The IADC, or International Association of Drilling Contractors, plays a critical role in the oil and gas industry by setting standards and promoting safety. Understanding IADC classifications helps drilling professionals select the right equipment, optimize operations, and ensure compliance with global drilling practices.

IADC ratings provide insights into drill bit performance, formation suitability, and operational efficiency. By following these standards, companies can reduce downtime, improve drilling precision, and enhance overall safety. Awareness of IADC guidelines empowers operators to make informed decisions for both equipment and project planning.

What is IADC?

The IADC, or International Association of Drilling Contractors, is a global organization that sets standards for drilling operations.

It provides classifications for drill bits, promotes safety, and supports best practices in the oil and gas industry. IADC guidelines help optimize performance, reduce risks, and ensure consistent, efficient drilling worldwide.

Why IADC Matters?

The International Association of Drilling Contractors (IADC) plays a vital role in standardizing drilling operations, promoting safety, and improving efficiency.

Understanding IADC classifications helps operators select the right equipment, optimize performance, and maintain compliance with global drilling standards.

- Standardization of Equipment: IADC classifications provide a consistent framework for drill bit selection, ensuring that operators use suitable equipment for specific formations. This reduces errors, improves drilling accuracy, and enhances operational efficiency across different projects and environments.

- Enhanced Safety: By following IADC guidelines, drilling teams minimize risks associated with equipment failure and unsafe practices. These standards promote proper procedures, protect personnel, and reduce the likelihood of accidents on drilling sites, ensuring safer operations.

- Performance Optimization: IADC ratings help operators match drill bits to formation types and drilling conditions. This alignment improves penetration rates, reduces wear, and extends equipment lifespan, resulting in more productive and cost-effective drilling operations.

- Global Compliance: IADC standards are recognized worldwide, allowing companies to maintain consistency across international projects. Adhering to these standards ensures regulatory compliance, facilitates project approvals, and strengthens trust with clients and partners globally.

IADC Drill Bits

IADC drill bits are classified according to the International Association of Drilling Contractors system, providing standardized ratings for formation type, drilling efficiency, and durability. These bits help operators select the right tool for specific rock conditions, ensuring stable performance, reduced downtime, and optimized drilling results across projects.

- Formation Suitability: IADC drill bit classifications match bit types to specific rock formations. By selecting the appropriate bit, we ensure efficient penetration, reduced wear, and consistent drilling performance, minimizing operational delays and maximizing productivity in both soft and hard formations.

- Durability and Reliability: IADC-rated drill bits are engineered for long-lasting performance. We use high-quality materials and precise manufacturing techniques to maintain cutting efficiency, resist abrasion, and provide stable operation, reducing the need for frequent replacements and lowering overall operational costs.

- Operational Efficiency: These drill bits are designed to optimize penetration rates while minimizing vibration and downtime. We ensure that our IADC-classified bits enhance drilling speed, accuracy, and consistency, supporting smoother operations and more predictable project timelines.

- Safety and Compliance: Using IADC-classified bits ensures adherence to industry standards. We prioritize safe drilling practices, reducing the risk of equipment failure, protecting personnel, and maintaining compliance with global drilling regulations for reliable and responsible operations.

Types of Drill Bits with IADC

IADC classifications categorize drill bits based on their design, cutting structure, and formation suitability. Understanding these types helps operators select the right drill bits for efficient drilling, optimal performance, and reduced wear, ensuring reliable results across mining, oil, and construction projects.

- Tricone Drill Bits: Tricone drill bits feature three rotating cones with tungsten inserts, designed for a range of formations from soft to hard. We manufacture these drill bits for maximum penetration, stable rotation, and long service life, making them ideal for complex drilling environments.

- PDC Drill Bits: Polycrystalline diamond compact (PDC) drill bits provide continuous cutting with fixed diamond cutters. We customize these drill bits for durability, high penetration rates, and smooth operation, ensuring consistent performance in medium to hard formations with minimal maintenance.

- Drag Drill Bits: Drag drill bits have fixed blades for cutting soft formations efficiently. We design these drill bits to maximize surface contact, reduce vibrations, and improve drilling speed, providing cost-effective solutions for shallow wells and soft-rock projects.

- Core Drill Bits: Core drill bits are used for extracting cylindrical rock samples while drilling. We optimize these drill bits for precision, durability, and clean sample recovery, supporting geological studies, formation analysis, and resource evaluation in both exploration and production drilling.

