Custom Carbide Button Bit Manufacturer in China

Our carbide button bits deliver exceptional drilling performance and longevity. Featuring premium tungsten carbide inserts, they ensure efficient penetration in various rock formations. Engineered for durability and wear resistance, these bits maximize productivity and reduce downtime. Available in multiple sizes and designs to suit your specific drilling needs.

Sinodrills - Your Trusted Carbide Button Bit Manufacturer from China

As a trusted carbide button bit manufacturer from China, Sinodrills delivers reliable and high-performance drilling solutions. 1 Our bits are crafted with premium materials and advanced technology, ensuring efficient rock penetration and extended service life. We offer a diverse range of button bits to meet various drilling needs in mining, quarrying, and construction. Partner with Sinodrills for quality and cost-effectiveness.

Various Carbide Button Bit

tungsten carbide button bits

Our tungsten carbide button bits offer superior hardness and wear resistance for demanding drilling operations. Manufactured with premium tungsten carbide inserts, they ensure efficient rock fracturing and a longer lifespan compared to standard bits. Our range includes various sizes and button configurations to optimize performance in diverse geological conditions. Choose our reliable bits for enhanced productivity and reduced drilling costs.

sintered carbide buttons for rock drill mining

Our YG6 grade sintered carbide buttons for rock drill mining deliver reliable performance in demanding conditions. Crafted with a specific tungsten carbide and cobalt composition, these buttons offer a good balance of wear resistance and toughness, ideal for medium-hard rock formations. We ensure consistent quality for efficient and cost-effective drilling operations.

carbide button bits rock drilling tools

We offer high-performance carbide button bits, essential rock drilling tools engineered for efficiency and durability. Featuring robust tungsten carbide buttons, our bits ensure optimal penetration rates and extended lifespan in diverse rock formations. Designed to withstand demanding drilling conditions, they deliver reliable performance, increasing productivity and reducing operational costs. Explore our range for your specific drilling applications.

carbide DTH button bits

We offer carbide DTH (Down-The-Hole) button bits engineered for powerful and efficient drilling. Featuring robust tungsten carbide buttons, our bits deliver superior penetration rates and extended wear life in demanding rock conditions. Designed for optimal air flushing and stability, they ensure maximum performance and productivity for your DTH drilling operations. 3 Explore our range of sizes and configurations.

carbide tapered button bits

We offer a comprehensive selection of carbide tapered button bits, engineered for efficient and reliable drilling in demanding applications. Featuring robust tungsten carbide buttons, these bits provide excellent wear resistance and penetration rates in various rock types. Their tapered design ensures a secure and effective connection with drill rods, maximizing energy transfer and productivity. Available in multiple sizes and taper angles to suit your specific drilling requirements.

carbide conical button bits designed for efficient rock drilling

We offer carbide conical button bits expertly engineered for efficient rock drilling. Their unique conical design ensures optimal rock fracturing and penetration rates in demanding applications. Manufactured with high-quality carbide, these bits provide exceptional wear resistance and durability, leading to increased productivity and reduced operational costs. Explore our range of sizes to find the perfect match for your drilling needs.

tricone button drill bits

We offer high-performance tricone button drill bits designed for superior drilling efficiency in various rock formations. Our bits feature advanced cutting structures and durable tungsten carbide buttons, ensuring extended bit life and reduced drilling costs. We provide a range of sizes and configurations to meet your specific drilling needs.

retrac semi-ballistic button drill bits

We offer a wide range of retrac semi-ballistic button drill bits. These high-performance tools are engineered for efficiency and durability in medium to hard rock formations. The retractable skirt design and semi-ballistic carbide buttons ensure superior drilling performance, straighter holes, and easy retrieval in challenging conditions.

flat face DTH button drill bits

We offer flat face DTH button drill bits for superior performance. These bits feature a robust design with high-quality tungsten carbide inserts, ensuring efficient drilling and extended service life. Ideal for a wide range of rock formations, they deliver excellent penetration rates and hole straightness. Our bits are compatible with various DTH hammers, providing reliable results.

