Heat treatment methods play a crucial role in improving the performance and longevity of drilling tools. Through controlled heating and cooling processes, the mechanical properties of drill bits and rods are significantly enhanced. This ensures excellent hardness, strength, and resistance to wear, helping them perform efficiently in harsh drilling environments.

For both mining and construction applications, heat treatment transforms standard steel into high-performance materials capable of enduring extreme stress and abrasion. Properly treated drill bits and rods maintain sharper edges, better torque resistance, and longer service life. Understanding these processes helps users select reliable tools for superior productivity and durability.

What is Heat Treatment?

Heat treatment is a controlled process of heating and cooling metals to alter their physical and mechanical properties without changing their shape. The goal is to enhance hardness, strength, ductility, and wear resistance, making the material more suitable for demanding applications like drilling, mining, and construction.

In the manufacturing of drill bits and rods, heat treatment plays a vital role in improving durability and performance. Processes such as annealing, quenching, and tempering modify the internal structure of the steel, balancing toughness and hardness. This ensures the tools can withstand extreme stress, friction, and impact during drilling operations.

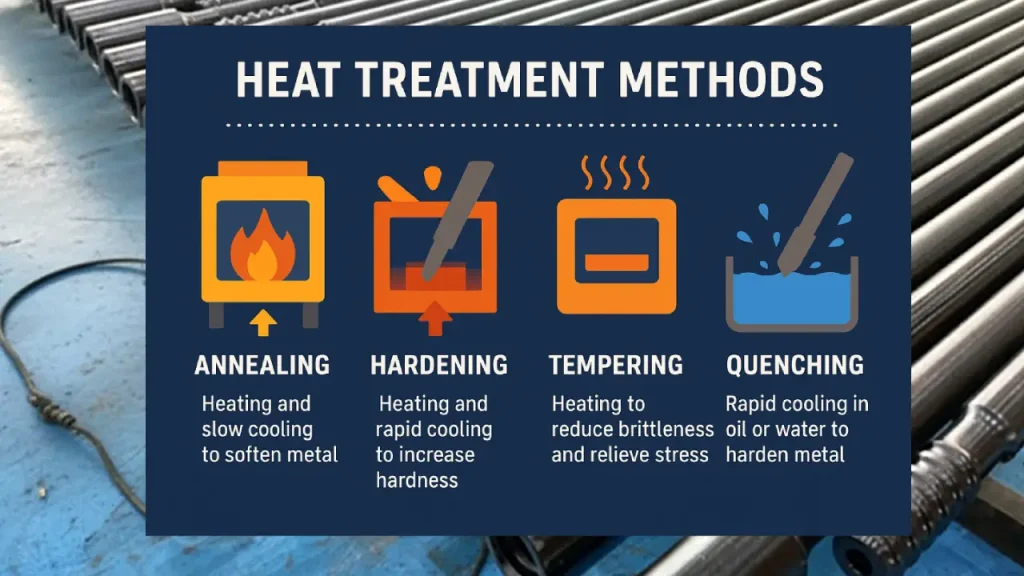

Heat Treatment Methods

Heat treatment is a critical process in enhancing the performance and lifespan of drilling tools. By carefully controlling temperature and cooling rates, metals can achieve optimal hardness, strength, and wear resistance. Different heat treatment methods cater to specific tool requirements, ensuring they withstand extreme drilling conditions while maintaining precision and durability, ultimately improving efficiency and reducing operational costs.

Annealing

Annealing is a heat treatment method used to soften metal, improve ductility, and relieve internal stresses. It involves heating the steel to a specific temperature, then slowly cooling it to refine its grain structure. This process enhances machinability and prevents cracking during later manufacturing stages.

In drill bit and rod production, annealing ensures uniform structure and reduces brittleness caused by prior processing. It prepares the material for further machining, threading, or shaping. The result is a more stable, flexible component that performs reliably under dynamic drilling conditions while maintaining dimensional accuracy and consistency.

Quenching

Quenching is a rapid cooling process that increases metal hardness and strength. After heating the material to a high temperature, it is quickly cooled using water, oil, or air. This sudden temperature change transforms the steel’s microstructure, significantly enhancing its wear resistance and load-bearing capacity.

