Underground mining is a critical process that allows us to access valuable mineral resources deep within the Earth’s crust. It is a complex and highly specialized field that has evolved significantly over centuries, from early manual excavation to today’s highly mechanized and automated operations. This guide will provide a comprehensive overview of the modern underground mining industry.

It will delve into various mining methods, the advanced technology and machinery used, and the strict safety protocols that govern these operations. Whether you are a student, an industry professional, or simply curious about this fascinating field, this ultimate guide will equip you with a foundational understanding of underground mining.

What is Underground Mining?

Underground mining is a method of mineral extraction that involves excavating tunnels, shafts, and other openings to access ore bodies located deep within the Earth’s crust.

It is typically used when the mineral deposit is too deep to be economically or environmentally viable for surface mining. This method allows for the selective removal of valuable minerals while leaving the surrounding rock, resulting in a smaller surface footprint compared to open-pit mining. The process is complex, requiring advanced engineering and technology for safety, ventilation, and material transport.

What Drill Bits Are Needed for Underground Mining

Drill bits used in underground mining are specifically designed to penetrate hard rock formations efficiently and safely. The choice of bit depends heavily on the type of rock being drilled, with different designs optimized for varying hardness and abrasiveness. These tools are crucial for creating blast holes, bolting holes for ground support, and for exploration and production drilling.

Some common types of drill bits used in underground mining include:

- Button Bits: These bits have tungsten carbide inserts (buttons) and are widely used for their durability and high penetration rate in hard rock. They come in various shapes like spherical, ballistic, and parabolic, each suited for different rock conditions.

- Down-the-Hole (DTH) Bits: Designed to work with DTH hammers, these bits deliver powerful, high-frequency impacts directly to the rock face, making them highly effective for deep-hole drilling in very hard formations.

- PDC (Polycrystalline Diamond Compact) Bits: These bits use synthetic diamond cutters for superior wear resistance and cutting ability, making them ideal for drilling in medium to hard rock with minimal rotation.

- Tricone Bits: Featuring three rotating cones with either steel teeth or tungsten carbide inserts, these bits break rock through a crushing and shearing action. They are versatile and can be used in a wide range of rock formations, from soft to hard.

What Drill Rods Are Needed for Underground Mining

Drill rods, also known as drill pipes or drill steels, are a crucial component in underground mining as they transmit the rotational and percussive energy from the drilling machine to the drill bit. The specific type of rod needed depends on the drilling method, the depth of the hole, and the rock formation.

These drill rods are made from high-strength alloy steel to withstand extreme conditions, including high impact and torsional stress.

Recommended Drill Rods for Underground Mining

Common types of drill rods used in underground mining include:

- Integral Drill Rods: These rods have the drill bit and rod forged as a single piece. They are ideal for small-hole drilling and are often used with hand-held or air-leg rock drills. Their one-piece design reduces energy loss and makes them efficient for specific tasks.

- Extension Drill Rods: Also known as male-male (MM) rods, these rods have external threads on both ends and are connected using a separate coupling sleeve. They are a versatile choice for long-hole drilling and are widely used in tunneling and large-scale mining operations.

- Male/Female (MF) Rods: Unlike extension rods, MF rods have a male thread on one end and a female thread on the other. This design eliminates the need for a separate coupling, which reduces hole deviation and speeds up the process of adding or removing rods.

- Hexagonal and Round Drill Rods: These refer to the cross-sectional shape of the rod. Hexagonal rods offer enhanced rigidity and better flushing capabilities, making them suitable for demanding applications, while round rods are a cost-effective and compatible option for standard drilling equipment.

Difference Between Surface Mining and Underground Mining

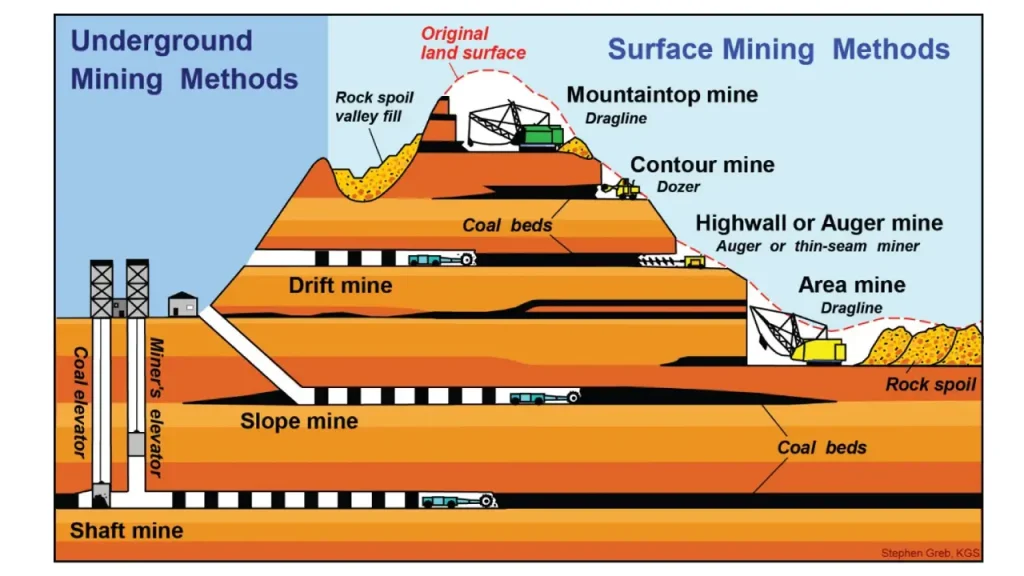

Surface mining and underground mining are two distinct methods for extracting minerals, each with its own advantages and disadvantages. The primary difference lies in the location of the extraction. Surface mining involves removing the earth’s surface (overburden) to access mineral deposits that are close to the ground. In contrast, underground mining requires creating a network of shafts and tunnels to reach deeper deposits.

