Self-drilling anchors have revolutionized ground support and fastening across numerous industries. These innovative anchors offer a streamlined installation process, eliminating the need for pre-drilling and separate grouting. This blog post will guide you through the essential steps and best practices for effectively using self-drilling anchors in your projects.

Understanding the proper techniques for self-drilling anchor installation is crucial for ensuring structural integrity and long-term stability. Whether you’re working on tunnels, slopes, or foundations, mastering their application can significantly enhance efficiency and safety. Let’s delve into the process to unlock the full potential of these versatile anchors.

What are Self Drilling Anchors?

Recommended Self Drilling Anchors

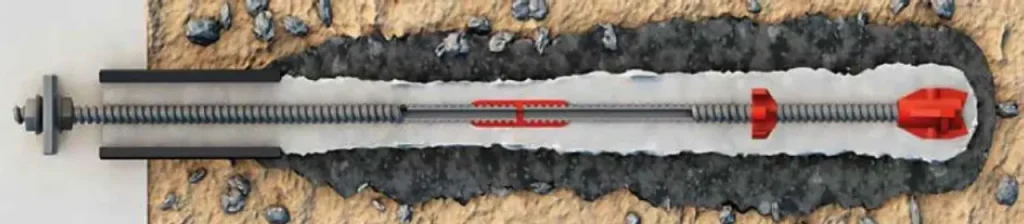

Self-drilling anchors are innovative fasteners that combine drilling, grouting, and anchoring into a single, efficient process. Unlike traditional anchor systems that require separate steps for pre-drilling and then installing the anchor and grout, self-drilling anchors feature a hollow steel bar with an external thread and a sacrificial drill bit at one end.

As the anchor is rotated and advanced into the ground by a drilling rig, it creates its own bore, and grout can be simultaneously injected through the hollow bar to stabilize the surrounding soil or rock. This integrated approach makes them particularly effective for unstable ground conditions, such as fractured rock, loose soil, or overburden, where conventional drilling methods might lead to borehole collapse.

How to Use Self Drilling Anchors?

Self-drilling anchors offer an efficient solution for ground support in challenging conditions. This guide will walk you through the process of their installation, ensuring a successful and secure application every time.

Step 1: Preparation and Equipment

Before beginning, ensure you have all necessary equipment, including the self-drilling anchor, a suitable drilling rig, and grout pump. Confirm the anchor type and size are appropriate for your specific ground conditions and project requirements. Safety gear is also paramount.

Inspect the anchor components for any damage or defects. Prepare the drilling site by clearing any obstructions and ensuring stable footing for the drilling rig. Proper setup minimizes complications during the drilling process and ensures efficient operation.

Step 2: Drilling the Borehole

Attach the self-drilling anchor to the drilling rig. Begin rotating and advancing the anchor into the ground, applying steady pressure. The sacrificial drill bit at the end of the anchor will create the borehole as it progresses through soil or rock.

Monitor the drilling progress closely, ensuring the anchor maintains a consistent path and angle. Adjust drilling parameters like rotation speed and feed pressure as needed, based on the encountered ground conditions, to ensure a smooth and continuous drilling operation.

Step 3: Grouting the Anchor

Once the anchor has reached the desired depth, or simultaneously with drilling, begin injecting grout through the hollow core of the anchor bar. This fills the annular space, bonding the anchor to the surrounding soil or rock.

Maintain consistent grout flow and pressure to ensure complete encapsulation of the anchor bar and adequate bond development. Proper grouting is critical for the anchor’s load-bearing capacity and long-term stability in the ground.

Step 4: Curing and Connection

Allow sufficient time for the injected grout to cure and gain strength. The curing time will vary depending on the grout mix used and ambient conditions. This step is crucial for the anchor to develop its full load-carrying capacity.

Once the grout has adequately cured, you can proceed with connecting the anchor to the structure. This typically involves attaching a bearing plate and nut to the exposed end of the self-drilling anchor, securing the connection firmly.

