Custom Chevron Drag Bit Manufacturer in China

We offer high-performance chevron drag bits, engineered for optimal stability and efficient drilling in unconsolidated to semi-consolidated formations. Featuring a distinctive V-shaped blade design, our chevron bits excel at maintaining a straight hole and ensuring excellent cuttings evacuation. Ideal for soft to medium shales, limestones, and sandstones, they provide superior penetration rates and extended durability. Choose our reliable Chevron Drag Bits for your demanding drilling projects.

Sinodrills - Your Trusted Chevron Drag Bit Manufacturer from China

Sinodrills is your trusted Chevron Drag Bit manufacturer from China, renowned for producing high-quality and reliable drilling tools. Our chevron bits are specifically designed for optimal stability and efficient performance in semi-consolidated and abrasive formations. We leverage advanced manufacturing techniques and premium materials to ensure superior penetration rates and extended durability, making Sinodrills your ideal partner for robust drilling solutions.

Various Chevron Drag Bit

3 wing chevron drag bit

We provide premium 3-wing chevron drag bits, engineered for exceptional stability and drilling efficiency. Their distinct three-blade V-shaped design ensures superior cutting action and excellent hole straightness in diverse formations, from soft shales to consolidated sandstones. Ideal for challenging conditions where maintaining hole integrity is critical, our 3-wing chevron bits offer enhanced durability and optimal penetration rates for your drilling projects.

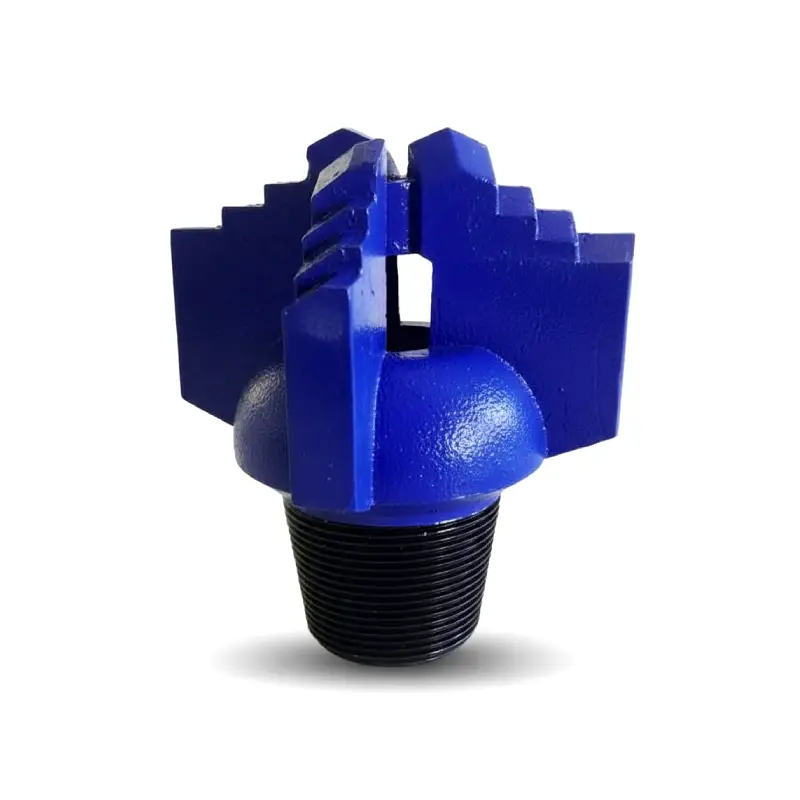

4 wing chevron drag bit

We provide robust 4-wing chevron drag bits, engineered for exceptional stability and aggressive drilling in challenging soft to medium-hard formations. The four-wing design enhances bit stability and optimizes cuttings removal, preventing “bit balling.” Ideal for shales, limestone, and consolidated clays, our bits deliver superior penetration rates and extended operational life, ensuring efficiency and cost-effectiveness for your drilling projects.

chevron type pDC drag bits with 3 wings for oil gas wells

We provide chevron type PDC drag bits with 3 wings specifically engineered for optimal performance in oil and gas wells. These bits combine the stable, V-shaped cutting structure of chevron designs with the aggressive, long-lasting performance of Polycrystalline Diamond Compact (PDC) cutters. Ideal for drilling through soft to medium-hard formations encountered in oil and gas exploration, our 3-wing PDC drag bits offer superior penetration rates and enhanced durability, contributing to significant efficiency gains in your drilling operations.

chevron drag bit for rock drilling

We offer robust Chevron Drag Bits specifically designed for drilling in rock formations, particularly those classified as medium to hard. While drag bits are generally for softer materials, our chevron designs, often featuring durable tungsten carbide inserts, are engineered to handle more consolidated formations like hard shales, limestones, and tougher gravels. These bits provide enhanced stability and a more aggressive cutting action, making them a suitable choice for challenging rock drilling applications where other drag bits might fail.

