Our selection ensures you get the right bit for optimal drilling efficiency.

diamond oil drill bit

We offer a premium selection of diamond oil drill bits, including both natural and synthetic options, engineered for superior performance in the toughest formations. Our bits are designed to deliver exceptional wear resistance and high penetration rates in hard, abrasive rock, ensuring extended bit life and reduced drilling costs for your most demanding projects.

Customize Your Desired Oil Drill Bit

Cutting Structure

We can design the cutting structure with different types of cutters, such as Polycrystalline Diamond Compact (PDC) for shearing or Tungsten Carbide Inserts (TCI) for crushing. Our engineers select the optimal cutter size, shape, and placement to maximize the Rate of Penetration (ROP) for your specific rock formations.

Body Material

We offer both steel body and matrix body bits. A steel body bit is durable and easy to repair, while a matrix body bit offers high resistance to erosion and can handle higher cutter density. We choose the body material based on your wellbore conditions and drilling environment.

Hydraulics

The hydraulic design is crucial for cleaning the hole and cooling the cutters. We customize the nozzle count, size, and placement to ensure effective cuttings removal and prevent bit balling. This aspect is vital for maximizing drilling efficiency and extending the bit’s life in soft or sticky formations.

Size

The bit size is a fundamental aspect we customize, as it directly determines the diameter of the wellbore. We manufacture bits in a wide range of standard and non-standard sizes, from a few inches for specialized applications to over a foot for large-diameter drilling, ensuring a perfect match for your project’s casing and hole requirements.

How Does an Oil Drill Bit Work

An oil drill bit works by utilizing a combination of weight, rotation, and fluid circulation to break and remove rock formations. The bit, attached to the end of a long drill string, is rotated from the surface.

The weight of the drill string and the bottom-hole assembly is applied to the bit, pushing its cutting elements against the rock. As it rotates, the bit’s cutters either crush and gouge the rock (like a roller cone bit) or shear and scrape it away (like a fixed-cutter PDC bit).

Simultaneously, a specialized fluid, known as drilling mud, is pumped down the drill pipe, exiting through nozzles in the bit.

This fluid serves multiple purposes: it cools and lubricates the bit, and it carries the broken rock fragments (cuttings) up the annulus (the space between the drill pipe and the wellbore walls) to the surface, ensuring the wellbore remains clean and clear for continued drilling.

how much does an oil drill bit cost?

The cost of an oil drill bit varies dramatically based on several factors, making it impossible to provide a single price.

The price can range from a few hundred dollars for a small, used bit to well over $20,000 for a large, specialized, and brand-new diamond-enhanced bit.

The final cost is a function of the bit’s size, its material composition, and its intended application.

Type of Bit: Polycrystalline Diamond Compact (PDC) bits, which are made of synthetic diamonds, are generally more expensive than roller cone bits, especially those with tungsten carbide inserts (TCI).

Size and Diameter: Larger bits require more material and are more complex to manufacture, directly correlating with a higher price tag.

Manufacturer and Technology: Bits from leading global manufacturers, or those featuring proprietary designs and advanced cutting technology, will command a premium price over more basic or generic models.

Condition: New bits are significantly more expensive than used or re-tipped bits, which are reconditioned for another drilling run.

what are oil drill bits made of?

Drill bits used in oil and gas extraction are engineered with extremely hard, durable materials to withstand the immense forces and abrasive conditions of drilling through rock.

The choice of material depends on the type of bit and the specific geological formation it’s designed to penetrate. These materials are selected for their ability to maximize the rate of penetration (ROP) and extend the bit’s life, reducing the need for costly replacements.

Here are materials used in drill bits for oil and gas extraction in the following:

Steel: Used for the bit body in both roller cone and fixed-cutter bits. Steel bodies are strong and ductile, offering good resistance to impact, and are often “hard-banded” with tungsten carbide to resist abrasion.

Tungsten Carbide: A compound of tungsten and carbon, tungsten carbide is a very hard and wear-resistant material. It is used as inserts (TCI) in roller cone bits to crush hard rock and as the matrix material for fixed-cutter bit bodies.

Polycrystalline Diamond Compact (PDC): These synthetic diamonds are one of the hardest materials available for drilling. PDC bits feature cutters made of a diamond layer bonded to a tungsten carbide substrate. They are the go-to choice for drilling through a wide range of soft to hard formations due to their high ROP and long life.

Natural Diamond: Used in certain bits, particularly for drilling extremely hard, abrasive formations. Natural diamond particles are embedded in a metal matrix, which slowly wears away to expose fresh diamond cutting surfaces.

types of drill bits in oil and gas

Drill bits for oil and gas extraction are broadly categorized into two main types: fixed-cutter bits and roller cone bits. Each type is designed with a specific mechanism to break apart rock and is selected based on the rock formation’s characteristics, such as hardness and abrasiveness.

Roller Cone Bits

Also known as tri-cone bits because they typically have three cones, roller cone bits drill by crushing and chipping the rock. As the bit rotates, the individual cones on the bit’s face roll along the bottom of the wellbore. The cones feature teeth that fracture the rock under the weight of the drill string. There are two main sub-types of roller cone bits:

Milled-Tooth Bits: The teeth are a part of the steel cones themselves and are suitable for drilling softer formations, as they can gouge and scrape the rock more effectively.

Tungsten Carbide Insert (TCI) Bits: These bits have extremely hard tungsten carbide “inserts” or buttons pressed into the cones. TCI bits are more durable and are used for drilling hard, abrasive rock formations.

Fixed-Cutter Bits

Fixed-cutter bits have no moving parts and work by shearing and scraping rock away. The bit body, made of either steel or a tungsten carbide matrix, is fitted with fixed blades and cutters. This design is highly effective for drilling in a variety of formations, from soft to very hard.

Polycrystalline Diamond Compact (PDC) Bits: These are the most common fixed-cutter bits today. They feature synthetic diamond cutters bonded to a tungsten carbide substrate. PDC bits are highly efficient, offering fast drilling speeds in a wide range of formations and are particularly popular for horizontal and directional drilling.

Diamond Bits: These bits are impregnated with natural or synthetic diamonds and are used for drilling extremely hard and abrasive formations that would quickly dull other bit types. The bit’s cuttin

Send Your Inquiry Now

All-in-one Oil Drill Bit Solutions for Your Project

Sinodrills provides all-in-one oil drill bit solutions for your project’s every need. From our high-efficiency PDC bits to durable roller cones, we deliver a full suite of cutting-edge drill bits. Our integrated approach ensures you get the right tool, optimized for your specific geological conditions, to maximize performance and profitability from start to finish.