Considering a borehole for your property can be a significant investment, offering a sustainable and independent water supply. However, one of the first questions that comes to mind is often, “How much will it truly cost?”

Understanding the factors that influence borehole drilling expenses is crucial for effective budgeting and decision-making. This guide will break down the various components that contribute to the total cost, helping you gain clarity on your potential investment.

What is Drilling Borehole?

Drilling Borehole is the industrial process of creating a narrow, deep, cylindrical hole, or borehole, into the Earth’s surface using specialized drilling equipment like a drill rig. This fundamental technique is employed across numerous sectors, most commonly to access underground resources such as water (creating a water well), oil, or gas. Boreholes are also crucial for geotechnical investigations to assess soil or rock structure, for installing geothermal energy systems to harness stable subsurface heat, or for environmental monitoring.

The process typically starts with a site assessment to understand the geology and locate the target resource, followed by selecting the appropriate drilling method, such as rotary drilling, which uses a rotating bit cooled by circulating fluids (like water or mud) to cut through the earth and flush cuttings to the surface.

What is a Drilling Borehole Used for?

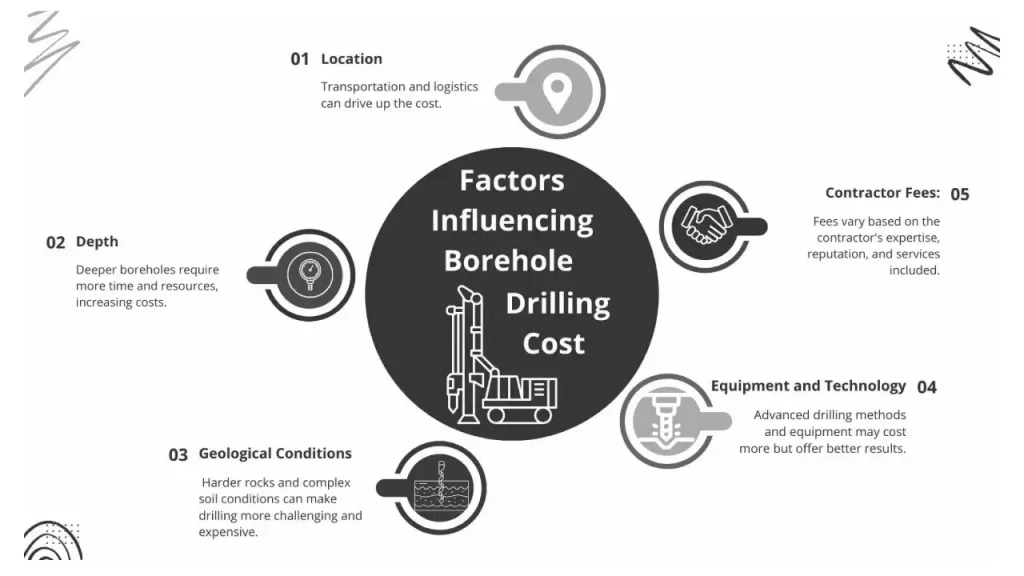

Drilling Borehole Cost Influence Factors

Borehole drilling costs are significantly influenced by geological conditions, with tougher rock formations and complex ground compositions requiring specialized equipment and extended drilling times. The depth and diameter of the borehole also play a major role, as deeper and wider holes necessitate more materials and labor.

Additional factors impacting the overall cost include site accessibility, the chosen drilling method, and the quality of water required, which may involve further testing and treatment. Furthermore, local regulations, permitting fees, and the cost of necessary components like casing and pumping systems contribute to the final price.

- Geological Conditions: Rock type, soil composition, presence of boulders or unstable ground.

- Borehole Dimensions: Depth and diameter of the hole.

- Site Accessibility: Ease of bringing in drilling equipment and personnel.

- Drilling Method: Rotary, percussion, or auger drilling, each with varying costs.

- Water Quality Needs: Requirements for testing and treatment (e.g., for potable water).

- Components and Equipment: Casing material (PVC vs. steel), pump type, filtration systems.