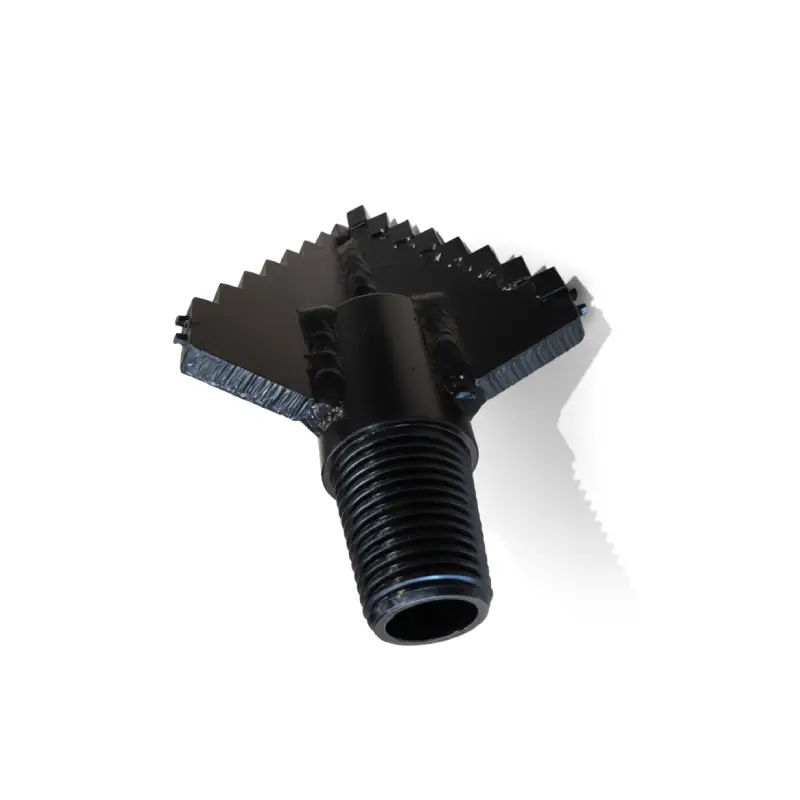

chevron drag bit for rock drilling

We offer a robust tungsten carbide drag drill bit, engineered for exceptional performance in various drilling applications. Its sharp, multi-pronged design, visible in the image, ensures efficient material removal and durability. The threaded connection guarantees secure attachment, making it a reliable tool for professional use. This bit is designed for longevity and superior cutting power.

3 wing face carbide drag drill bit

We offer a high-performance 3-wing face carbide drag drill bit, engineered for exceptional drilling efficiency and durability. Its advanced design features a three-wing cutting face and premium carbide inserts, ensuring superior penetration rates and extended bit life in various rock formations. Ideal for demanding drilling applications.

heavy duty step drag drill bit

This step drill bit is a heavy-duty, versatile tool for drilling and reaming. Its unique drag design allows for precise hole sizing in various materials, including steel, aluminum, and plastics. The single cutting edge reduces heat buildup, extending the bit’s life. Ideal for metalworkers and DIY enthusiasts.

three-wing drag bits for water well drilling

We provide three-wing drag bits designed for efficient water well drilling. These bits deliver consistent performance and durability, helping to achieve faster penetration in various soil and rock conditions. Ideal for both shallow and deep wells, our three-wing drag bits are built to meet the demands of professional drilling operations, ensuring reliable results every time.

3 wing carbide tipped chevron drag bit

We supply 3-wing carbide-tipped chevron drag bits designed for efficient rock and soil drilling. These bits provide excellent durability and consistent performance in demanding drilling conditions. Ideal for construction, mining, and infrastructure projects, our chevron drag bits ensure smooth penetration and reliable results, helping you complete your drilling tasks faster and more effectively.

3 wing step face carbide drag bit

We provide 3 wing step face carbide drag bits designed for efficient drilling in various rock formations. Our drag bits deliver consistent performance, durability, and precision, ensuring smooth operation in demanding drilling projects. Ideal for mining, construction, and infrastructure applications, these bits help improve drilling efficiency while reducing downtime and maintenance needs.

