Unlock the complexities and discover the incredible potential of Horizontal Directional Drilling (HDD) with our comprehensive guide. This resource delves into the innovative techniques and crucial equipment that define modern trenchless technology, transforming how we install underground utilities and infrastructure.

Explore the strategic advantages of HDD, from minimizing environmental impact to overcoming challenging terrains. Whether you’re a seasoned professional or new to the field, our guide provides invaluable insights into planning, execution, and troubleshooting, ensuring successful and efficient drilling operations.

What Is Horizontal Directional Drilling?

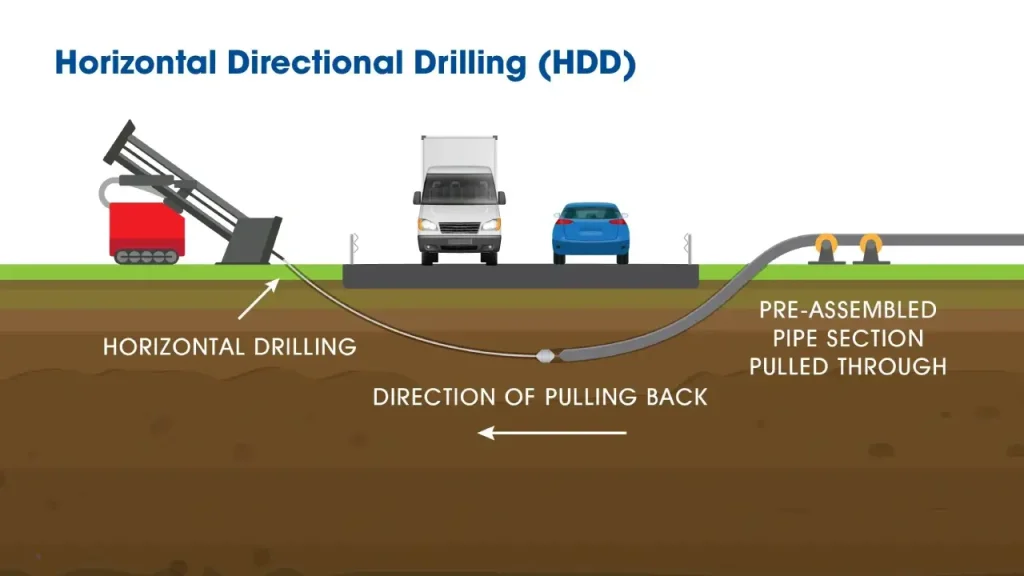

Horizontal Directional Drilling (HDD) is a trenchless method for installing underground pipelines, conduits, and cables without the need for extensive open-cut excavation. This technique involves drilling a precisely controlled pilot hole along a predetermined bore path, often navigating under obstacles like roads, rivers, or existing infrastructure.

After the pilot hole is complete, reaming tools are used to enlarge the bore to the desired diameter, and then the utility pipe is pulled through the enlarged hole. HDD minimizes surface disruption, reduces environmental impact, and offers a cost-effective solution for a wide range of underground utility installations.

Horizontal Directional Drilling Process

The Horizontal Directional Drilling (HDD) process is a sophisticated three-stage operation designed for efficient and minimally invasive underground utility installation. Each stage is crucial for ensuring the successful completion of the bore path and pipe placement.

