Drilling a deep rock well is a significant investment, and one of the most common questions that arises is: how deep should it be? The answer isn’t always straightforward, as it depends on a complex interplay of geological conditions, water demand, and regulatory requirements. Understanding these factors is crucial for a successful and sustainable water source.

This guide will explore the key considerations in determining the optimal depth for your deep rock well. We’ll delve into the influence of local hydrogeology, the characteristics of your desired water usage, and the importance of adhering to regional drilling guidelines to ensure a reliable and long-lasting water supply.

How Deep Should a Well Be Drilled?

Drilling a deep water well is a specialized process that involves significant planning and the use of heavy machinery. The primary goal is to reach an aquifer—a saturated underground layer of rock or sediment that can yield usable quantities of water—while ensuring the well remains stable and the water supply is clean. The method chosen largely depends on the local geology and the intended depth.

The drilling process typically involves several key stages, from preparing the site to developing the well for optimal water flow. This ensures the well is not only productive but also safe and long-lasting, providing a reliable water source for various needs.

Site Selection and Preparation:

- A suitable location is chosen, considering factors like geological conditions, accessibility for drilling equipment, and proximity to potential contamination sources (e.g., septic systems, fuel tanks).

- Local regulations and permits are secured, and the site is leveled and prepared to accommodate the drilling rig and associated equipment.

Drilling the Borehole:

- Specialized drilling rigs, such as rotary or air rotary, are used to penetrate the ground.

- As the drill bit cuts through rock and soil, drilling fluid (often mud or compressed air) is circulated down the drill string to cool the bit, lubricate it, and carry rock cuttings to the surface.

- The drilling depth is continuously monitored, with adjustments made to speed and pressure based on the encountered geological formations.

Casing and Screen Installation:

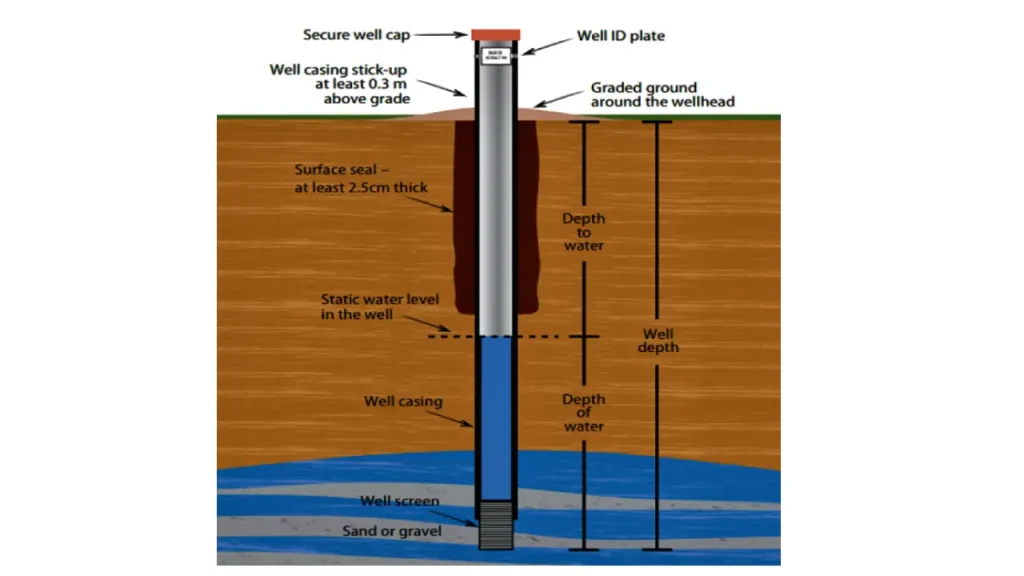

- Once the desired depth is reached and a water-bearing aquifer is identified, a well casing (usually steel or PVC pipe) is lowered into the borehole to prevent collapse and isolate the water supply from shallower, potentially contaminated layers.

- A well screen, a section of the casing with slots or perforations, is placed at the aquifer level, allowing water to enter the well while filtering out sand and sediment.

- Grout is then pumped into the annular space (the gap between the casing and the borehole wall) to create a sanitary seal, further preventing surface contaminants from entering the well.

Well Development and Testing:

- After casing and screen installation, the well is “developed” to remove fine particles and improve the flow of water into the well. This can involve methods like surging, pumping, or airlifting to clear the well screen and surrounding aquifer.