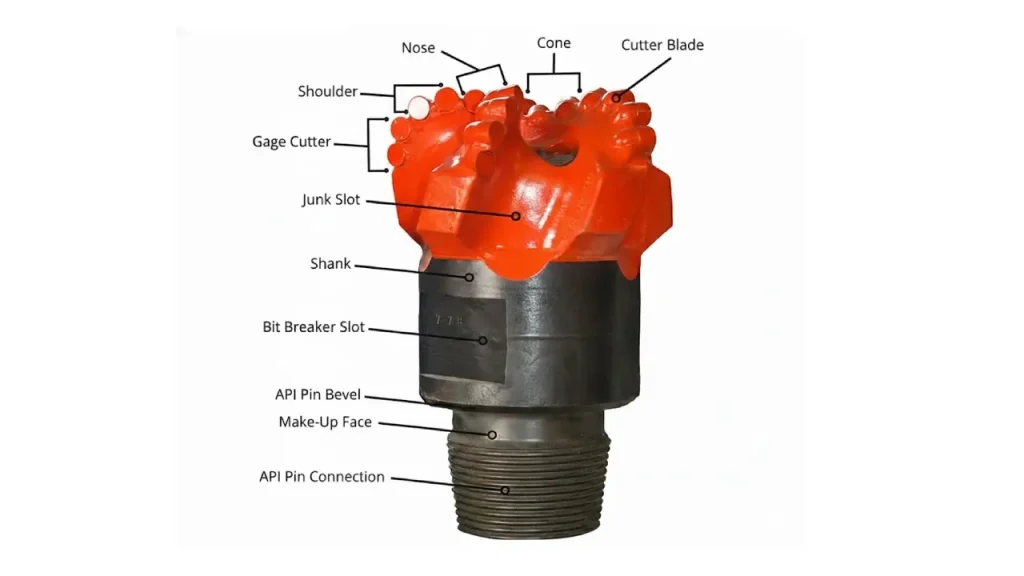

IADC Drill Bit Components

IADC drill bits consist of several critical components designed to ensure efficient drilling, durability, and stability. Each part contributes to the bit’s overall performance, helping operators penetrate formations effectively, maintain cutting efficiency, and reduce operational downtime in mining, oil, and construction projects.

- Cone: The rotating cone houses the cutters and transfers rotational force to the formation. We design cones to provide balanced rotation, reduce vibration, and ensure stable drilling, supporting consistent penetration rates and extending bit life in various rock conditions.

- Cutter Blade: Cutter blades are the primary cutting elements on the bit. We engineer blades with high-quality tungsten carbide or PDC materials to maximize cutting efficiency, resist wear, and maintain performance in both soft and hard formations.

- Gage Cutter: Gage cutters maintain the hole diameter and prevent undergauge drilling. We position these cutters strategically to ensure accurate borehole size, minimize reaming requirements, and protect the bit body from excessive wear.

- Junk Slot: Junk slots provide channels for cuttings and debris to exit the hole. We optimize their design to improve chip removal, reduce clogging, and maintain smooth drilling operations, enhancing overall efficiency.

- Shank: The shank connects the bit body to the drill string. We design shanks for strength and stability, allowing secure attachment, effective torque transfer, and reduced risk of bit loosening or failure during drilling.

- Bit Breaker Slot: Bit breaker slots help dissipate stress and reduce fatigue. We incorporate these slots to prevent cracks, extend bit life, and maintain consistent performance under high-pressure, high-torque drilling conditions.

- API Pin Connection: The API pin connection secures the bit to the drill string. We ensure precise threading for reliable attachment, leak prevention, and safe handling during drilling operations.

How to Choose IADC Drill Bits?

Selecting the right IADC drill bits is essential for efficient drilling, reduced wear, and reliable performance. Understanding formation type, drilling conditions, and IADC classifications helps operators choose bits that maximize penetration rates, minimize downtime, and deliver long-term durability in mining, oil, and construction projects.

- Consider Formation Type: Choose bits based on the hardness and abrasiveness of the rock formation. We recommend selecting IADC-classified bits that match formation characteristics to optimize cutting efficiency, reduce wear, and prevent unnecessary stress on the drill string during operations.

- Evaluate Drilling Conditions: Consider depth, rotational speed, and fluid type when selecting bits. We help match drill bits to operational parameters, ensuring stable performance, smooth rotation, and minimal vibration, which improves accuracy and overall project efficiency.

- Review Bit Material and Design: Drill bit materials and cutter configurations influence durability and penetration. We recommend high-quality PDC or tungsten carbide bits with optimized blade and cone designs to maximize life span and maintain consistent drilling performance.

- Check IADC Classification: IADC codes indicate suitable formations and operational parameters. We advise using these classifications as a guide to select the proper bit type, ensuring efficient penetration, reduced maintenance, and reliable results in specific drilling environments.

- Assess Performance History: Analyze past performance of similar bits in comparable formations. We review operational feedback and recommend bits proven to deliver consistent results, reducing downtime, improving productivity, and supporting safe, cost-effective drilling projects.

Conclusion

Understanding IADC classifications allows drilling teams to choose the right bits and tools for their projects, enhancing efficiency, safety, and cost-effectiveness. Following these standards reduces operational risks and ensures consistent performance in various formations. For reliable, IADC-compliant drill bits, trust our Sinodrills selection.

At Sinodrills, we offer a wide range of drill bits and drilling tools designed to meet IADC standards. Our products provide durability, high penetration rates, and long service life. Partnering with us ensures you have the right equipment for every drilling application, boosting productivity and project success.

Get wholesale drill bits and other drilling tools from Sinodrills today. We provide tailored solutions for mining, oil, and construction projects, delivering reliable performance and efficiency. With our expertise and quality products, your drilling operations can achieve optimal results with reduced downtime and enhanced safety.