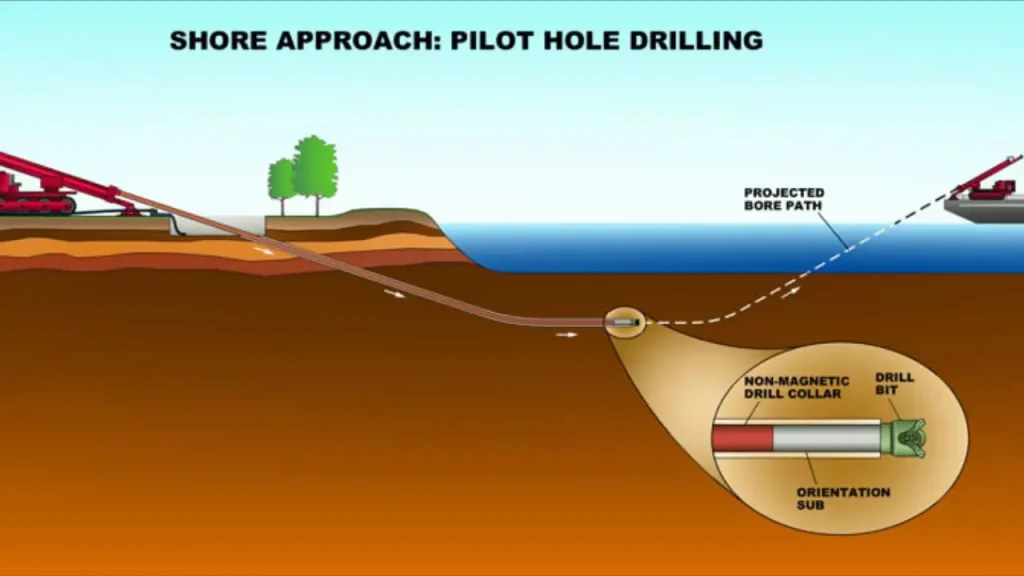

Pilot Hole

The first stage involves drilling a small-diameter pilot hole along the carefully planned underground path. A specialized drill rig initiates the bore from a surface entry point, guiding the drill string with a steerable drill head. This head is equipped with a transmitter that sends signals to a surface tracking system, allowing operators to precisely monitor the depth, location, and direction of the drill bit. Adjustments are made in real-time to ensure the pilot hole adheres to the designed trajectory, avoiding existing utilities and geological obstacles.

Drilling fluid, typically a mixture of water and bentonite clay, is continuously pumped through the drill pipe to the drill bit. This fluid serves multiple critical functions: it lubricates the drill bit, cools the downhole electronics, stabilizes the borehole walls by creating a filter cake, and most importantly, carries the excavated cuttings back to the surface entry pit.

The efficient removal of cuttings is vital to prevent the drill bit from becoming clogged and to maintain smooth drilling operations. Upon reaching the predetermined exit point, the pilot hole is complete, and the drill head is detached, preparing for the next stage of the HDD process.

Pre-Reaming

Following the completion of the pilot hole, the second stage, known as pre-reaming, commences. This involves progressively enlarging the pilot hole to a diameter sufficient to accommodate the final product pipe. A reamer, a larger cutting tool, is attached to the drill string at the exit point and pulled back towards the drill rig while rotating.

As the reamer rotates and moves through the pilot hole, it grinds and breaks up the soil and rock, expanding the borehole. During this process, drilling fluid continues to be circulated. The fluid helps to break down the soil, suspend the newly excavated cuttings, and transport them out of the borehole.

Multiple reaming passes may be necessary, especially for larger diameter pipes or in challenging ground conditions, with each pass using a progressively larger reamer. The goal of pre-reaming is to create a stable, clean, and appropriately sized bore that is ready for the final pipe installation, ensuring minimal friction and a smooth pullback.

Pipe Pullback

The final and often most critical stage is the pipe pullback. Once the borehole has been adequately enlarged through pre-reaming, the prefabricated product pipeline (e.g., water pipe, gas line, electrical conduit) is prepared at the exit side. A swivel is attached between the reamer and the leading end of the product pipe.

This swivel is crucial as it prevents the rotation of the drill string from being transferred to the pipe, protecting it from torsional stress and potential damage during the pullback. The drill rig then begins to pull the drill string back through the enlarged borehole, simultaneously drawing the product pipe into the ground.

As the pipe is pulled, drilling fluid is continuously pumped into the annular space between the pipe and the borehole wall. This fluid acts as a lubricant, reducing friction and facilitating the smooth passage of the pipe.

The pullback operation requires careful monitoring of tension and pressure to ensure the integrity of the pipe and the stability of the borehole. Once the entire length of the product pipe has been successfully pulled through the bore and reaches the entry point, the HDD installation is complete, and the connections to the existing utility network can be made.

Drilling Tools for Horizontal Directional Drilling

Drilling tools for Horizontal Directional Drilling (HDD) are specialized and robust, designed to withstand the rigorous demands of underground boring while ensuring precision and efficiency. These tools are crucial for every stage of the HDD process, from creating the pilot hole to successfully pulling the product pipe.

Drill Bits and Drill Heads

At the forefront of any HDD operation are the drill bits and drill heads, which are specifically designed to penetrate various ground conditions. For soft, unconsolidated soils like sand, clay, or gravel, fishtail bits or beaver tail bits are commonly used due to their aggressive cutting action and ability to displace material efficiently.

These bits often feature carbide inserts for enhanced durability. In harder formations, such as shale, sandstone, or fractured rock, roller cone bits (similar to those used in oil and gas drilling) or specialized PDC (Polycrystalline Diamond Compact) bits are employed. These bits use rotating cones or fixed diamond cutters to crush and shear the rock.

Drill heads are typically steerable, incorporating an angled face or jetting nozzles that allow operators to change direction by rotating the drill string to the desired orientation and pushing forward. This steerability is paramount for navigating complex bore paths and avoiding obstacles.

Drill Pipe

Recommended Drill Pipes

The drill pipe forms the backbone of the entire HDD system, transmitting rotation and thrust from the drill rig to the drill bit, and serving as the conduit for drilling fluid. HDD drill pipe is specially manufactured to withstand the significant torsional, tensile, and compressive stresses encountered during drilling and pullback. It is typically made from high-strength alloy steel, with precisely machined threaded connections (tool joints) that ensure secure and reliable coupling between individual sections.

