Casing While Drilling (CWD) has become a truly transformative technology, providing a streamlined, integrated approach that addresses many traditional drilling challenges head-on. This innovative approach allows us to run casing while drilling, effectively integrating two distinct operations into one seamless process.

This blog post will delve into the core benefits of Casing While Drilling, explore specific applications where it really excels, and look to the future of this transformative technology while working to improve overall well construction efficiency and safety.

What is Casing While Drilling?

Casing While Drilling (CWD) is an innovative well construction technique where the casing string itself functions as the drill string. This means that instead of performing drilling and casing operations as separate, sequential steps, they are integrated and executed simultaneously.

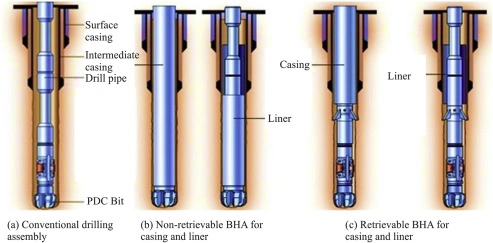

A drill bit is attached directly to the casing shoe, or a retrievable bottom-hole assembly (BHA) drills ahead, while drilling fluid circulates through the casing and returns via the annulus. This method fundamentally streamlines the well construction process, aiming to enhance efficiency, improve wellbore stability, and reduce overall drilling time and costs.

How Does CWD Work?

When we talk about casing while drilling, we are referring to an advanced technology where the casing string itself acts as the drill string. This innovative method allows us to run casing while drilling a portion of the well, without the need to trip the drill string separately. The mechanism involves either attaching a specialized drill bit directly to the casing shoe or using a retrievable bottom hole assembly to drill forward.

The drilling fluid circulates in the casing, exits through the drill bit, and returns to the surface through the annulus between the casing and the wellbore. This integrated process combines two different operations into one seamless process, fundamentally changing the way wells are constructed and representing a major leap forward in casing while drilling technology.

Types of Casing While Drilling

Casing while drilling is a technique that simultaneously drills and cases the well, offering significant time and cost savings. Here are the general types of casing used in drilling operations

