Anchor bolt grouting is a crucial process in construction that secures bolts within concrete or masonry structures. By filling gaps and providing strong adhesion, grouting ensures that anchor bolts maintain structural integrity under heavy loads and vibrations. Proper grouting prevents loosening, corrosion, and potential failures over time.

Understanding how anchor bolt grouting works helps engineers, contractors, and project managers ensure safer, longer-lasting installations. It enhances load distribution, strengthens connections, and supports heavy machinery or structural elements. Choosing the right grout material and application method is essential for achieving optimal performance in residential, commercial, and industrial construction projects.

What is Anchor Bolt Grouting?

Anchor bolt grouting is the process of filling the space between an anchor bolt and the surrounding concrete or masonry with a specialized grout material. This ensures a tight, secure fit, prevents movement, and provides a strong bond that can handle heavy loads, vibrations, and dynamic forces in construction.

Grouting also protects anchor bolts from environmental damage, such as corrosion or water infiltration, while distributing stress evenly along the bolt. Proper anchor bolt grouting enhances structural stability, prolongs the lifespan of the installation, and is essential for safely supporting machinery, structural elements, and other critical construction components.

Anchor Bolt Grouting Material

Choosing the right grouting material is essential for securing anchor bolts and ensuring structural stability. Grout fills the gap between bolts and concrete, providing strong adhesion, load distribution, and corrosion protection. The correct material enhances durability, supports heavy loads, and ensures long-term safety in construction, industrial, and infrastructure projects.

- Epoxy Grout – Epoxy grout provides superior bonding strength and chemical resistance. We use it to secure anchor bolts in critical applications, including industrial and heavy machinery installations. Its durability ensures long-lasting performance under high loads, vibrations, and harsh environmental conditions.

- Cementitious Grout – Cement-based grout is versatile, cost-effective, and widely used for anchoring bolts in concrete. We choose this material for general construction applications, offering good compressive strength, ease of use, and compatibility with standard concrete structures while maintaining structural stability.

- Non-Shrink Grout – Non-shrink grout expands slightly as it sets, eliminating gaps between anchor bolts and concrete. We use it to prevent bolt loosening, ensure consistent load transfer, and maintain secure connections in precision-critical installations.

- Polyurethane Grout – Polyurethane grout is flexible, resistant to water, and ideal for damp or chemically aggressive environments. We use it to protect anchor bolts from corrosion and vibration stress while providing secure, long-lasting anchoring in industrial and outdoor applications.

- Hybrid Grout Systems – Hybrid grouts combine properties of cementitious and epoxy materials. We use them for projects that require both high strength and chemical resistance, ensuring anchor bolts remain firmly secured while adapting to challenging construction conditions.

Anchor Bolt Grouting Process

The anchor bolt grouting process ensures secure, durable fastening in concrete or masonry. Proper steps and materials enhance load-bearing capacity, prevent corrosion, and extend the lifespan of installations. Following a systematic process guarantees strong adhesion, accurate placement, and consistent performance, making grouting essential for construction, industrial, and infrastructure projects.

Tools Needed

- Drill with appropriate drill bit

- Cleaning brush or compressed air

- Epoxy or cementitious grout

- Mixing bucket and paddle

- Caulking gun or grout pump

- Protective gloves and safety glasses

Step 1: Prepare the Hole

Before grouting, the drilled hole must be clean and free of debris. We use brushes and compressed air to remove dust, concrete chips, and moisture. A clean surface ensures proper adhesion between the anchor bolt and grout, preventing weak bonding or voids that could compromise structural stability.

Proper preparation also involves checking hole depth and diameter against anchor specifications. Ensuring accurate dimensions helps the bolt fit correctly and allows grout to fully surround the bolt. Consistent preparation reduces installation errors, increases load-bearing capacity, and enhances long-term durability for all concrete and masonry projects.

Step 2: Mix the Grout

We thoroughly mix the chosen grout according to manufacturer’s instructions. Proper consistency is critical for easy application, maximum bonding strength, and void-free filling around the anchor bolt. Over- or under-mixing can reduce performance and compromise the stability of the installation.

Accurate mixing also ensures uniform curing and chemical reaction. Consistent grout properties distribute stress evenly along the bolt and concrete interface. Properly mixed grout enhances durability, resists shrinkage or cracking, and provides a reliable foundation for supporting structural or machinery loads over time.

Step 3: Insert the Anchor Bolt

The anchor bolt is carefully inserted into the grouted hole, ensuring it remains vertical and correctly aligned. We rotate or lightly tap the bolt to eliminate air pockets and guarantee complete contact between grout and the bolt surface.

Correct placement ensures the anchor bolt achieves maximum load-bearing capacity. Proper alignment prevents uneven stress distribution, enhances structural stability, and reduces the risk of loosening or failure under dynamic and static loads, maintaining long-term reliability in construction or industrial applications.

Step 4: Cure the Grout

After installation, the grout must cure for the recommended period. We protect the area from movement, moisture, or temperature extremes to ensure full strength development and chemical bonding around the anchor bolt.

Curing ensures the anchor bolt achieves its designed load capacity and durability. Proper curing prevents shrinkage, cracking, or weak adhesion. Following manufacturer guidelines and environmental considerations guarantees reliable, long-lasting performance, maintaining safety and stability in both residential and industrial projects.

Self-Drilling Anchor Bolts for Grouting

Self drilling anchor bolts are designed to simplify installation and ensure secure fastening in concrete or masonry during grouting applications. By combining drilling and anchoring functions, these bolts reduce labor, improve alignment, and provide strong adhesion. Their efficiency and reliability make them ideal for construction, industrial, and infrastructure projects requiring durable and safe installations.

