In self-drilling anchor system projects, the drilling efficiency and construction effectiveness of self-drilling anchor systems depend to some extent on whether the anchor bit matches the geological formation characteristics.

Currently, the industry's mainstream self-drilling anchor bits mainly consist of five types, each designed for specific formation characteristics to help engineering teams achieve precise construction.

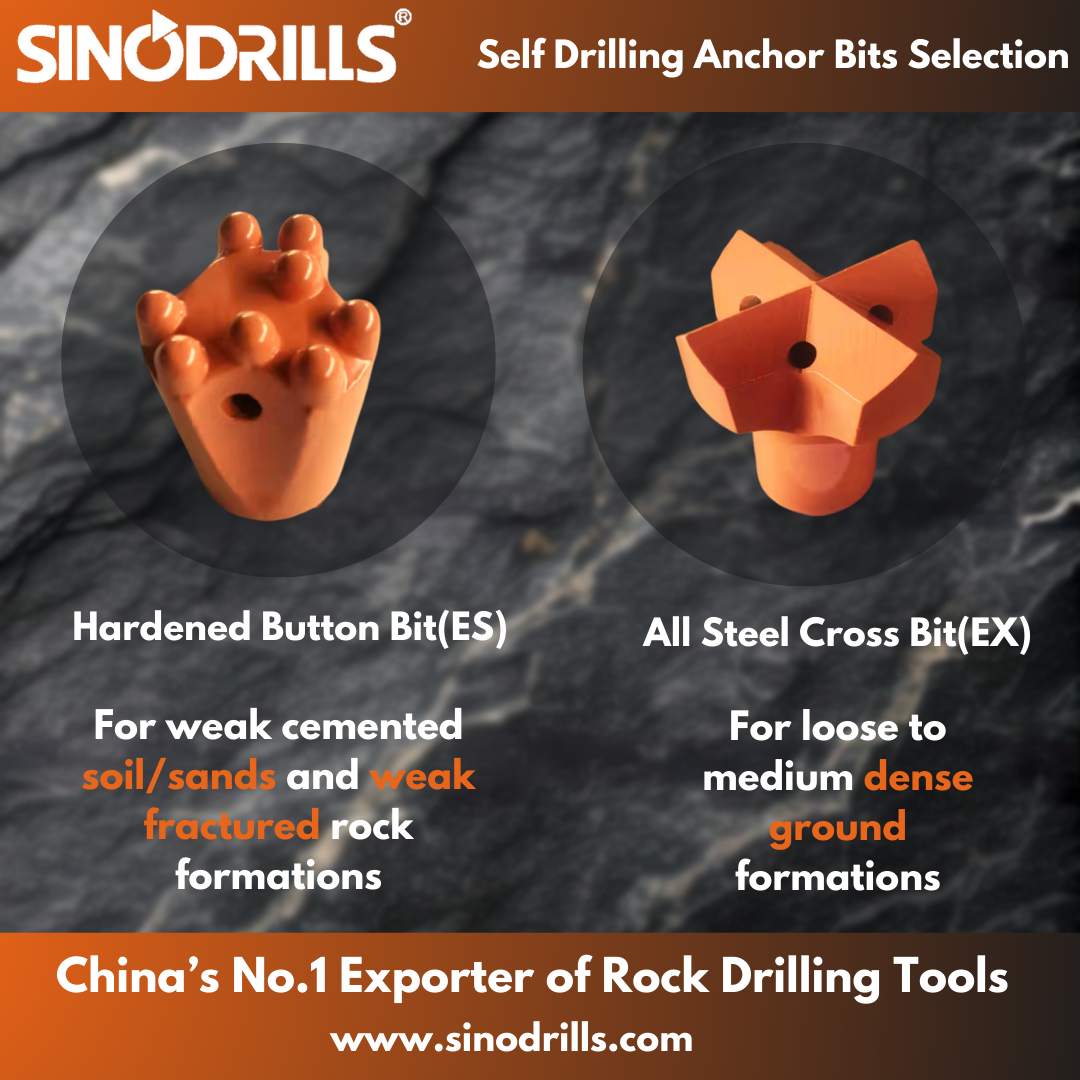

1. All Steel Cross Bit (EX)

Features: Cast or forged through machining, hardened via quenching.

Applicable Formations: Mudstone, gravel soil, backfill, weak mudstone, etc.

Advantages: Cost-effective all-steel structure; cross-blade design provides large contact area and high rotational cutting efficiency, enabling rapid fragmentation of soft rock.

2. TC Cross Bit (EXX)

Features: Cross-shaped blades welded with tungsten carbide blades to enhance rock-breaking capability and wear resistance.

Applicable Formations: Soft to medium-hard rock, heavily fractured formations, gravel layers with large boulders, unreinforced concrete, fissured rock layers.

Advantages: Welded with tungsten carbide blades to handle complex geological conditions effectively, reduce jamming, improve drilling efficiency, and offer better durability than normal all steel cross bits.

3. Hardened Button Bit (ES)

Features: Integrally cast all-steel buttons, with both the skirt and button made of high-strength steel for strong vibration resistance.

Applicable Formations: Weakly cemented sand, ordinary concrete, fragmented formations, soft sandstone, limestone, etc.

Advantages: Evenly distributed buttons minimize hole deviation; optimized buttons gap design prevents debris accumulation. Suitable for medium-depth anchoring, efficiently handling moderately hard and complex formations.

4. TC Button Bit (ESS)

Features: tungsten carbide buttons cold-pressed or welded in place, offering high wear resistance and penetration rate.

Applicable Formations: Medium to heavily fractured rock layers, weathered hard rock (e.g., mudstone, schist, boulder layers, etc.).

Advantages: High hardness of tungsten carbide buttons significantly enhances durability and extends service life.

5.Clay Bit (EW)

Features: Advanced blade design with reverse-flushing grouting holes for slag discharge and anti-clogging; cutting edges undergo heat treatment for improved wear resistance.

Applicable Formations: Clay, soft soil, sand, gravel, and other loose formations.

Advantages: High slag discharge efficiency and low cost, especially suitable for large-diameter drilling. An economical and efficient solution for loose soil layers.

With over 20 years of industry experience, Sinodrills has served global clients, providing precise solutions for countless anchoring projects. We already have the professional answers for your drilling challenges! Click to message or leave a comment to get your customized anchoring solution!