polycrystalline diamond carbide insert PDC button bit

We offer polycrystalline diamond carbide insert PDC button bits, which combine the hardness of synthetic diamond with the toughness of a tungsten carbide substrate. Ideal for DTH, RC, and top hammer bits, these tools provide superior wear resistance and a longer lifespan for geological exploration, mining, and stone quarrying.

thread carbide DTH PDC button bits

We offer premium carbide DTH, PDC, and button bits for drilling applications. Our range includes thread bits for percussive drilling, carbide bits for enhanced durability, and PDC bits for fast, efficient soft-to-medium formation drilling. We provide custom solutions to meet specific drilling needs, ensuring superior performance and reliability.

Customize Your Desired Carbide Button Bit

Button Configuration and Size:

Tailor the bit’s performance to your specific rock conditions by selecting the optimal button arrangement (e.g., domed, ballistic, conical) and size. Larger buttons offer increased wear resistance in abrasive formations, while smaller, more aggressive buttons enhance penetration in harder rock. The density and pattern of the buttons directly influence drilling speed, stability, and hole cleaning efficiency. Carefully consider the balance between penetration rate and bit lifespan based on your project requirements.

Bit Body Design and Flushing Holes

Customize the bit body for optimal strength and efficient cuttings removal. Different body shapes and steel grades offer varying levels of durability and resistance to wear and tear. The number, size, and placement of flushing holes are crucial for effectively removing drilling debris, preventing clogging, and ensuring consistent performance. Consider the type of drilling fluid and the volume required to maintain optimal hole cleaning in your specific application.

Carbide Grade and Quality

Select the appropriate tungsten carbide grade to match the abrasiveness and hardness of the rock you’ll be drilling. Different carbide grades offer varying levels of hardness, toughness, and wear resistance. Choosing a higher-quality carbide ensures extended bit life and reduces the frequency of replacements, ultimately lowering operational costs. Partnering with a reputable manufacturer who utilizes premium raw materials is essential for achieving consistent and reliable performance.

Shank Type and Thread Connection

Ensure seamless integration with your drilling equipment by specifying the correct shank type (e.g., tapered, threaded) and thread connection. Matching the bit’s connection to your drill string is critical for efficient power transfer and preventing premature wear or failure. Consider the torque and rotational speed of your drilling rig to select a shank and thread that can withstand the operational demands. Precision machining and adherence to industry standards are vital for a secure and reliable connection.

what are Carbide Button Bits?

Carbide button bits are essential tools in various drilling applications, particularly for penetrating hard rock formations. They consist of a steel body embedded with tungsten carbide buttons, which serve as the cutting elements.

Tungsten carbide is an exceptionally hard and wear-resistant material, allowing these bits to effectively fracture and crush rock. The strategic arrangement and design of the carbide buttons on the bit face optimize drilling efficiency and the lifespan of the tool.

what are Carbide Button Bits used for?

Carbide button bits are primarily used for drilling through hard and abrasive rock formations in various industries. Their robust construction and tungsten carbide inserts enable them to effectively fracture and remove rock, making them essential tools for creating boreholes and breaking ground.

These carbide button bits offer superior wear resistance and longevity compared to traditional steel bits, leading to increased efficiency and reduced operational costs in demanding drilling environments.

Here are some specific applications of carbide button bits:

- Mining: Used for exploration drilling, production drilling (creating blast holes), and tunneling in various types of ore and rock.

- Quarrying: Employed to drill blast holes for extracting stone, granite, limestone, and other materials from quarries.

- Construction: Utilized for foundation drilling, anchoring, piling, and other ground preparation tasks, as well as drilling through concrete and reinforced concrete.

- Water Well Drilling: Essential for creating boreholes to access underground water resources in different geological formations.

- Geothermal Drilling: Used in the process of drilling wells to tap into geothermal energy sources.

- Oil and Gas Drilling: Applied in certain stages of well drilling, particularly in harder rock layers.

- Road Construction: Used for drilling blast holes in rock for road excavation and construction.

what are Carbide Button Bits made of?

