The world of drilling relies on precision and standardization to ensure safety and efficiency. This is particularly true for diamond core drilling, a specialized method used for mineral exploration and geotechnical investigation. Understanding the key players and their roles is crucial for anyone involved in the industry.

One of the most important entities in this field is the Diamond Core Drilling Manufacturers Association, commonly known as DCDMA. This organization plays a vital, yet often unheralded, role in shaping the industry by establishing technical specifications and standards that guide the production of drilling equipment.

What is DCDMA?

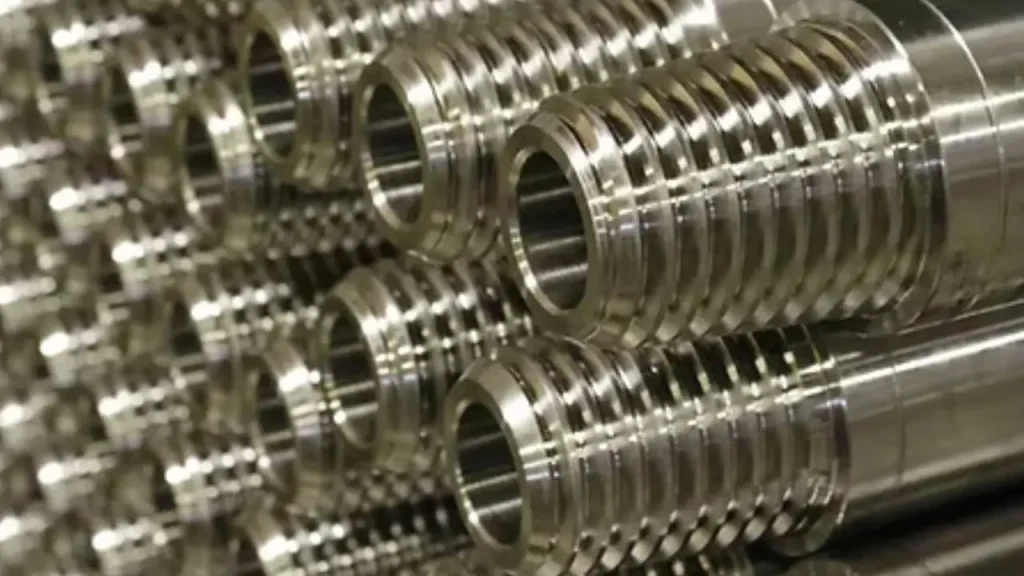

DCDMA stands for the Diamond Core Drilling Manufacturers Association, an organization that has been instrumental in standardizing equipment for the drilling industry. The association’s primary function is to establish and maintain technical specifications for diamond core drilling tools, including drill rods, core barrels, and bits.

These standards ensure that products from different manufacturers are interchangeable, which is crucial for drilling contractors who often need to replace parts in the field. By setting specific dimensions and quality benchmarks, the DCDMA helps to promote safety, efficiency, and reliability in a wide range of drilling applications, from mineral exploration to geotechnical surveying.

DCDMA Drill Rod

DCDMA stands for the Diamond Core Drilling Manufacturers Association, an organization that standardizes drill rod specifications. These standards ensure compatibility and consistent quality across the industry. A DCDMA-compliant drill rod refers to a rod manufactured to these specific dimensions and material grades, which is crucial for safety and efficiency in core drilling projects.

- DCDMA ‘A’ Series: This is one of the smaller standardized series. It’s typically used for relatively shallow holes or in applications where a smaller core sample is sufficient. The ‘A’ series is suitable for jobs that require a more lightweight and maneuverable drill string.

- DCDMA ‘B’ Series: The ‘B’ series drill rods are a step up in size from the ‘A’ series. They are a common choice for various core drilling projects, offering a good balance between core size and drilling depth capability. The ‘B’ series is widely used in mineral exploration.

- DCDMA ‘N’ Series: This is a very popular and widely used series in the drilling industry. The ‘N’ series provides a larger core diameter, making it ideal for detailed geological analysis. Its robust design allows for deeper drilling and is favored for complex exploration projects.

- DCDMA ‘H’ Series: The ‘H’ series is designed for deep drilling and challenging ground conditions. With a larger diameter and greater strength, these rods can handle higher torsional stress and deeper holes. They are a go-to choice for major mining and geotechnical investigations.

- DCDMA ‘P’ Series: The ‘P’ series represents the largest of the standard DCDMA sizes. These rods are used for the deepest and most demanding drilling operations. The large core diameter provides a maximum amount of sample material for comprehensive analysis in large-scale projects.

What is Diamond Core Drilling Used For?

Recommended Drill Rods

Diamond core drilling is a versatile and precise method used to create clean, circular holes in hard materials. This technique is widely employed across various industries, from construction and civil engineering to mineral exploration. It is particularly valued for its ability to produce accurate cuts with minimal damage to the surrounding material.

- Mineral Exploration: Geologists and mining companies use diamond core drilling to extract cylindrical core samples from the earth’s crust. These samples provide a continuous, high-quality record of the subsurface rock, which is crucial for analyzing mineral content, geological structure, and the economic viability of a potential mine site.

- Construction and Civil Engineering: In construction, this method is essential for creating clean openings in concrete, asphalt, and masonry. Applications include drilling holes for plumbing, electrical wiring, HVAC ducts, and anchor bolts. Its non-percussive nature prevents structural damage, making it ideal for both new builds and renovation projects.

- Geotechnical Investigation: Engineers utilize diamond core drilling to assess the strength and composition of soil and rock for major infrastructure projects. By retrieving core samples, they can evaluate ground conditions to design stable foundations for buildings, bridges, and dams, ensuring the long-term integrity and safety of the structures.

DCDMA Specifications for Manufacturers

The Diamond Core Drilling Manufacturers Association (DCDMA) sets essential technical specifications for equipment used in the drilling industry, ensuring interchangeability and safety. These standards are critical for manufacturers of drill rods, core barrels, and bits.

- Drill Rod Diameter and Size Series: Manufacturers must adhere to the standardized rod diameters, such as the widely accepted ‘W’ series (e.g., AW, BW, NW, HQ). This standardization is vital for ensuring that drill rods from different suppliers can be interchanged safely and efficiently in the field during operations, improving drilling logistics.

- Thread Configuration and Compatibility: Specifications mandate precise thread dimensions and forms (like square or tapered threads) for drill rods and couplings. This strict control guarantees secure and correct mating between components from all DCDMA-compliant producers, which is paramount for deep drilling strength and preventing tool failure.

- Material and Strength Requirements: DCDMA outlines specific requirements for the material grade of components, often demanding high-carbon, cold-drawn seamless steel tubing. These requirements ensure superior tensile strength, toughness, and wear resistance, which are essential for the equipment’s durability under extreme drilling stress and harsh geological conditions.

Conclusion

In conclusion, understanding the DCDMA and its role in the drilling industry is essential for anyone seeking reliable and compatible equipment. The standards set by the association are the backbone of quality control and interoperability, ensuring that drill rods, core bits, and other tools from various manufacturers can work together seamlessly.

By adhering to DCDMA specifications, you are not just purchasing a piece of equipment; you are investing in a system that has been proven to be safe and effective. These standards reduce the risk of on-site failures, save valuable time, and ultimately lead to more successful and profitable drilling operations.

For all your drilling needs, we encourage you to explore our DCDMA-compliant wholesale drilling tools from Sinodrills. Our products are manufactured to the highest industry standards, ensuring you receive reliable, high-performance equipment for your next project.