A drill bit cone is a critical component in roller cone drill bits used for rock and mineral drilling. It rotates to crush, cut, and grind rock efficiently, making it essential for mining, construction, and oilfield applications. Understanding its structure and function ensures optimal drilling performance and longevity.

There are different types of drill bit cones, including single, double, and triple cones, each designed for specific rock conditions. Their teeth or inserts, material, and rotation mechanism determine cutting efficiency. This guide will help you choose the right drill bit cone for your project, improving speed, accuracy, and cost-effectiveness.

What is Drill Bit Cone?

A drill bit cone is the rotating part of a roller cone drill bit that crushes, cuts, and grinds rock during drilling.

Each cone is fitted with teeth or tungsten carbide inserts and spins independently on bearings, converting rotary motion into effective rock-breaking action. Drill bit cones come in single, double, or triple configurations, tailored for different rock types and drilling conditions.

Cone Type Drill Bits

Cone type drill bits are essential tools in rock drilling, designed to crush, grind, and break rock efficiently. They come in single, double, and tricone configurations, each tailored for specific rock conditions and drilling requirements. Understanding their features and applications helps optimize drilling performance and reduce operational costs.

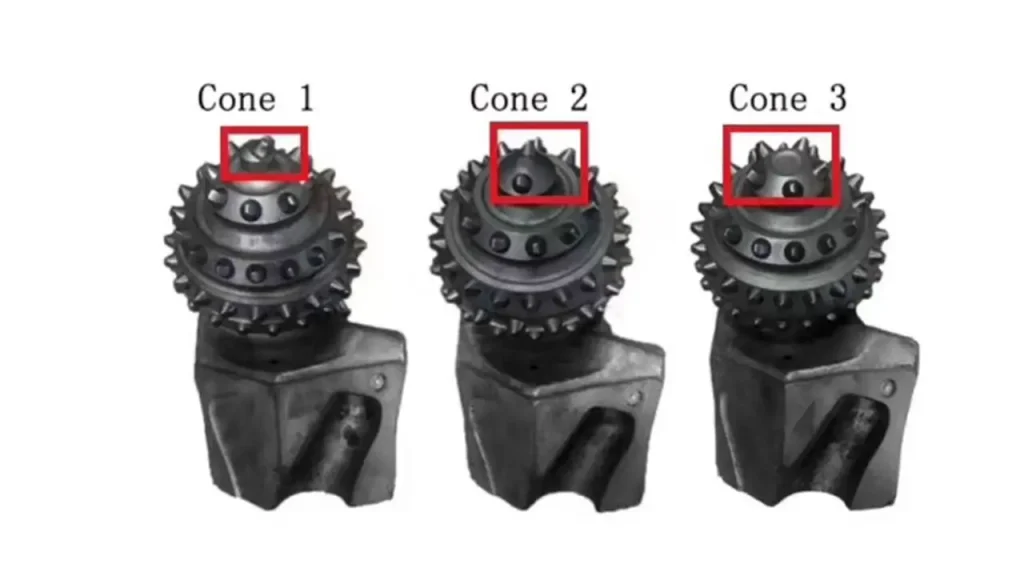

Single Cone Drill Bits

Single cone drill bits feature one rotating cone with teeth or carbide inserts that crush and grind rock. They are simple in design, easy to maintain, and ideal for soft to medium rock formations, providing steady drilling performance for small- to medium-scale projects.

These drill bits are efficient in uniform rock conditions and are cost-effective for short-term operations. While they drill slower in hard rock, their straightforward structure ensures minimal downtime and easy replacement of worn teeth, making them a practical choice for lighter drilling tasks.

Two Cone Drill Bits

Two cone drill bits, also called double cone bits, have dual rotating cones that provide balanced wear and faster penetration. They are suitable for medium to hard rock, offering stability and better distribution of cutting forces during drilling operations.

The dual cones reduce vibration and improve drilling accuracy, extending the life of the bit. Maintenance is slightly more complex than single cone bits, but their enhanced efficiency and ability to handle tougher formations make them ideal for industrial drilling projects.