Surface Casing

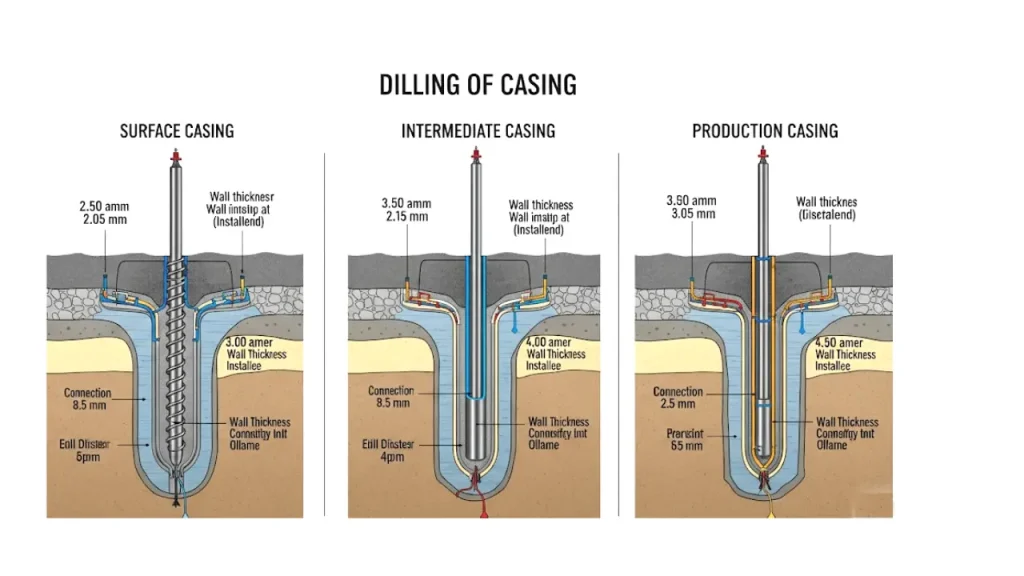

Surface Casing is typically the first and largest diameter casing string set in a well using the Casing While Drilling (CwD) method. Its primary purpose is to seal off shallow, unconsolidated formations and protect freshwater aquifers from contamination by drilling fluids. As depicted, it’s drilled into the upper part of the wellbore, often through loose soil or gravel, and then cemented in place. This provides a stable foundation for subsequent drilling operations and prevents the upper sections of the hole from caving in. The CwD technique is particularly effective here, as it minimizes the open-hole time in these unstable zones, enhancing safety and efficiency from the very beginning of well construction.

Intermediate Casing

Intermediate Casing is run after the surface casing and extends deeper into the wellbore. Its main function in Casing While Drilling is to isolate troublesome zones, such as formations with abnormal pressures, lost circulation zones, or volatile rock. By drilling and casing simultaneously, we can quickly seal off these problematic intervals, preventing further complications and improving wellbore integrity.

This allows for the use of different drilling fluid weights in deeper sections without impacting shallower, weaker formations. The image illustrates how this casing string effectively bridges the gap between the surface and the deeper, more challenging geological layers, ensuring a secure path for continued drilling.

Production Casing

Production Casing is the final casing string installed in a well using Casing While Drilling, extending from the surface or a previous casing point down to the target hydrocarbon reservoir. Its critical role is to isolate the productive zones, ensuring that hydrocarbons can be safely and efficiently produced without intermingling with other formation fluids or contaminating the environment.

The CwD method allows for a continuous drilling and casing process right into the reservoir, which can be beneficial in maintaining wellbore stability in complex or depleted pay zones. Once set and cemented, this casing provides the conduit for hydrocarbon flow and supports the well completion equipment, forming the backbone of the producing well.

What Are the Benefits of Casing While Drilling?

Casing While Drilling (CwD) is an advanced technique that revolutionizes well construction by running the casing into the borehole simultaneously with the drilling process. This integrated approach fundamentally improves wellbore stability, safety, and operational efficiency, making it an indispensable method for drilling in challenging, unstable formations.

The significant benefits of Casing While Drilling include:

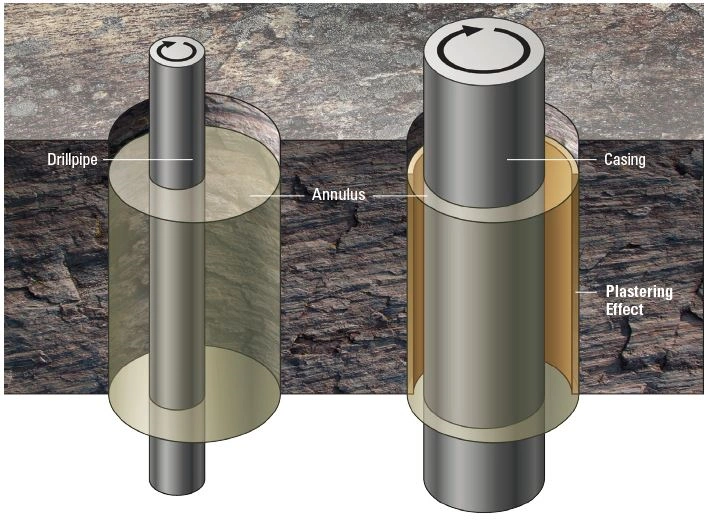

- Improved Wellbore Stability: The immediate placement and rotation of the casing string reinforces the borehole wall as soon as it is drilled. This continuous support, combined with a ‘plastering effect’ from the casing, seals weak, fractured, or unconsolidated zones, virtually eliminating the risk of hole collapse or sloughing shale.