4 blade chevron drag drill bit

We offer 4-blade Chevron Drag Drill Bits, engineered for superior rock drilling performance. Designed for precise cutting and efficient material removal, these bits ensure longer service life and reduced wear. Ideal for various geological formations, our chevron drag bits provide consistent penetration, enhanced stability, and reliable results for demanding drilling operations.

customized chevron drag drill bit

We offer customized chevron drag drill bits, engineered for superior rock penetration and long-lasting performance. Our bits provide precise cutting, enhanced stability, and optimized wear resistance, suitable for various geological conditions. Designed for efficiency and reliability, these chevron drag bits help maximize drilling productivity, reduce downtime, and deliver consistent, high-quality results on every project.

API chevron drag drill bit

We offer API chevron drag drill bits, engineered for superior rock cutting and long-lasting performance. Designed for precision and efficiency, these bits ensure smooth penetration, reduced wear, and reliable results in various drilling conditions. Ideal for professional applications, our API chevron drag drill bits deliver consistent productivity while minimizing downtime and maintenance needs.

Customize Your Desired Chevron Drag Bit

Bit Diameter and Connection Type

We provide Chevron Drag Bits in a wide array of diameters, ensuring the precise hole size for your application. Furthermore, we can accommodate various industry-standard connection types (e.g., API Regular, API Internal Flush, specific proprietary threads) to guarantee seamless compatibility with your existing drill string and rig setup. This precision fit minimizes operational delays and maximizes drilling efficiency.

Blade Angle and Number of Blades

The chevron’s “V” angle and the total number of blades significantly influence cutting aggressiveness and stability. We can customize these features to optimize performance for your specific rock hardness and formation type. For instance, a sharper angle might be better for harder shales, while a wider angle could suit softer, more abrasive formations, ensuring efficient material removal and stable drilling.

Tungsten Carbide Insert (TCI) Grade and Placement

The durability and cutting ability of your Chevron Drag Bit heavily rely on its tungsten carbide inserts. We offer various TCI grades, from those suited for abrasive yet soft rock to those designed for maximum impact resistance in harder, fractured formations. We also customize their strategic placement on the blades to enhance wear life and optimize cutting efficiency for your target geology.

Junk Slot and Waterway Optimization

Efficient cuttings evacuation is critical for maintaining high penetration rates and preventing bit balling, especially in challenging rock. We can customize the size and geometry of the junk slots to ensure rapid removal of debris. Additionally, the internal waterway design can be optimized to match your specific drilling fluid (water, mud, or air) and pump capacity, ensuring excellent bit cleaning and preventing regrinding.

what is a chevron drag bit?

A chevron drag bit is a type of drill bit characterized by its distinctive V-shaped or “chevron” pattern of cutting blades. These fixed blades, typically tipped with tungsten carbide inserts, are designed to scrape and shear through formations.

The chevron configuration provides excellent stability during drilling, helping to maintain a straight hole, and its geometry often facilitates efficient flushing of cuttings due to optimized waterway designs.

They are particularly effective in unconsolidated to semi-consolidated formations, including soft to medium shales, limestones, and some sandstones, where their robust design offers both good penetration rates and durability.

chevron drag bit benefits

Chevron drag bits offer several key benefits that make them a preferred choice for specific drilling applications:

- Enhanced Hole Stability: The V-shaped blade design provides superior stability during drilling, helping to maintain a straighter borehole and reducing deviations, which is crucial for project accuracy.

- Efficient Cuttings Evacuation: Their optimized waterway and junk slot designs facilitate excellent flushing of drilled material, minimizing the risk of bit balling and re-grinding of cuttings, leading to higher penetration rates.

- Versatility in Formations: While ideal for soft to medium formations like shales and limestones, the robust design and often tungsten carbide inserts allow them to perform effectively even in some harder, semi-consolidated rock types.

- Durability and Longevity: The sturdy construction and strategic placement of wear-resistant materials contribute to an extended bit life, reducing the frequency of bit changes and overall operational downtime.

- Good Penetration Rates: By efficiently shearing and scraping the formation while clearing cuttings, chevron drag bits can achieve competitive penetration rates in suitable ground conditions.

chevron drag bit applications

Chevron drag bits are highly versatile and find extensive use in various drilling applications where soft to medium-hard, consolidated to semi-consolidated formations are encountered. Their unique design offers both stability and efficient material removal.

Common applications include:

- Water Well Drilling: Ideal for drilling through varying soil strata, soft shales, and consolidated sands commonly found in water well projects, providing stable and efficient hole creation.