- Easy Installation – Self drilling anchor bolts eliminate the need for pre-drilled holes. We use their integrated drilling tip to secure bolts directly into concrete or masonry, reducing installation time, labor costs, and human error while ensuring precise placement and strong, consistent bonding.

- Strong Load-Bearing Capacity – These bolts provide high strength for supporting heavy structural components. We design them to distribute loads evenly, resist vibration, and maintain stability, ensuring long-term reliability in construction projects, industrial machinery installation, and infrastructure applications where safety and performance are critical.

- Compatibility with Grouting – Self drilling anchor bolts work seamlessly with epoxy or cementitious grouts. We ensure proper grout bonding around the bolt for enhanced adhesion, corrosion resistance, and load distribution, resulting in secure, long-lasting installations in both indoor and outdoor environments.

- Time and Cost Efficiency – Using self drilling anchor bolts reduces project timelines and labor requirements. We offer high-quality products that combine drilling, anchoring, and grouting compatibility, providing contractors and engineers with a reliable, cost-effective solution for fast, durable, and safe installations.

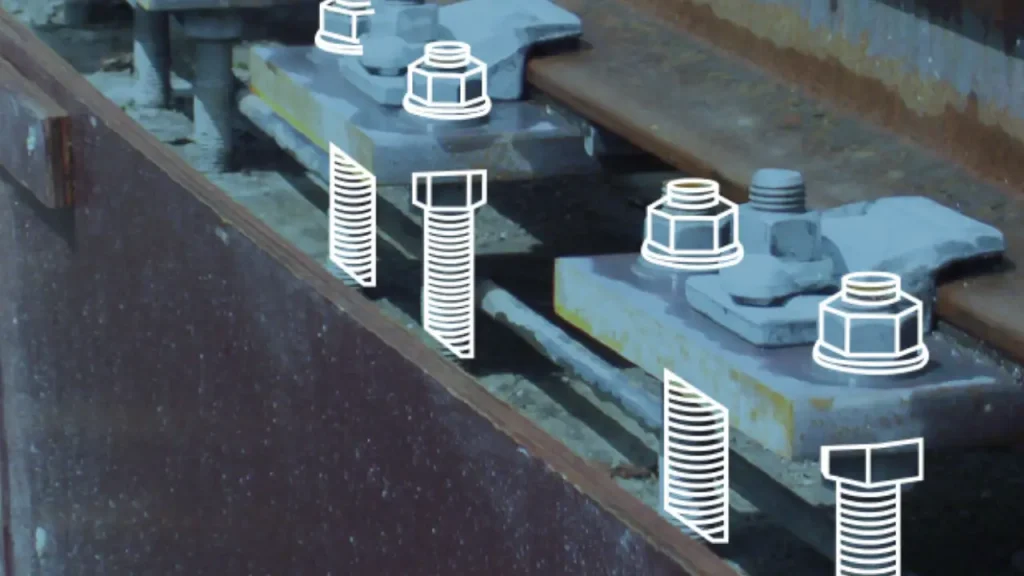

Anchor Bolt Grouting Applications

Anchor bolt grouting applications play a vital role in ensuring secure, stable, and long-lasting structural connections. This process strengthens anchor bolts by filling surrounding voids, preventing movement, and improving load transfer efficiency. It is widely used across construction, industrial installations, and heavy machinery foundations where precision and durability are essential for long-term performance and safety.

- Structural Steel Base Plates – Grouting anchor bolts under steel base plates helps maintain exact alignment while increasing load-bearing stability. The grout fills microscopic gaps beneath the plate, preventing rocking and distributing loads evenly. This enhances the structural integrity of buildings, bridges, and towers exposed to constant stress, vibration, and environmental changes.

- Industrial Machinery Installation – Heavy machines require perfectly stable anchoring, and grouted anchor bolts prevent vibration-induced loosening. By creating a solid bond between bolts and concrete, grouting ensures accurate machine positioning. This minimizes maintenance downtime, enhances productivity, and extends equipment lifespan, especially in factories, processing plants, and manufacturing lines.

- Precast Concrete Components – Grouted anchor bolts secure precast walls, beams, and columns during assembly, improving overall connection strength. The grout compensates for placement tolerances and ensures each anchor transfers loads properly. This increases structural reliability, accelerates installation timelines, and reduces safety risks associated with misalignment or shifting during construction.

- Infrastructure and Utility Projects – Anchor bolt grouting is widely used in installing guardrails, light poles, traffic signals, and utility supports. The grout stabilizes bolts against wind loads, vibration, and soil settlement. This provides long-term durability in demanding outdoor environments, ensuring essential public infrastructure stays secure and performs safely throughout its service life.

Conclusion

Proper anchor bolt grouting is vital for safe and durable structural connections. It ensures stability, prevents movement, and extends the life of concrete or masonry installations. Neglecting grouting can lead to bolt failure, safety hazards, and costly repairs. Prioritizing correct grout materials and methods guarantees stronger, more reliable anchoring for any construction project.

Anchor bolt grouting not only strengthens connections but also supports heavy equipment and structural components under dynamic and static loads. By understanding its importance, construction teams can prevent premature wear, corrosion, and structural failures. Implementing high-quality grouting practices ensures long-term performance, efficiency, and safety in industrial, commercial, and residential projects.

For your construction and industrial needs, get wholesale self-drilling anchor bolts from our Sinodrills. We provide durable, high-strength bolts designed for optimal performance with proper grouting. Our products ensure secure installations, superior bonding, and long-term reliability. Trust Sinodrills to supply anchor bolts that meet your project requirements and exceed safety and quality standard