- Significant Time and Cost Reduction: By eliminating the conventional step of tripping the drill string out to run the casing separately, CWD drastically cuts down non-productive time (NPT). Fewer trips mean less wear on equipment and a streamlined process, which ultimately reduces the overall drilling time and the corresponding rig costs.

- Mitigation of Lost Circulation: The simultaneous process, and the smearing of drilled solids into the formation by the rotating casing, creates a thin, strong filter cake. This sealing action effectively plugs permeable or fractured zones, which minimizes the loss of expensive drilling fluids into the formation, preserving the drilling budget.

- Enhanced Rig Floor Safety: CWD technology greatly reduces the need for manual handling of conventional drill pipe connections and other tools. Fewer pipe trips and a simplified process minimize personnel exposure to heavy machinery and high-risk operations, contributing to a safer, more efficient working environment.

Casing While Drilling Disadvantages

While casing while drilling offers numerous advantages, it’s also important to acknowledge its inherent challenges and disadvantages. These aspects require careful consideration during planning and execution.

One primary concern is the limited steerability and directional control compared to conventional drilling, as the larger casing string can restrict precise well path adjustments. We also often encounter higher annular pressure losses (APL) and equivalent circulating densities (ECD) due to the tighter annulus, which can increase the risk of fracturing weaker formations.

Applications of Casing While Drilling

We have implemented Casing While Drilling systems in a variety of environments and have found several scenarios where the technology truly stands out, providing a powerful solution to persistent drilling challenges. From highly unstable formations to demanding offshore operations, Casing While Drilling systems consistently prove their value by increasing efficiency and reducing risk.

Drilling in Unstable Formations and Depleted Zones

One of the areas where casing while drilling in challenging formations truly shines is when we’re drilling through highly unstable or unconsolidated formations. The immediate casing support prevents wellbore collapse, which is a common and costly issue in such environments.

By continuously supporting the wellbore, we avoid the risks associated with open-hole exposure. Similarly, in depleted zones where differential sticking is a significant concern, the continuous support offered by the casing significantly mitigates this risk, allowing us to drill more efficiently and safely through these tricky sections without losing valuable drilling time.

Offshore and Deepwater Drilling Advantages

The benefits of casing while drilling for offshore operations are particularly pronounced. In deepwater drilling, where rig time is extremely expensive, CwD’s ability to reduce the number of tripping operations leads to substantial time and cost savings.

The enhanced wellbore stability it provides is critical in these challenging environments where well control and integrity are paramount. We’ve seen how CwD can simplify complex well designs and improve the overall efficiency and safety of our offshore projects, making it a preferred method for such demanding conditions.

Mitigating Lost Circulation and Well Control Issues

Casing while drilling to prevent lost circulation is another critical application where this technique excels. When we encounter highly permeable or fractured formations, traditional drilling methods can lead to significant fluid losses, impacting drilling efficiency and increasing costs. With CwD, the casing is immediately set, effectively sealing off these problematic zones and preventing or minimizing lost circulation.

This also contributes to better well control, as we’re less likely to experience unexpected influxes when the wellbore is continuously supported by casing, providing a more stable and predictable drilling environment.

Conclusion

In conclusion, Casing While Drilling (CwD) is a transformative technology that merges two critical operations—drilling and casing—into a single, highly efficient process. It offers dramatic improvements in wellbore integrity by providing immediate support to the open hole, thus mitigating risks like collapse, sloughing, and lost circulation which plague conventional drilling methods. This technique is especially valuable in unstable or challenging geological formations.

The key competitive advantage of adopting CwD lies in the significant reduction of non-productive time (NPT) and overall project costs. Eliminating the need for separate trips to pull the drill string and run the casing streamlines operations, while the enhanced stability often allows for deeper casing setting depths. This superior performance translates directly into faster well delivery and improved economic returns.

To integrate the efficiency of CwD into your operations, start with reliable, high-quality tools. Get in touch with Sinodrills today for wholesale pricing on drill bits, retractable systems, and drill rods. Equip your rig for maximum performance and cost savings! Contact Sinodrills now!