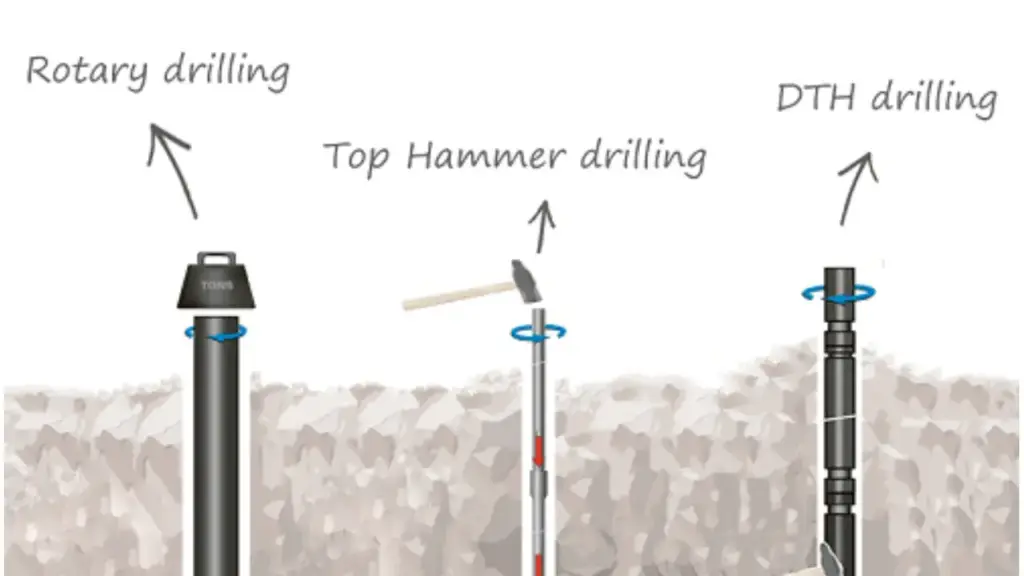

DTH (Down-The-Hole) and rotary drilling represent two primary methods for creating boreholes, each with distinct mechanisms and applications. DTH drilling employs a pneumatically powered hammer located downhole that directly impacts the drill bit to fracture rock. Compressed air not only drives the hammer but also expels the cuttings. This method excels in hard rock and provides efficient, straight holes.

In contrast, rotary drilling utilizes rotational force applied to a drill bit from the surface to grind or cut through the formation. Different types of rotary drilling exist, often employing drilling fluids like mud or air to cool the bit and carry away cuttings. Rotary methods are more versatile across various soil and rock types and are frequently used for deeper drilling and larger diameter holes, offering adaptability based on geological conditions.

What is DTH Drilling

DTH (Down-The-Hole) drilling is a robust and efficient method for creating boreholes, particularly effective in hard rock and challenging geological formations. This technique employs a pneumatic hammer positioned directly behind the drill bit at the bottom of the drill string.

Compressed air, supplied from the surface, powers this hammer to deliver rapid percussive blows to the drill bit, fracturing the rock. Simultaneously, the compressed air also serves to evacuate the resulting rock cuttings and dust from the borehole, ensuring continuous and efficient drilling progress. The direct application of impact force at the drill bit enables DTH drilling to achieve high penetration rates and excellent hole straightness in demanding drilling environments.

What Is Rotary Drilling

Rotary drilling is a method of creating boreholes by using a rotating drill bit to cut or grind through subsurface materials. Unlike DTH drilling which relies on percussive force, rotary drilling applies downward pressure and rotational torque to the drill string, causing the bit to shear, crush, or abrade the rock or soil.

This technique is versatile and can be employed in a wide range of geological formations, from soft soils to hard rock, by selecting the appropriate drill bit and adjusting the drilling parameters. Rotary drilling often utilizes drilling fluids, such as mud or air, to cool the drill bit, lubricate the drilling process, and carry the cuttings away from the bottom of the borehole to the surface.

Difference Between DTH and Rotary Drilling

Understanding the nuances of drilling methodologies is crucial for efficient and effective borehole creation. Down-the-Hole (DTH) and rotary drilling stand out as prominent techniques, each with distinct mechanisms and applications.

Here we delve into the key differences between these methods, providing a comprehensive comparison to aid in selecting the optimal approach for specific drilling projects.

Drilling Speed

DTH drilling generally exhibits a higher penetration rate in hard rock formations. The direct transfer of energy from the hammer, located downhole, to the drill bit results in more efficient rock fracturing. This translates to faster progress, especially when encountering dense, consolidated materials. The percussive action of the DTH hammer pulverizes the rock, allowing for quicker advancement of the borehole compared to the grinding action of rotary drilling in similar conditions.

In contrast, rotary drilling can achieve faster speeds in softer, unconsolidated formations. The continuous rotational force applied by the drill bit efficiently shears through these materials. However, as the hardness of the formation increases, the penetration rate of rotary drilling tends to decrease. The effectiveness of rotary drilling speed is highly dependent on the rock’s compressive strength and the bit’s ability to maintain contact and cutting action.