- Location: Surface mining extracts minerals near the surface, while underground mining is used for deposits deep within the Earth.

- Cost and Efficiency: Surface mining is generally more cost-effective and productive due to the use of large machinery and simpler logistics. Underground mining is more expensive and complex because of the need for specialized equipment, ventilation systems, and extensive infrastructure.

- Environmental Impact: Surface mining can have a greater impact on the landscape, causing significant land disruption. Underground mining has a smaller surface footprint but can pose risks to ground stability and groundwater systems.

- Safety: Surface mining is generally considered safer for workers as it avoids the risks associated with confined spaces, rock falls, and gas buildups inherent in underground operations.

Underground Mining Methods

Underground mining methods are generally categorized into three classes based on the level of support required: unsupported, supported, and caving methods. These techniques are chosen based on the geology, rock strength, and geometry of the ore body.

- Room-and-pillar mining: This method is used for flat-lying deposits like coal or salt. It involves creating a series of interconnected tunnels (“rooms”) while leaving pillars of the ore body in a systematic pattern to support the mine’s roof.

- Longwall mining: Primarily used for coal, this highly efficient method involves a cutting machine that moves along a long face of the coal seam. Hydraulic supports hold up the roof while the coal is extracted, allowing the roof to collapse behind the mining face.

- Cut-and-fill mining: This technique is used for steeply inclined or narrow deposits. As horizontal slices of the ore are excavated, the resulting void is immediately filled with waste rock or other materials to provide support for the walls.

- Block caving: This is a large-scale, low-cost method for massive, weak ore bodies. It involves undercutting a large block of ore from below, causing it to cave under its own weight into a series of chutes, where it can then be collected.

Pros and Cons of an Underground Mining

Underground mining, which is used to extract minerals deep beneath the earth’s surface, offers both advantages and disadvantages.

Pros:

- Reduced surface disturbance: Because most of the activity is below ground, it leaves the natural landscape and ecosystems above largely intact.

- Higher-grade ore: It targets specific, high-yield deposits, resulting in more efficient extraction with less waste.

- Access to valuable resources: It allows for the extraction of minerals that are too deep to be reached by surface mining methods.

- Lower noise and visual impact: Much of the machinery and operations are underground, which reduces noise pollution and leaves the land’s natural appearance largely unchanged.

Cons:

- Higher costs: The complexity of digging deep underground, installing ventilation systems, and maintaining safety equipment significantly increases operational expenses.

- Higher safety risks: It is historically more dangerous due to risks like cave-ins, explosions, and exposure to toxic gases.

- Environmental risks: While it has less surface impact, it can cause problems like subsidence (ground collapse), and has the potential to contaminate groundwater.

- Longer development time: Extensive planning and infrastructure setup are required, which means it takes longer before production can begin.

Underground Mining Environmental Impact

Underground mining has a significant, though often less visible, impact on the environment compared to surface mining. While it minimizes surface land disruption, it can cause problems beneath the ground that affect the surface.

- Groundwater Contamination: Chemicals and heavy metals can leach from the mine into underground water sources, polluting aquifers and nearby surface water bodies.

- Subsidence: The removal of material underground can cause the ground above to sink or collapse, leading to sinkholes and damage to buildings and infrastructure.

- Air Pollution: Although dust levels are generally lower than in surface mines, underground mines can release gases like methane, which is a potent greenhouse gas, and dust particles that can cause health problems.

- Waste Disposal: The waste rock, known as tailings, brought to the surface can be toxic or radioactive and requires careful management to prevent environmental harm.

Conclusion

Throughout this guide, we have explored the intricate world of underground mining, highlighting the innovative methods and technologies that make it a cornerstone of modern industry. We’ve seen how advancements in automation, data analysis, and safety systems are transforming the profession, ensuring both efficiency and the well-being of the workforce. The future of mining lies in continued innovation and a commitment to sustainable practices.

The journey into the Earth’s depths requires a deep understanding of geological challenges and engineering solutions. The information presented here serves as a vital resource for anyone looking to navigate the complexities of this industry, from planning and development to day-to-day operations. The insights shared are designed to help you appreciate the precision and skill involved in extracting the resources that power our world.

For all your operational needs, ensure you are equipped with the best tools available. You can find wholesale underground mining drill bits and rods from our partners at Sinodrills. Their high-quality products are engineered for durability and performance, helping you to achieve maximum productivity and efficiency in all your drilling activities.