The pipe comes in various lengths and diameters, chosen based on the length of the bore and the required torque and pullback forces. Internal flushing systems are often integrated to ensure the efficient flow of drilling fluid. The quality and integrity of the drill pipe are paramount, as any failure can lead to costly delays and complications in the drilling operation.

Reamers

Reamers are crucial tools used in the pre-reaming stage to progressively enlarge the pilot hole to the required diameter for the product pipe. Attached to the drill string, reamers are pulled back through the bore while rotating, grinding away the soil and rock. There is a wide variety of reamer designs, each suited for different ground conditions and bore sizes.

Barrel reamers or fly cutters are effective in cohesive soils, providing good hole cleaning and stability. For abrasive or rocky conditions, rock reamers with tungsten carbide inserts or hardened steel teeth are used to effectively break up harder formations.

Paddle reamers are suitable for sticky clays, as their open design helps prevent balling. Often, multiple reaming passes are conducted, using progressively larger reamers, to gradually increase the hole diameter. The selection of the appropriate reamer is critical for ensuring a stable and well-sized borehole that minimizes friction during the pipe pullback.

Swivels

Swivels are essential components during the pipe pullback stage, serving a vital role in protecting the product pipe from rotational forces. A swivel is connected between the leading end of the product pipe and the reamer/drill string assembly. Its primary function is to allow the reamer and drill string to rotate freely while the product pipe remains stationary.

Without a swivel, the rotational torque from the drill rig would be transferred directly to the product pipe, potentially causing it to twist, buckle, or even fracture. Swivels are designed to handle significant tensile loads during the pullback, ensuring a smooth and untwisted installation of the utility. They are available in various sizes and load capacities to match the requirements of different pipe diameters and pullback forces, guaranteeing the integrity of the installed pipeline.

Tracking and Locating Systems

Tracking and locating systems are the “eyes” of the HDD operator, providing real-time information about the exact position and depth of the drill head underground. These systems typically consist of a sonde (transmitter) located within the drill head and a receiver (locator) operated on the surface. The sonde emits electromagnetic signals that are picked up by the surface receiver, which then calculates and displays critical data such as depth, pitch (angle of inclination), and roll (orientation of the drill head).

Advanced systems can also map the bore path and record drilling parameters. This precise guidance is crucial for maintaining the planned bore path, avoiding existing underground utilities, and ensuring the drill head surfaces at the designated exit point. Accurate tracking minimizes the risk of costly strikes on existing infrastructure and ensures the environmental integrity of the project.

Drill Bits for Horizontal Directional Drilling (HDD)

Recommended HDD Drilling Tools

The effectiveness of Horizontal Directional Drilling (HDD) relies heavily on the selection of the correct drill bits, which are specifically designed to tackle the wide array of geological formations encountered underground. These specialized bits are engineered for optimal penetration, steering capability, and durability, ensuring efficient and successful pilot hole creation.

Different ground conditions necessitate distinct drill bit designs, ranging from those suited for soft, unconsolidated soils to those capable of cutting through hard rock. Each type features unique characteristics to maximize performance and minimize wear in its intended environment.

- Fishtail or Beaver Tail Bits: Ideal for soft, non-abrasive soils like sand, clay, and loam. Their flat, aggressive design efficiently displaces material and allows for good steering control.

- Claw Drill Bits: Excellent for mixed ground conditions, including compacted soils, gravel, and soft shales. They feature robust, often rotating, carbide cutters that aggressively break up material and provide good self-cleaning.

- Blade Bits (Paddle or Spade Bits): Versatile for a range of soft to medium soils, often with carbide inserts for extended life. Their broad surface area can assist with steering in less consolidated materials.

- Roller Cone Bits (Tricone Bits): Used for medium to hard rock formations, including sandstone, limestone, and shale. These bits feature rotating cones with steel teeth or tungsten carbide inserts (TCI) that crush and shear the rock.

- PDC (Polycrystalline Diamond Compact) Bits: Designed for hard, abrasive rock formations where traditional roller cone bits might wear too quickly. PDC cutters shear the rock efficiently, offering high rates of penetration and extended bit life in suitable conditions.

Conclusion

Horizontal Directional Drilling (HDD) stands as a cornerstone of modern infrastructure development, offering a minimally invasive and highly efficient method for installing underground utilities. Its ability to navigate obstacles, minimize surface disruption, and operate in diverse geological conditions makes it an indispensable technique for countless projects, from urban pipeline installations to sensitive environmental crossings.

This ultimate guide has highlighted the key principles, applications, and benefits that underscore HDD’s growing importance. From detailed planning and precise execution to advanced drilling tools and experienced personnel, each element contributes to the success of an HDD operation, ensuring projects are completed safely, cost-effectively, and with minimal impact on the surrounding environment.

For all your Horizontal Directional Drilling needs, including high-quality drilling tools, trust Sinodrills. Their comprehensive range of reliable and performance-driven equipment is designed to meet the demands of even the most challenging HDD projects, ensuring efficiency and success.