- Finally, the well undergoes testing to determine its yield (how much water it can produce over time) and the quality of the water, ensuring it meets standards for its intended use.

Deep Well Drilling Cost

The cost of deep well drilling is influenced by a multitude of factors, making it challenging to provide a universal estimate. These variables are intricately linked to the geological characteristics of the site, the desired well specifications, and the logistical complexities involved in the drilling operation. Understanding these elements is crucial for accurate budgeting and project planning.

- Well Depth: This is perhaps the most significant factor. Deeper wells require more drilling time, specialized equipment, increased labor hours, and a greater quantity of casing material, all of which contribute to higher costs.

- Geological Conditions: The type of soil and rock formations encountered profoundly impacts drilling difficulty and speed. Drilling through hard rock, dense clay, or complex geological layers demands more powerful machinery, specialized drill bits, and can significantly increase labor time, driving up expenses.

- Well Diameter and Casing Material: Larger diameter wells require more excavation and more material for the casing, which is used to line the borehole and prevent collapse. The type of casing (e.g., PVC, steel) also affects costs, with steel being more durable but also more expensive.

- Drilling Method: Different drilling methods (e.g., rotary, cable tool, air hammer) are suited for various geological conditions. The chosen method influences the type of equipment needed, operational efficiency, and overall cost.

- Location and Accessibility: Drilling in remote or hard-to-access areas incurs higher transportation costs for equipment and personnel. Urban areas might have additional permitting fees and stricter regulations, further impacting the budget.

- Pump System and Components: The cost of the pump system (submersible for deep wells, jet for shallower) and other components like pressure tanks, electrical connections, and water treatment systems can add substantially to the total expense.

- Permits and Regulations: Obtaining necessary permits and adhering to local and national regulations (e.g., environmental assessments, water quality testing) can involve significant fees and additional procedural costs. In Japan, for example, obtaining permits for well drilling is a required step, and costs vary based on the specific location and project complexity.

- Water Quality and Treatment: If the drilled water requires treatment for contaminants or specific mineral content to be suitable for its intended use, the cost of filtration systems, softeners, or other treatment units will add to the overall investment.

- Labor Costs: The wages of skilled drilling operators and support staff contribute significantly to the project cost, with labor rates varying by region.

How to Drill a Deep Well?

Drilling a deep well is a complex process requiring specialized knowledge and equipment. It involves carefully planning and executing several stages to access underground water sources for various needs, from domestic to agricultural use.

Step 1: Site Assessment and Planning

Before any drilling begins, a thorough site assessment is crucial. This involves hydrogeological surveys to identify potential aquifers, considering geological formations, and assessing water quantity and quality.

Obtain all necessary permits and adhere to local regulations, which can vary significantly even within Japan. Proper planning at this stage minimizes risks and ensures the well meets your specific water demands.

Step 2: Preparing the Drilling Site

Once the site is chosen, prepare the area to accommodate the drilling rig and support equipment. This includes leveling the ground, creating access roads, and establishing a safe working environment.

Ensure that sufficient space is available for equipment setup, material storage, and personnel movement. This preparation is vital for operational efficiency and safety throughout the drilling process.

Step 3: Drilling the Borehole

The actual drilling commences using specialized rigs, such as rotary or air rotary, depending on the geology. The drill bit penetrates the Earth, creating a borehole to the targeted aquifer depth.

As drilling progresses, drilling fluid or air is circulated to cool the bit, lubricate the drill string, and effectively remove rock cuttings from the borehole, maintaining a clear path.

Step 4: Installing Well Casing and Screen

Upon reaching the desired depth and a productive aquifer, well casing is installed into the borehole. This casing prevents the well from collapsing and isolates the water-bearing zone from shallower layers.

A well screen, strategically placed within the casing at the aquifer level, allows water to enter the well while keeping out sand and other sediment, ensuring clean water flow.

Step 5: Grouting the Annular Space

After the casing is set, grout is pumped into the annular space—the gap between the well casing and the borehole wall. This creates a sanitary seal, preventing surface water and contaminants from entering the well.

This crucial step protects the groundwater from pollution and ensures the long-term integrity of the well. Proper grouting is essential for maintaining water quality and safety.

Step 6: Well Development

Well development is performed to remove fine sediments and improve the flow of water into the well. This process typically involves surging, pumping, or airlifting to clear the well screen and the surrounding aquifer.

Effective well development increases the well’s efficiency and yield, ensuring a consistent and ample water supply for its intended purpose. It also helps in prolonging the well’s lifespan.