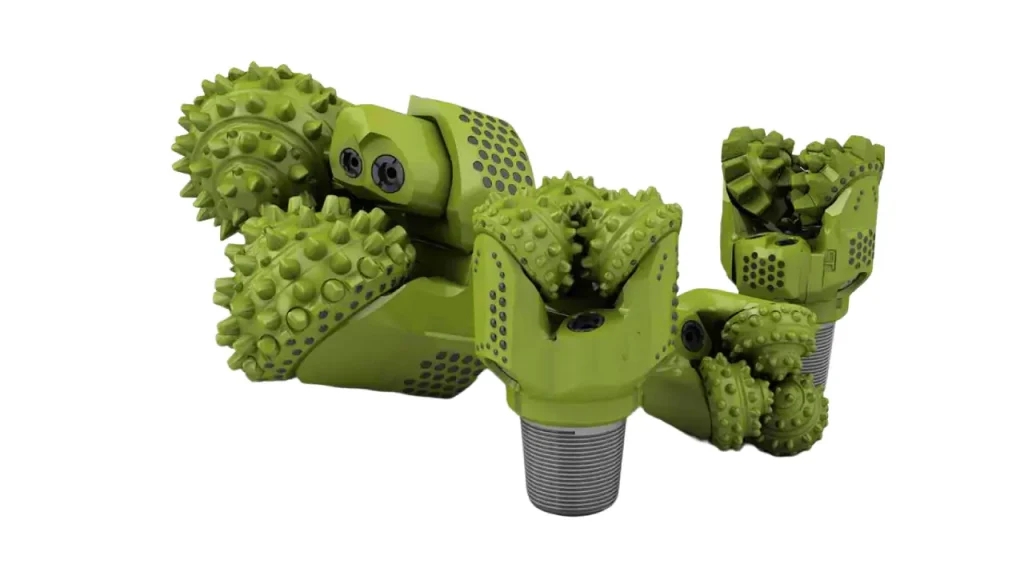

Tricone Drill Bits

Tricone drill bits consist of three rotating cones with precisely arranged teeth, allowing for high-speed drilling in hard, abrasive, or mixed rock formations. They are the most versatile and widely used type of roller cone bits.

These bits provide superior stability, uniform wear, and effective rock fragmentation. Their design ensures smooth rotation, reduced vibration, and faster drilling rates, making them suitable for large-scale mining, oil, and construction projects where efficiency and durability are critical.

Comparison Table of Cone Type Drill Bits

| Feature | Single Cone Drill Bit | Two Cone Drill Bit | Tricone Drill Bit |

|---|---|---|---|

| Cone Count | 1 | 2 | 3 |

| Rock Type | Soft to medium | Medium to hard | Soft to very hard |

| Drilling Speed | Moderate | Faster | Fastest |

| Stability | Low | Medium | High |

| Wear Distribution | Uneven | More even | Uniform |

| Maintenance | Simple | Moderate | Complex |

| Applications | Small- to medium-scale projects | Industrial drilling | Large-scale mining, oil, construction |

Rock Drill Bit Cone Shape

A rock drill bit’s cone shape is a defining characteristic of roller cone bits, which are widely used in drilling boreholes for oil and gas exploration, mining, and water wells. This design allows the bit to efficiently crush and shear rock formations.

Key Features of Rock Drill Bit Cone Shape

- Tricone Design: Most modern rock drill bits feature a tricone design, meaning they have three rotating cones. These cones interfit and roll across the bottom of the hole as the bit is rotated, ensuring full bottom-hole coverage and uniform rock destruction. This configuration is essential for maximizing the rate of penetration (ROP) and prolonging the bit’s lifespan in diverse geological environments.

- Cutting Structures: The cones are equipped with cutting structures, which can be milled-tooth or tungsten carbide inserts (TCI). Milled-tooth bits have steel teeth machined directly onto the cone, ideal for softer formations. TCI bits use extremely hard inserts pressed into the cone, offering superior durability and performance in harder, more abrasive rocks.

- Bearing Assembly: Within the cone structure is a sophisticated bearing assembly that allows each cone to rotate independently on the bit body. This critical component must withstand immense axial and radial loads and high temperatures. Modern bearing designs include sealed journal bearings or roller bearings, often employing a system to maintain internal pressure and keep out drilling fluids and abrasive cuttings.