- Permits and Regulations: Local fees and compliance requirements.

- Labor and Transportation: Cost of skilled operators and moving equipment to the site.

How Much Does It Cost to Drill a Borehole

The cost of borehole drilling can vary significantly depending on a multitude of factors, making it challenging to provide a precise universal figure. From the geological conditions of the site to the intended use of the borehole, each element plays a crucial role in determining the final expenditure. Understanding these variables is key to estimating the potential investment for your drilling project.

Additional Costs to Consider

Beyond the direct drilling charges, there are several other potential costs to factor into your budget. These can include geological surveys and site assessments conducted prior to drilling, which help determine the optimal drilling location and method. Permitting and licensing fees, which vary by jurisdiction, are also a necessary expense in many areas.

Well development and testing, crucial for ensuring the borehole’s productivity and water quality (for water wells), add to the overall cost. This can involve pumping tests to determine yield and water quality analysis. The cost of pumping equipment, such as pumps, pressure tanks, and associated plumbing, should also be considered, particularly for water supply boreholes.

Finally, ongoing maintenance and potential future repairs are important long-term considerations. While not part of the initial drilling cost, ensuring the longevity and efficiency of the borehole may require periodic inspections and servicing, which should be budgeted for over the lifespan of the system.

Here’s a general table summarizing estimated borehole drilling costs:

| Factor | Low Estimate ($) | High Estimate ($) | Notes |

| Per Foot/Meter | $15 | $50+ | Varies greatly with depth, diameter, and geological conditions. |

| Mobilization | $500 | $2,000 | Cost to transport equipment to and from the site. |

| Casing per foot | $5 | $20 | Depends on material (PVC, steel) and diameter. |

| Pump System | $1,000 | $5,000+ | For water wells, includes pump, pressure tank, and installation. |

| Permitting | $100 | $1,000 | Varies by location and type of borehole. |

| Well Testing | $300 | $1,000 | For water wells, includes yield testing and water quality analysis. |

| Total Project | $3,000 | $15,000+ | Highly variable; consult with local drillers for accurate quotes. |

Average Cost of Drilling a Borehole

The average cost of drilling a borehole can vary widely, but for a residential water well, a typical range is often cited between $3,000 and $15,000 for a complete system and installation. This broad range accounts for significant differences in project specifics, from the geological conditions at the site to the required depth and diameter of the well. While drilling itself might cost $15 to $65 per foot, this is only one component of the total expenditure.

Several key factors contribute to the overall price. These include:

- The geological conditions of the drilling site: Drilling through soft soil is generally less expensive than penetrating hard rock formations.

- The depth and diameter of the borehole: Deeper and wider boreholes require more time, equipment, and materials, thus increasing costs.

- The intended purpose of the borehole: A domestic water well will have different requirements and associated costs than a borehole for agricultural irrigation, geothermal heating, or environmental monitoring.

- Accessibility of the site: Remote locations or those difficult for heavy machinery to reach may incur additional transportation fees.

- Type of casing and materials used: PVC casing is typically less expensive than steel, but material choice depends on ground conditions and expected lifespan.

Beyond the initial drilling, there are often additional expenses that can add to the total cost. These can include:

- Hydrogeological surveys and site assessments to determine the best drilling location and water yield potential.

- Permitting and licensing fees, which vary significantly by local regulations.

- The cost of the pump system, including the pump itself, pressure tank, and all necessary plumbing and electrical connections.

- Well development and testing, which involves flushing the well and conducting yield tests to ensure proper water flow and quality.

- Water quality testing and potential treatment systems if the water does not meet potable standards.

- Ongoing maintenance and potential future repairs.

How Much to Order Drill Bits for Borehole Drilling?

Recommended Drill Bits for Borehole

The cost of drill bits for borehole drilling varies significantly depending on several factors, primarily the type of bit, its size (diameter), and the geological conditions it’s designed to penetrate. For softer formations like clay or sand, simpler and less expensive drag bits or auger bits might be sufficient, ranging from tens to a few hundred dollars.