Drilling Depth

DTH drilling can effectively achieve moderate to deep depths, although its efficiency may decrease significantly in very deep holes due to energy loss in the compressed air over long distances. The need for high-pressure air to power the hammer becomes more demanding as depth increases, requiring larger compressors and potentially limiting the practical depth. However, it is still commonly used for many deep drilling applications.

Rotary drilling is generally more suitable for achieving greater depths. The rotational force is applied from the surface, allowing for more consistent power delivery to the drill bit regardless of the borehole depth. This method is widely employed in deep oil and gas exploration, as well as deep water well drilling, where consistent and reliable drilling is essential.

Hole Diameter

DTH drilling typically creates smaller to medium-sized holes. The size of the hammer and drill bit limits the diameter of the borehole. While larger DTH hammers exist, they require substantial air volume and pressure, which can become challenging to manage. This method is well-suited for applications where precision and a smaller hole diameter are required.

Rotary drilling is capable of producing a wider range of hole diameters, from small to very large. The versatility of rotary drilling bits and equipment allows for greater flexibility in hole size. This makes it suitable for applications such as large-diameter water wells, foundation drilling, and mining operations.

Cost-Efficiency

DTH drilling can be more cost-effective in hard rock formations, especially for smaller to medium-depth projects. The higher penetration rate in these conditions translates to faster project completion, reducing overall labor and rig time. However, the cost of compressed air and the potential need for specialized equipment can increase expenses.

Rotary drilling can be more cost-efficient in softer formations and for larger-diameter or deeper holes. The method’s ability to handle a wider range of conditions and create larger holes can make it a more economical choice for certain projects. However, the slower penetration rate in hard rock can increase the time and cost associated with those projects.

Depth Capabilities

DTH drilling is effective for a wide range of depths, but its efficiency can be limited by the diminishing pressure of compressed air as the hole gets deeper. This can lead to reduced hammer performance and slower penetration rates at greater depths. While deep DTH drilling is possible, it often requires more powerful compressors and careful planning.

Rotary drilling excels in deep drilling scenarios. The transfer of rotational power from the surface remains consistent regardless of depth, making it a preferred method for applications requiring very deep boreholes. This method is widely used in the oil and gas industry, where wells can extend several kilometers into the earth.

Geological Adaptability

DTH drilling is best suited for hard, competent rock formations. The percussive action of the hammer is highly effective at fracturing this type of rock. However, DTH drilling can be less efficient in softer or unconsolidated formations, which can absorb the impact energy and hinder penetration. It can also face challenges in fractured or highly variable formations.

Rotary drilling is more adaptable to a wider range of geological conditions. By selecting the appropriate drill bit and adjusting drilling parameters, rotary drilling can be used in soft soils, unconsolidated sediments, and moderately hard rock. This versatility makes it a popular choice for various drilling applications across diverse geological settings.

Here is a table showing you the main differences between DTH drilling and rotary drilling methods.

| Feature | DTH Drilling | Rotary Drilling |

| Drilling Speed | Higher in hard rock | Faster in soft formations |

| Drilling Depth | Moderate to deep, efficiency decreases at very deep depths | Suitable for greater depths |

| Hole Diameter | Smaller to medium-sized holes | Wide range of hole diameters (small to very large) |

| Cost-Efficiency | Cost-effective in hard rock for smaller to medium depths | Cost-effective in soft formations and for larger/deeper holes |

| Depth Capabilities | Effective for a wide range of depths, but efficiency decreases with depth | Excels in deep drilling scenarios |

| Geological Adaptability | Best suited for hard, competent rock | Adaptable to a wider range of conditions (soft soil to moderately hard rock) |

DTH Drilling and Rotary, Which is Better

Deciding between DTH and rotary drilling hinges on project specifics. DTH often excels in hard rock, delivering faster penetration due to its direct percussive force. However, its efficiency can decrease with depth.

Rotary drilling, conversely, is more versatile across various formations and is generally preferred for deeper and larger-diameter holes.

Ultimately, neither method is universally “better.” The optimal choice depends on these factors:

- Geological conditions: DTH is ideal for hard rock, offering efficient penetration in dense materials, while rotary drilling adapts to a wider range, including softer soils, ensuring versatility across diverse project sites.

- Drilling depth and diameter: Rotary drilling is better suited for deep or large holes, maintaining consistent performance at greater depths, whereas DTH drilling’s effectiveness can be limited by pressure loss in deeper applications.

Conclusion

DTH and rotary drilling represent distinct approaches to borehole creation. DTH excels in hard rock with its percussive hammer action downhole, while rotary drilling utilizes rotational force and downward pressure, often favored in softer formations and larger diameters. Understanding these fundamental differences is crucial for selecting the optimal method based on geological conditions and project requirements.

For those prioritizing efficiency and power in hard rock drilling, DTH tools are the ideal choice. We offer a comprehensive range of wholesale DTH drilling tools designed for durability and performance, ensuring optimal results in demanding applications. Partner with us to access high-quality equipment tailored to your specific drilling needs.

Choosing the right drilling method and sourcing reliable tools are paramount for project success. By considering the strengths of both DTH and rotary drilling and selecting a trusted supplier for your equipment needs, you can maximize efficiency and achieve your drilling objectives effectively. Contact us today for your wholesale DTH drilling tool requirements.