Carbide button bits are primarily made of two key components: a steel body and tungsten carbide buttons (also known as inserts). The steel body provides the structural integrity and connects the bit to the drilling equipment.

It is typically made from high-quality alloy steel that can withstand the stresses and impacts of drilling. The body is machined to hold the carbide buttons securely in a specific arrangement.

The cutting elements are the tungsten carbide buttons. Tungsten carbide is a composite material made by combining tungsten and carbon atoms, often with a metallic binder such as cobalt or nickel.

This material is renowned for its exceptional hardness, wear resistance, and ability to retain a sharp cutting edge even under demanding conditions. The specific grade of tungsten carbide used can vary depending on the intended application and the hardness of the rock being drilled, with different compositions offering varying levels of toughness and abrasion resistance.

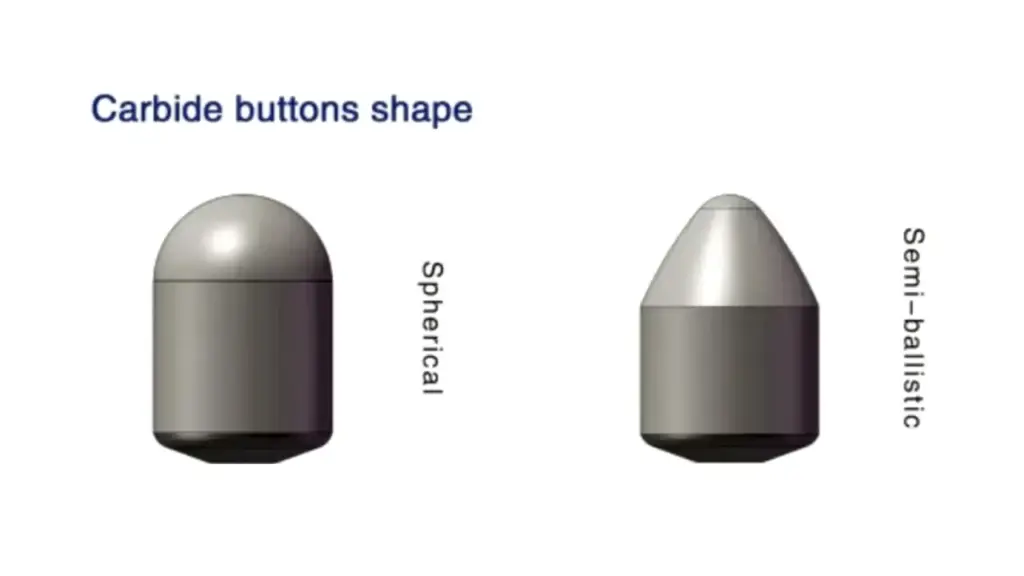

Carbide bit shapes

The shape of carbide buttons used in drilling tools, such as button bits, plays a significant role in their performance and efficiency. There are two common shapes: Spherical and Semi-ballistic. Each shape is designed to optimize drilling in different rock formations, enhancing penetration rates and overall durability.

Spherical Carbide Button: This shape is ideal for softer rock formations where a smoother, more consistent penetration is required. The spherical shape helps in providing even wear and better contact with the rock surface.

Semi-ballistic Carbide Button: Designed for harder and more abrasive rock formations, the semi-ballistic shape provides enhanced resistance and helps break through tough materials with greater efficiency. The pointed design improves the cutting action, making it suitable for more challenging geological conditions.

Each button shape is strategically chosen based on the specific drilling needs and rock hardness, ensuring that the drilling operation is as efficient and cost-effective as possible.

Send Your Inquiry Now

All-in-one Carbide Button Bit Solutions for Your Project

Simplify your drilling with our all-in-one carbide button bit solutions. We offer a comprehensive range of high-performance bits tailored to your specific project needs. From various button configurations and body designs to premium carbide grades, we provide everything you need for efficient and reliable rock drilling. Maximize productivity and minimize downtime with our durable and application-specific solutions. Partner with us for a seamless drilling experience.