Step 5: Final Inspection and Testing

Perform a thorough final inspection of the installed anchor to ensure proper seating and secure connection. Check for any visible defects or issues that might compromise its performance. Clean up the work area of any excess grout.

If required by project specifications or engineering design, conduct load testing to verify the anchor’s capacity and overall performance. This confirms that the self-drilling anchor meets the required design loads and ensures the safety and stability of the supported structure.

Where to Use Self Drilling Anchors?

Self-drilling anchors are incredibly versatile, finding extensive application in geotechnical and civil engineering projects, especially where ground conditions are challenging or unstable. Their ability to simultaneously drill and grout makes them ideal for environments where boreholes might collapse using traditional methods.

- Slope Stabilization: These anchors are widely used to prevent landslides and erosion on unstable slopes, transferring forces through bearing plates to the anchor, which then resists movement via friction with the surrounding medium, preventing deformation.

- Tunneling and Mining: In underground construction, self-drilling anchors provide crucial roof and wall support, reinforcing rock masses and forming load-bearing arches to ensure safety during excavation, particularly in soft or fractured ground.

- Foundation Support: They serve as reliable solutions for underpinning existing structures or creating strong foundations in weak or variable soil conditions, transferring structural loads to more competent strata and mitigating settlement risks.

- Retaining Walls and Earth Retention: Self-drilling anchors are essential for reinforcing retaining walls, providing immediate anchoring and reinforcement to hold back soil and resist lateral pressures, ensuring long-term stability in both urban and rural settings.

- Temporary and Permanent Ground Support: Their rapid installation and adaptability make them suitable for both temporary shoring during excavation and permanent reinforcement of various structures, proving effective in diverse construction, mining, and civil engineering scenarios.

Self-Drilling Anchor Applications

Self-drilling anchors are revolutionary in geotechnical and civil engineering due to their ability to combine drilling, grouting, and anchoring into a single, efficient process. This makes them exceptionally useful in challenging ground conditions where traditional drilling might cause boreholes to collapse or where quick installation is critical.

Their versatility extends across various applications, providing robust and reliable ground support.

- Slope Stabilization: Crucial for preventing landslides and erosion on unstable slopes, self-drilling anchors effectively transfer loads and provide resistance against ground movement, ensuring long-term stability in vulnerable areas.

- Tunneling and Mining: In underground construction, they offer immediate and continuous support for tunnel roofs and walls, reinforcing rock masses and enhancing safety during excavation in varied geological conditions.

- Foundation Support and Underpinning: Used as micropiles or tie-backs, these anchors create strong foundations in weak soils or underpin existing structures, transferring loads to more stable strata and preventing settlement or uplift.

- Retaining Walls and Earth Retention: They are fundamental in anchoring retaining walls and providing temporary or permanent support for deep excavations, resisting lateral pressures and maintaining the integrity of the soil mass.

- Infrastructure Projects: From bridge construction to railway embankments, self-drilling anchors provide reliable anchoring solutions, adapting to diverse ground conditions and accelerating project timelines by streamlining the installation process.

Conclusion

In conclusion, mastering the use of self-drilling anchors is a valuable skill for anyone involved in modern construction and geotechnical work. By following the guidelines outlined in this blog, you can ensure efficient, secure, and reliable installations, saving both time and resources on your projects. Their adaptability to diverse ground conditions makes them an indispensable tool.

The advantages of self-drilling anchors – from their speed of installation to their robust performance – are undeniable. As you incorporate them into your operations, you’ll witness firsthand the enhanced safety and productivity they bring to challenging environments. Always prioritize proper technique and material selection for optimal results.

For all your project needs, consider sourcing high-quality self-drilling anchors from Sinodrills. We offer a comprehensive range of wholesale self-drilling anchors designed to meet the rigorous demands of various applications. Trust Sinodrills for reliable products that empower your success.