- Geothermal Drilling: Often used in shallow to medium depth geothermal projects that penetrate soft to medium-hard rock formations, benefiting from their stability and durability.

- Mineral Exploration: Employed for coring or pilot holes in exploration programs that involve unconsolidated overburden or soft mineralized zones, offering good sample recovery and penetration.

- Environmental Drilling: Suitable for site investigations, monitoring well installations, and remediation efforts in diverse soil and soft rock conditions, where precise hole integrity is important.

- Construction and Foundation Drilling: Used for drilling anchor holes, pile holes, and other foundational work in less consolidated ground conditions, where a stable and clean hole is required.

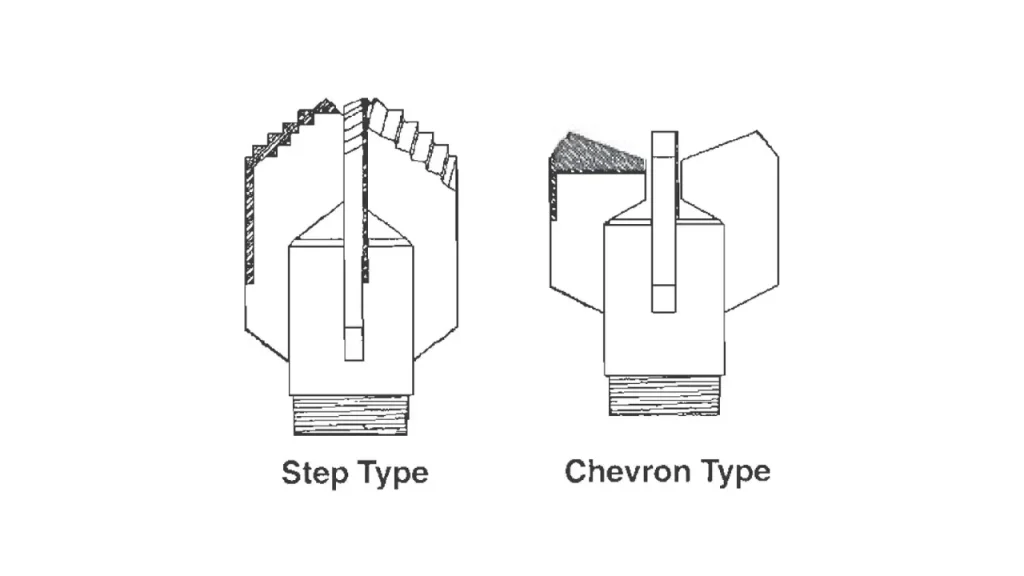

chevron drag bit vs step

When choosing between chevron and stepped drag bits, the primary distinctions lie in their cutting action, stability, and optimal application for different formation types. Both are excellent drag bit choices, but excel in different scenarios.

Here are the differences between chevron drag bits and stepped drag bits in the following:

Chevron Drag Bits:

- Cutting Action: They tend to have a more aggressive, V-shaped shearing action, providing excellent stability and maintaining a straighter hole. The cutters are typically spread out more.

- Optimal Formations: Best suited for unconsolidated to semi-consolidated formations, including soft to medium shales, limestones, and sandstones. They handle formations that might cause bit wandering well.

- Cuttings Removal: Often feature larger junk slots and optimized waterway designs for efficient flushing of cuttings, especially beneficial when drilling with air or in sticky formations prone to balling.

- Stability: Known for superior hole straightness and stability due to their balanced cutting forces.

- Cutting Action: Characterized by multiple “steps” on their blades, creating a series of individual cutting edges. This design provides a more aggressive, yet controlled, chipping and shearing action.

- Optimal Formations: Highly effective in very soft to medium formations, such as clays, soft shales, and unconsolidated sands. The steps help prevent bit balling in sticky materials.

- Cuttings Removal: Their stepped profile is excellent at breaking up and evacuating cuttings efficiently, reducing the likelihood of bit balling in cohesive formations.

- Penetration Rate: Often deliver very high penetration rates in the formations they are designed for, as each step can engage the formation effectively.

Send Your Inquiry Now

All-in-one Chevron Drag Bit Solutions for Your Project

We provide all-in-one Chevron Drag Bit Solutions precisely engineered for your project’s demands. Our expertise covers customizing blade angles, number of wings, and specialized TCI grades for optimal performance in soft to medium-hard formations. Experience superior hole stability, efficient cuttings removal, and enhanced durability. Partner with us for tailored Chevron Drag Bits that guarantee maximum drilling efficiency and project success.