Step 7: Pump Installation and Testing

Finally, a pump system suitable for the well’s depth and expected yield is installed. This includes the submersible pump, pressure tank, and necessary electrical connections to deliver water to your desired location.

The well then undergoes rigorous testing to verify its yield, water quality, and the overall functionality of the pumping system. This final step confirms the well’s readiness for use.

Deep Water Well Drilling Rig

A deep water well drilling rig is a powerful and specialized piece of machinery designed to bore deep into the Earth to access underground aquifers. These rigs vary significantly in size, capability, and the drilling method they employ, depending on the geological conditions, the desired depth of the well, and its intended purpose (e.g., domestic, agricultural, or industrial water supply).

From compact, truck-mounted units to massive, crawler-mounted systems, each rig is equipped with specific components to penetrate various types of rock and soil formations efficiently.

The choice of drilling rig is critical for a successful deep well project, influencing drilling speed, cost, and the overall quality of the well. Modern rigs often incorporate advanced technologies for precision control, real-time data monitoring, and enhanced safety during operation.

- Rotary Drilling Rigs: These are among the most common types for deep water wells. They use a rotating drill bit to cut and grind through rock and soil. Drilling fluid (mud or air) is circulated to cool the bit, lubricate it, and carry cuttings to the surface.

- Cable Tool Drilling Rigs: Historically significant, these rigs use a heavy drill bit attached to a cable that is repeatedly raised and dropped to pound and break through rock formations. They are slower but can be effective in certain hard rock conditions.

- Air Rotary Rigs: Similar to mud rotary but use compressed air instead of fluid to remove cuttings. This method is often preferred in areas where minimizing contamination is crucial or where rock formations are very hard.

- Truck-Mounted Rigs: Offer high mobility, allowing for quick setup and transfer between sites. They are generally suitable for a wide range of depths and geological conditions.

- Crawler-Mounted Rigs: Equipped with tracks, these rigs provide excellent stability and maneuverability on challenging or uneven terrain, making them ideal for remote or difficult-to-access drilling locations.

- Top Drive Rigs: A modern rotary drilling system where the rotary power unit is located at the top of the drill string, providing continuous rotation and allowing for more efficient drilling of long sections of pipe.

Water Well Drill Bits

Recommended Water Well Drill Bits

Water well drill bits are the cutting tools at the end of the drill string, crucial for penetrating various geological formations to create a borehole. The type of bit chosen directly impacts drilling efficiency, speed, and the overall cost of the project. Selecting the correct bit depends heavily on the specific rock and soil types expected at different depths, from soft clays to hard, abrasive rock formations.

Modern drill bits are engineered with advanced materials and designs to withstand immense pressure and friction, ensuring longevity and optimal performance during deep well drilling. Their design features, such as cutting structure and material composition, are tailored to maximize penetration rates and maintain borehole integrity across diverse drilling conditions.

- Tricone Roller Bits: These bits have three rotating cones with steel teeth or tungsten carbide inserts. They are highly versatile and widely used for drilling through a broad range of formations, from medium-soft to very hard rock, by crushing and chipping the material.

- PDC (Polycrystalline Diamond Compact) Bits: Featuring synthetic diamond cutters, PDC bits are known for their high durability and fast penetration rates in soft to medium-hard formations like shale, sandstone, and clay. They cut by shearing and are less prone to damage from impact.

- Drag Bits: Designed for softer formations such as sand, clay, and some soft rock, drag bits cut by scraping or shearing. They are often used for drilling pilot holes or in unconsolidated materials.

- DTH (Down-the-Hole) Hammer Bits: These bits are used with a pneumatic hammer that delivers powerful percussive blows directly behind the bit, pulverizing extremely hard and abrasive rock formations like granite and basalt. They are highly effective for deep drilling in challenging conditions.

- Reamer Bits: While not primarily for initial drilling, reamer bits are used to enlarge existing boreholes or to clean and stabilize the well walls after the primary drilling. They are common in sandy soils or clay formations to ensure a straight and stable hole.

Can a Well Be Drilled Deeper?

Yes, in many cases, an existing water well can be drilled deeper. This process, often referred to as well deepening or re-drilling, is typically undertaken when the current well experiences issues such as insufficient water yield, a fluctuating or dropping water table, or a decline in water quality due to contamination in shallower aquifers. Deepening a well aims to access a more reliable and potentially cleaner water source by extending the borehole further into deeper, untapped aquifers.