For drill bits and rods, quenching provides the hardness needed to penetrate hard rock formations and resist abrasion. However, the process must be carefully controlled to avoid excessive brittleness. Proper quenching ensures a balanced combination of hardness and toughness, crucial for high-performance and long-lasting drilling tools.

Tempering

Tempering follows quenching to reduce brittleness while maintaining hardness. The metal is reheated to a lower temperature and held for a controlled period, allowing internal stresses to relax. This step fine-tunes the material’s mechanical balance, improving toughness and shock resistance.

In drilling applications, tempered bits and rods are more resilient under repeated impact and vibration. They maintain cutting efficiency and resist cracking or chipping in harsh environments. Tempering ensures that the tools not only perform effectively but also have a longer operational lifespan with consistent reliability.

Induction Hardening

Induction hardening uses electromagnetic induction to heat the metal’s surface rapidly, followed by quick cooling. This method hardens the outer layer while keeping the core tough and flexible. The process is ideal for components requiring high surface wear resistance and internal strength balance.

For drill rods and threads, induction hardening enhances resistance against surface wear and fatigue failure. The tough core absorbs impact energy, while the hardened exterior withstands abrasion during drilling. This combination results in superior durability, reduced maintenance, and improved performance in high-torque drilling operations.

Nitriding

Nitriding introduces nitrogen into the surface of the steel at high temperature to create a hard, wear-resistant layer. Unlike other methods, it does not require quenching, minimizing distortion and stress. The result is a surface with excellent hardness and corrosion resistance.

In manufacturing drill bits and rods, nitriding enhances lifespan and performance, especially in abrasive or corrosive conditions. It provides a smooth, durable surface that resists friction and extends tool life. Nitrided components are ideal for precision drilling where both toughness and wear resistance are essential.

How to Choose Heat Treatment Methods for Drilling Tools?

Choosing the right heat treatment method for drilling tools is essential for maximizing their performance and service life. Different metals and applications require specific processes to enhance hardness, toughness, and wear resistance. Careful selection ensures tools withstand harsh conditions while maintaining precision and efficiency.

- Consider the Material Type: Different metals respond uniquely to heat treatment. High-carbon steels, alloy steels, and tungsten carbide require tailored processes. Matching the method to the material ensures uniform hardness, prevents cracking, and enhances durability for optimal performance under high stress.

- Assess Tool Application: The intended drilling environment affects heat treatment choice. Tools used for soft rock need different properties than those for hard rock or abrasive surfaces. Considering application ensures the tool maintains sharpness, reduces wear, and improves penetration efficiency.

- Evaluate Required Hardness and Toughness: Balancing hardness and toughness is crucial. Excessive hardness can make tools brittle, while too much toughness reduces cutting efficiency. Heat treatment methods like quenching and tempering optimize this balance, enhancing resistance to impact, wear, and deformation.

- Review Production and Cost Constraints: Some heat treatment methods require more energy, time, or specialized equipment. Evaluating production capabilities and costs helps select a method that meets performance needs without exceeding budget or time limits, ensuring efficient manufacturing and consistent quality.

- Check Post-Treatment Stability: Tools must maintain properties under operational conditions. Proper heat treatment ensures dimensional stability, reduces residual stresses, and improves long-term performance. Selecting methods that minimize distortion and preserve structural integrity helps maintain tool accuracy and extends service life.

Conclusion

Heat treatment methods are the backbone of high-quality drilling tools, ensuring each bit and rod achieves optimal toughness and resilience. By controlling temperature and cooling cycles, manufacturers create materials that resist deformation, cracking, and fatigue. The result is a tool that performs reliably across a wide range of drilling conditions.

Advanced processes like quenching, tempering, and induction hardening not only enhance tool lifespan but also improve drilling efficiency and safety. Proper heat treatment reduces maintenance costs, minimizes downtime, and ensures consistent drilling output, making it essential for modern mining and construction operations.

At Sinodrills, we specialize in manufacturing and supplying premium-quality drill bits and drill rods with precise heat treatment for extended durability. Our products undergo strict quality control to ensure consistent performance in every drilling project. Contact Sinodrills today to get wholesale drill bits and drill rods that deliver lasting strength and unmatched value.