Custom Double Casing Drill Bit Manufacturer in China

Secure your project’s foundation with our robust double casing drill bits. Engineered for unparalleled performance in unstable ground, these drill bits simultaneously drill and advance the casing, providing a stable borehole in a single pass. Ideal for fractured rock, loose soil, and gravel, they ensure a clean, secure hole for your piles and anchors, minimizing risk and maximizing efficiency.

Sinodrills - Your Trusted Double Casing Drill Bit Manufacturer from China

Sinodrills is a leading manufacturer of double casing drill bits from China, offering a full range of high-quality rock drilling tools. We specialize in solutions that simultaneously drill and advance casing, ensuring stability in the most challenging formations. Trust us for reliable, cost-effective, and durable products designed to optimize your drilling performance.

Your Leading Double Casing Drill Bit Manufacturer from China

As a leading double casing drill bit manufacturer from China, we specialize in high-quality drilling tools that excel in challenging formations. Our drill bits are engineered to simultaneously drill and case a hole, providing a stable solution for projects in unstable ground. We are committed to delivering reliable, cost-effective tools that enhance your drilling efficiency and performance.

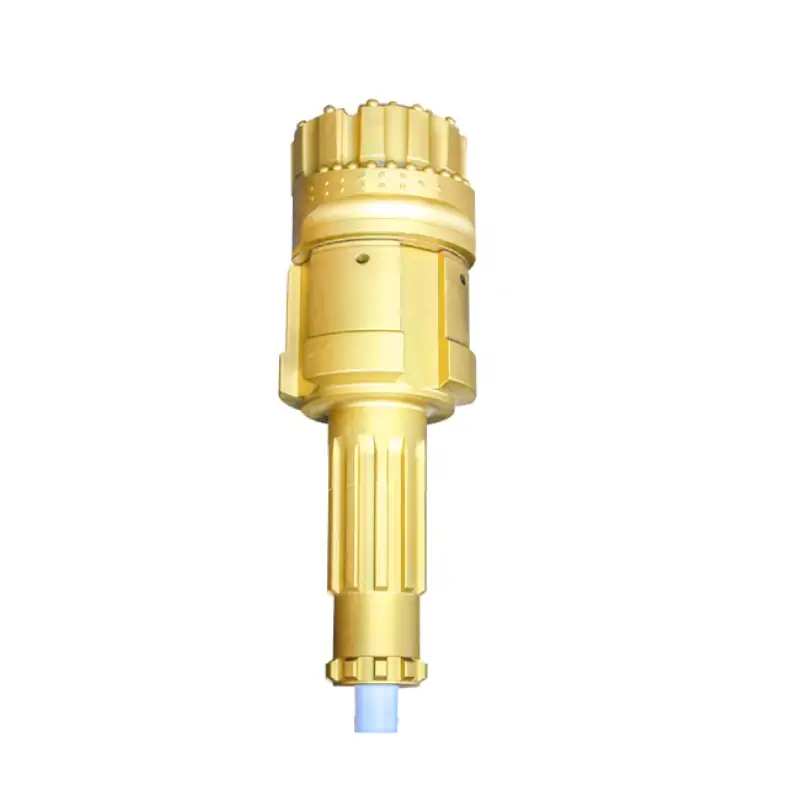

Double Casing Drill Bit Structure

Pilot Bit (Inner Bit): This central component leads the drilling process, penetrating the rock or soil with its carbide inserts or diamond cutters. It acts as the primary cutting tool, creating the initial bore.

Reamer (Outer Bit): Surrounding the pilot bit, the reamer widens the hole to the exact diameter required for the casing. Its cutting teeth or buttons effectively enlarge the bore, ensuring a smooth passage for the outer casing.

Casing Shoe: Integrated with the outer bit, the casing shoe is a robust ring that guides the casing into the freshly drilled hole. It protects the casing while facilitating its advancement into the ground.

Guide System: This internal mechanism ensures proper alignment and concentricity between the pilot bit, reamer, and casing. It allows for efficient transfer of drilling forces while maintaining the correct drilling path.

Connection Threads: Both the pilot bit and the overall assembly feature heavy-duty threads for secure attachment to the drill rods and casing. These connections ensure reliable power transmission and easy tool changes.