- Nozzle Placement: Strategically placed nozzles are positioned on the bit body, often directing drilling fluid—or mud—towards the cones. The fluid serves multiple vital functions: it cools and lubricates the cones and bearings, effectively clears the crushed rock cuttings from the bottom of the hole, and prevents them from being re-ground by the rotating cones, optimizing drilling efficiency.

Cone Type Drill Bit Benefits

A cone-type drill bit, predominantly a roller cone bit, offers significant benefits in the drilling industry due to its robust and dynamic cutting action. It excels in various formations by crushing and shearing the rock, making it a highly versatile and cost-effective tool for achieving deep penetration in complex geological environments.

Advantages of Cone-Type Drill Bits

- Formation Versatility: Cone bits can be engineered with different cutting structures, such as milled teeth (steel tooth) for softer formations or tungsten carbide inserts (TCI) for hard, abrasive rock. This adaptability means a single bit type can be customized to efficiently drill through varying strata, reducing the need for frequent bit changes.

- Durability and Longevity: The rolling action distributes stress across the cutters, and the incorporation of robust materials like Tungsten Carbide Inserts (TCI) enhances wear resistance. Modern bits feature sealed bearing assemblies and advanced metallurgy, significantly extending the operational life and ensuring longer periods of continuous drilling, which saves substantial rig time.

- High Rate of Penetration (ROP): By utilizing a dynamic crushing and shearing mechanism, cone-type bits effectively fracture and remove rock at the bottom of the borehole. Their tricone design ensures maximum coverage and uniform distribution of weight, leading to a consistently high ROP, accelerating the overall drilling process and lowering operational costs.

- Cost-Effectiveness: Although the initial purchase price might be higher than some fixed-cutter bits, the extended lifespan and superior drilling efficiency of roller cone bits often result in a lower cost per foot drilled. Their ability to handle diverse formations and maintain performance minimizes non-productive time (NPT) associated with equipment failure or change-outs.

How to Choose Cone Type Drill Bits?

Choosing the right cone type drill bit is critical for efficient drilling and equipment longevity. Factors like rock hardness, drilling speed, and project scale determine the most suitable bit. Selecting the correct cone type reduces wear, improves penetration, and ensures cost-effective operations.

- Assess Rock Type: Understand the hardness and abrasiveness of the rock formation. Single cone bits are best for soft rock, two cone bits handle medium rock, and tricone bits excel in hard or mixed formations. Proper matching prevents rapid wear and optimizes drilling efficiency.

- Determine Drilling Speed Needs: Consider project timelines and production goals. Single cone bits drill slower but are cost-effective, two cone bits offer moderate speed, and tricone bits provide fast penetration. Choosing the right speed ensures timely completion while maintaining bit integrity.

- Evaluate Stability Requirements: Drilling stability reduces vibration and improves hole accuracy. Single cone bits provide basic stability, two cone bits offer balanced performance, and tricone bits ensure maximum stability in tough conditions. Stability directly impacts wear distribution and overall drilling quality.

- Consider Maintenance and Cost: Maintenance complexity and cost vary by cone type. Single cone bits are easy to maintain and replace, two cone bits require moderate attention, while tricone bits need more expertise. Factoring these aspects helps balance performance and operational expenses.

Conclusion

Choosing the right drill bit cone is crucial for maximizing drilling efficiency and equipment life. By understanding cone types, teeth design, and suitable rock formations, operators can achieve faster penetration, reduced wear, and lower operational costs. Sinodrills provides a wide range of high-quality cone-type drill bits for wholesale.

Whether you need single, double, or triple cone drill bits, selecting the appropriate cone type can significantly impact drilling performance. Investing in durable, precision-engineered drill bit cones from Sinodrills ensures consistent results across various industrial applications, from mining to construction.

For businesses seeking reliable suppliers, Sinodrills offers wholesale cone-type drill bits tailored to your project needs. Partnering with us guarantees access to top-quality products, technical support, and competitive pricing, helping you optimize drilling operations and achieve long-term success.