The decision to deepen a well versus drilling a new one involves evaluating several factors, including the existing well’s condition, the geological characteristics of the site, and the potential costs. Deepening an existing well can often be more cost-effective than drilling a completely new well, as it utilizes the existing infrastructure like the well casing and the wellhead.

However, the success of deepening depends heavily on finding suitable water-bearing formations at greater depths and ensuring the integrity of the existing well structure during the re-drilling process.

Can You Drill an Existing Well Deeper?

Yes, it is often possible to drill an existing well deeper.

This process, known as deepening a well, is typically pursued when the current well’s water supply becomes insufficient, the water table drops, or water quality declines. By extending the borehole further, the aim is to reach deeper, more productive, or cleaner aquifers.

The feasibility and cost-effectiveness of deepening depend on the well’s current condition, the geological formations below, and whether a suitable deeper aquifer exists. While potentially more economical than drilling a new well, it requires careful assessment to ensure the integrity of the existing well structure and the success of accessing a new water source.

How Much Does It Cost to Drill a Deep Well?

The cost of drilling a deep well is highly variable and depends on a complex array of factors, making it difficult to pinpoint an exact figure without a detailed site assessment.

Generally, you can expect the overall expense to encompass not only the drilling itself but also the installation of the well casing, pump system, and any necessary water treatment.

- Depth of the Well: This is the primary driver of cost. Deeper wells require more drilling time, specialized equipment, increased labor, and more casing material.

- Geological Conditions: Drilling through hard rock, dense clay, or complex geological formations is more challenging and expensive than drilling through softer soils.

- Well Diameter and Casing Material: A larger well diameter means more excavated material and a greater quantity of casing, while materials like steel casing are more durable but also costlier than PVC.

- Drilling Method: Different methods (rotary, cable tool, air hammer) have varying equipment requirements, operational efficiencies, and associated costs.

- Location and Accessibility: Remote or difficult-to-access sites increase transportation costs for equipment and personnel. Urban areas may also have additional permitting fees and stricter regulations.

- Pump System and Components: The type and size of the pump (submersible for deep wells, jet for shallower) and other components like pressure tanks, electrical connections, and water treatment systems add to the total.

- Permits and Regulations: Obtaining necessary permits and adhering to local and national regulations (e.g., environmental assessments, water quality testing) can incur significant fees. In Japan, these permits are a required step and can vary in cost.

- Water Quality and Treatment: If the water quality necessitates treatment for contaminants, the cost of filtration systems, softeners, or other purification units will be an additional expense.

Here’s an estimated cost breakdown for deep well drilling, keeping in mind that these are general figures and actual costs can vary significantly based on location (e.g., Japan) and specific project details:

| Item | Estimated Cost Range ($) |

| Drilling (per foot) | $25 – $75 |

| Well Casing (per foot) | $5 – $130 |

| Submersible Pump | $1,000 – $2,500 |

| Pressure Tank | $300 – $2,000 |

| Electrical Connections | $500 – $1,500 |

| Water Treatment System | $500 – $5,000 |

| Permits & Fees | $200 – $3,000 |

| Total (typical range for residential deep well) | $5,000 – $25,000+ |

Deepest Well Ever Drilled on Earth

The deepest well ever drilled on Earth is the Kola Superdeep Borehole (SG-3), located on Russia’s Kola Peninsula near the border with Norway. This ambitious scientific project, initiated by the Soviet Union in 1970, aimed to explore the Earth’s crust as deeply as possible.

After decades of drilling, the borehole reached an astonishing depth of 12,262 meters (40,230 feet) in 1989. Despite its immense depth, the Kola Superdeep Borehole only penetrated about a third of the way through the Baltic Shield, the continental crust in that region, highlighting the vastness of our planet’s interior.

The project ultimately ceased operations in the mid-1990s due to extreme temperatures encountered at depth (reaching 180°C, far exceeding predictions) and a lack of funding after the collapse of the Soviet Union.

Conclusion

Determining the ideal depth for a deep rock well is a complex process, demanding careful consideration of hydrogeology, water usage, and local regulations. A thorough site assessment and professional expertise are invaluable to ensure a sustainable and efficient water supply.

Ultimately, the goal is to balance drilling costs with water availability and quality, creating a long-term solution. Investing in proper planning and execution prevents future issues and maximizes your well’s potential.

For reliable tools to ensure your deep rock well drilling project is a success, you can get wholesale well drilling tools from our Sinodrills.