However, for hard rock, specialized bits like DTH (Down-The-Hole) hammer bits, tricone bits (with tungsten carbide inserts), or PDC (Polycrystalline Diamond Compact) bits are necessary, and these can cost anywhere from a few hundred to several thousand dollars per bit, with larger or more specialized bits reaching into the thousands.

It’s crucial to understand that drill bits are consumable items and their lifespan depends on the rock formation and drilling practices. A single borehole project may require multiple bits, especially if the ground conditions are abrasive or inconsistent. When ordering, it’s not just about the upfront cost of a single bit, but also considering the potential need for replacements and having the right type of bit for different rock layers.

Here are some factors that influence the cost of drill bits:

Type of Drill Bits:

- Drag Bits: Generally the least expensive, used for soft formations like soil, clay, and sand. Prices can range from $50 – $200.

- Auger Bits: Also for softer ground, often used with auger drilling rigs. Costs can be in the range of $100 – $500+.

- Tricone Bits (Roller Cone Bits): Versatile for various rock types, with prices ranging from $300 – $2,000+ depending on size and insert material (milled steel teeth are cheaper than tungsten carbide inserts).

- DTH Hammer Bits: Designed for hard rock drilling with a percussive hammer. Prices typically start from $100 and can go up to $1,000 or more for larger, high-performance bits.

- PDC Bits (Polycrystalline Diamond Compact): Excellent for homogeneous soft to medium-hard formations and offer high penetration rates and longer life in suitable conditions. These are among the most expensive, ranging from $200 to several thousand dollars, with some specialized ones going into the tens of thousands.

- Core Bits: Used for taking core samples for geological analysis, typically more expensive due to their precision and diamond segments. Prices can vary widely based on size and diamond quality.

Diameter of the Bit: Larger diameter bits require more material and are generally more expensive.

Material and Construction: Bits made with higher-grade steel, tungsten carbide inserts, or diamond elements will cost more but offer better durability and performance in challenging conditions.

Brand and Manufacturer: Reputable brands often have higher prices but may offer superior quality and performance.

Quantity Ordered: Bulk orders may receive discounts.

Geological Conditions: The expected rock hardness and abrasiveness will dictate the type and durability of bits needed, impacting the total cost. You might need a range of bits for different layers.

Is Borehole Drilling Worth It?

For many property owners and businesses, borehole drilling can be a worthwhile investment with significant long-term benefits. The initial cost, while substantial, is often offset by the considerable savings on water bills over time. In areas with rising municipal water costs, unreliable supply, or water restrictions, a borehole provides an independent and consistent water source.

This independence offers peace of mind, knowing that essential water needs for domestic use, irrigation, or industrial processes will be met even during droughts or municipal supply interruptions. Furthermore, borehole water is often naturally filtered, free of chemicals like chlorine, and can even contribute to a healthier lifestyle.

Beyond the immediate financial and practical advantages, borehole drilling can also increase property value. A reliable, independent water supply is a highly attractive feature for potential buyers, especially in rural or semi-rural areas.

From an environmental perspective, boreholes can reduce the strain on public water resources and lower a property’s carbon footprint by minimizing the energy associated with municipal water treatment and transportation. While there are initial costs and ongoing maintenance to consider, the overall return on investment for a properly constructed and maintained borehole often makes it a valuable asset for years to come.

Conclusion

As we’ve explored, the cost of drilling a borehole is a multifaceted equation influenced by geology, depth, equipment, and ancillary services. While the initial investment might seem substantial, the long-term benefits of a reliable, independent water source often outweigh the upfront expenses.

A well-planned and professionally executed borehole can provide significant savings on water bills, enhance property value, and offer consistent access to water, even during periods of scarcity. It’s a valuable asset that offers both practical and financial returns over many years.

For drilling professionals and project managers looking to optimize costs without compromising quality, sourcing reliable equipment is key. Consider getting wholesale borehole drill bits from our trusted supplier, Sinodrills.