Various Double Casing Drill Bit

RC drilling rods with metzke thread

We offer a superior range of double casing drill bits designed to tackle the most challenging ground conditions. Our drill bits are engineered for simultaneous drilling and casing advancement, providing a single-pass solution for unstable formations, fractured rock, and gravel. This method prevents borehole collapse, ensuring a secure, clean hole and significantly improving drilling efficiency.

double casing system drill bit

We offer a premium range of double casing system drill bits, engineered for superior performance in the most challenging ground conditions. Our bits are designed to simultaneously drill and advance casing, providing maximum stability in loose soil, fractured rock, and gravel. We provide a full selection of sizes and types to meet your specific project needs.

double casing crown drill bits

We offer a premium range of double casing crown drill bits, expertly designed for efficiency in challenging rock formations. Our bits are engineered to simultaneously drill and case a borehole, providing superior stability in unconsolidated ground, fractured rock, and gravel. We provide a variety of sizes and designs to meet your specific project requirements.

eccentric overburden double casing drilling bits

We offer high-performance eccentric overburden double casing drilling bits designed for unstable ground. Our bits are engineered to simultaneously drill and case a borehole, utilizing an eccentric pilot bit that reams an oversized hole. This ensures a stable, clean hole through loose soil, gravel, and fractured rock, making your project more efficient and secure.

double casing drill bit for drilling hole

We offer high-performance double casing drill bits designed for drilling holes in unstable ground. Our bits simultaneously drill and advance the casing, creating a stable hole in a single pass. Ideal for fractured rock, gravel, and loose soil, they minimize the risk of collapse and ensure your project’s success.

double casing crown rock drilling bits

We offer high-performance double casing crown drill bits for demanding rock drilling applications. Our bits feature premium tungsten carbide inserts and robust designs for superior penetration rates and extended lifespan in hard, abrasive formations, ensuring maximum efficiency for your project.

double head casing system crown ring bit and inner bit

The double head casing system utilizes a crown ring bit (outer) and an inner bit (pilot bit) to simultaneously drill and case boreholes, offering superior control, especially in unstable or complex ground conditions like gravel or boulders. The inner bit can drill ahead of the casing or retract for better flushing containment, ensuring straight, deep holes for applications like water wells or geothermal drilling.

Customize Your Desired Double Casing Drill Bit

Pilot Bit and Reamer Design

We customize the pilot bit and reamer to suit the geology you’ll be drilling. For hard rock, we use tungsten carbide or PDC inserts for maximum penetration and durability. In softer formations, we can optimize the design for faster drilling and efficient spoil removal, ensuring peak performance and extended tool life.

Size and Diameter

We manufacture double casing bits in a wide range of diameters to accommodate various casing sizes and hole specifications. Whether you require a standard size or a custom diameter for a unique project, we ensure the fit is precise. This tailored approach guarantees seamless casing advancement and a secure, stable borehole.

Connection Type

We offer multiple connection options to ensure compatibility with your existing drilling rig and drill string components. From common API threads to custom designs, we guarantee a perfect, secure fit. A reliable connection is crucial for efficient power transfer and operator safety, and we prioritize both in our manufacturing.

Material and Hardness

We use wear-resistant materials to forge our double casing drill bits. The choice of steel and the hardening process can be adjusted to meet the demands of your specific application. This attention to material science ensures exceptional durability and longevity, reducing the need for frequent tool replacement and lowering overall project costs.

what is double casing in drilling?

Double casing is a specialized drilling technique that involves installing a smaller inner casing pipe within a larger outer casing pipe. This dual-layered system is crucial for providing enhanced structural integrity and stability to the borehole, especially when drilling through challenging or unstable geological formations like loose sand, gravel, or fractured rock.

The outer casing acts as a protective barrier, preventing the borehole walls from caving in, while the inner casing can be used to protect the drill string, circulate drilling fluids, or ensure the final borehole remains secure and free from contamination. This method significantly reduces the risk of borehole collapse, which can lead to project delays and increased costs.

what are double casing drill bits made of?

Double casing drill bits are made from a combination of robust materials to withstand the extreme forces and abrasive conditions of drilling. The main body of the bit is typically constructed from high-quality alloy steel, which provides the necessary strength and durability.

However, the true cutting power comes from the specialized materials used for the cutting elements. These inserts are meticulously selected and placed on the bit to maximize its effectiveness in various ground formations.

Tungsten Carbide: This is a very common material for the cutting inserts on both the pilot bit and the reamer. It is an extremely hard and wear-resistant metal compound that effectively crushes and breaks through hard rock formations, making it ideal for tough drilling conditions.

Polycrystalline Diamond Compact (PDC): For the most demanding applications, especially in medium to very hard rock, PDC cutters are used. These are made of a synthetic diamond layer bonded to a tungsten carbide substrate, providing exceptional hardness and wear resistance that allows the bit to shear through rock with high efficiency.

Steel: High-grade steel is used not only for the bit’s body but also for the casing shoe and other structural components. This steel is heat-treated and hardened to resist impact and abrasion, ensuring the entire assembly remains intact during the drilling and casing process.

Send Your Inquiry Now

All-in-one Double Casing Drill Bit Solutions for Your Project

We provide all-in-one double casing drill bit solutions, offering a complete system that combines drilling and casing in a single operation. Our tools are engineered to create a stable, clean borehole in one pass, dramatically increasing efficiency and reducing project time. We ensure you have the right tools for your specific geological needs.