A rock drill bit bearing is a crucial component that supports the bit’s rotation and absorbs the heavy loads during drilling. It ensures smooth operation, reduces friction, and extends the life of the drill bit. Understanding how it works helps operators choose the right bit for their project.

Modern drill bit bearings are engineered to handle extreme pressures and high-speed rotations. Sealed and lubricated, they prevent contamination from dust, mud, and debris while maintaining consistent performance. Proper maintenance and selection of the bearing type can significantly improve drilling efficiency and reduce operational costs.

What is Drill Bit Bearing?

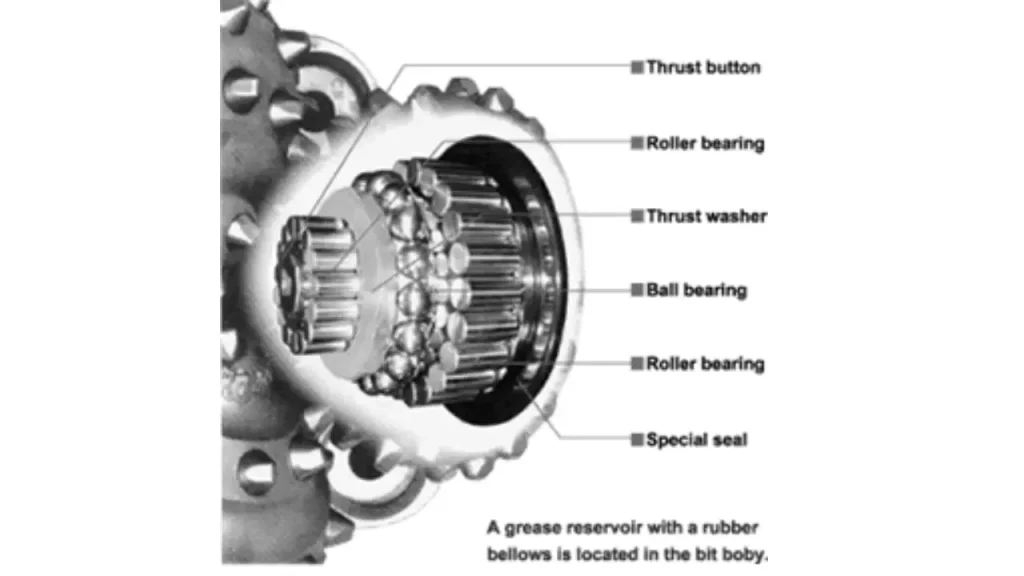

A rock drill bit bearing is a critical component that supports the bit’s rotating cones during drilling. It absorbs heavy loads, reduces friction, and ensures smooth operation in tough rock formations.

Bearings can be sealed or open, protecting against debris and maintaining lubrication, which extends drill bit life and improves drilling efficiency and performance.

How Does Drill Bit Bearing Work?

Drill bit bearings allow the cones of a rock drill bit to rotate smoothly while withstanding heavy loads and high pressure. They reduce friction, prevent overheating, and ensure efficient rock cutting. Proper bearing function is essential for longer bit life and consistent drilling performance.

- Load Support: Bearings absorb axial and radial forces from drilling, protecting the bit structure. This allows the cones to crush and cut rock efficiently, preventing damage to the bit body. Proper load distribution also minimizes stress and extends operational life.

- Friction Reduction: By maintaining a lubricated surface between moving parts, bearings reduce wear and heat generation. This ensures smooth rotation of cones, improves penetration rates, and lowers energy consumption, making drilling faster and more efficient over extended periods.

- Sealing and Protection: Sealed bearings prevent dirt, mud, and rock particles from entering the bearing chamber. This preserves lubrication, prevents premature wear, and maintains consistent performance even in harsh drilling environments, reducing maintenance frequency and downtime.

Types of Drill Bit Sealed with Bearings

Drill bit bearings are what allow the cones on a tricone drill bit to spin smoothly and handle heavy loads during drilling. The type of bearing affects durability, lubrication, and resistance to contaminants, so choosing the right one is key for performance in specific drilling conditions.

- Open Bearings (Non‑Sealed): Basic design without seals, relying on drilling fluid to cool and lubricate the bearings. They are cost‑effective but more prone to contamination and wear, which often shortens service life.

- Sealed Roller Bearings: These feature seals that keep out debris and retain lubricant inside. This reduces friction and enhances lifespan, making them ideal for harsher environments, though they tend to be pricier.

- Sealed Journal Bearings: Using a journal design with sealed lubrication, these bearings support higher loads and resist contamination. They can generate more friction than roller types but offer excellent durability in demanding drilling operations.

- Air‑Cooled Bearings: Designed for air drilling, these use compressed air instead of fluid to cool and clear debris. They’re useful where drilling fluid isn’t available, though air isn’t as effective at cooling as liquid.

How to Choose Suitable Sealed Bearing Drill Bits?

Selecting the right sealed bearing drill bit is essential for efficient drilling and long-lasting performance. Factors like formation type, drilling depth, and operational conditions influence the choice. Choosing properly ensures smooth rotation, reduced wear, and optimal rock penetration in demanding environments.

- Consider Rock Formation Hardness: Soft, medium, and hard rock require different bit designs. Matching the bit to the rock type ensures efficient crushing, minimizes wear, and prevents premature damage to bearings, improving overall drilling performance and reducing downtime.

- Check Bearing Type and Seal Quality: Sealed bearings withstand contamination and maintain lubrication under pressure. Evaluate seal materials and designs to ensure they protect against mud, sand, and debris while supporting smooth rotation over long drilling cycles.

- Evaluate Bit Size and Application: Drill diameter, depth, and intended drilling method determine the suitable bit size and design. Choosing the right size prevents overloading, improves penetration rates, and maximizes the lifespan of the bearing and the drill bit as a whole.

Conclusion

Drill bit bearings play a vital role in the performance and durability of rock drill bits. By supporting the cones and minimizing friction, they ensure smooth rotation and effective rock penetration. Choosing the right bearing type can enhance drilling efficiency and prolong the life of your equipment.

Sealed bearings are especially valuable in harsh drilling environments, protecting against dirt, water, and abrasive particles. They maintain lubrication under high pressure and prevent premature wear, ensuring consistent performance. Using quality bearings reduces maintenance needs and operational downtime, saving time and costs in long-term projects.

For reliable drill bit bearings and wholesale sealed drill bits, Sinodrills offers a wide selection of durable, precision-engineered options. Our products are designed for efficiency, longevity, and tough drilling conditions, helping mining and construction operators achieve optimal performance at competitive prices.