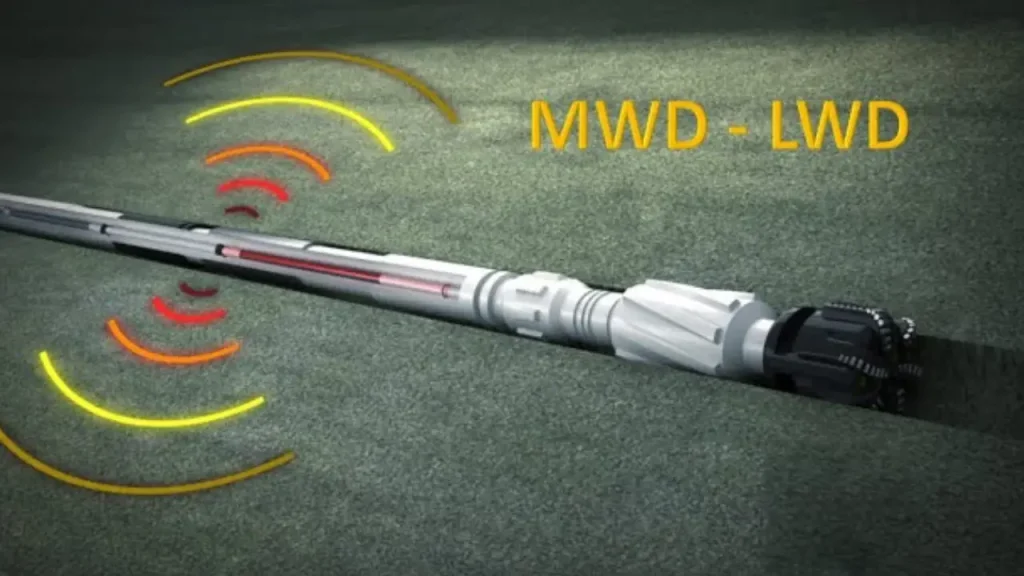

The modern oil and gas industry is defined by precision and efficiency, especially with the rise of complex directional and horizontal drilling. Downhole intelligence is crucial for success, and two technologies, Logging While Drilling (LWD) and Measurement While Drilling (MWD), have become indispensable. This blog will explore how these methods act as the essential “eyes and ears” of the drilling operation, drastically enhancing real-time decision-making.

While both LWD and MWD are deployed in the bottom-hole assembly (BHA), their primary functions differ significantly. MWD provides the directional guidance and drilling dynamics needed to steer the well, acting as the ‘ears’ for immediate adjustments. LWD, conversely, delivers detailed petrophysical data—the ‘eyes’—essential for evaluating the formation and accurately placing the well in the target reservoir.

What is LWD?

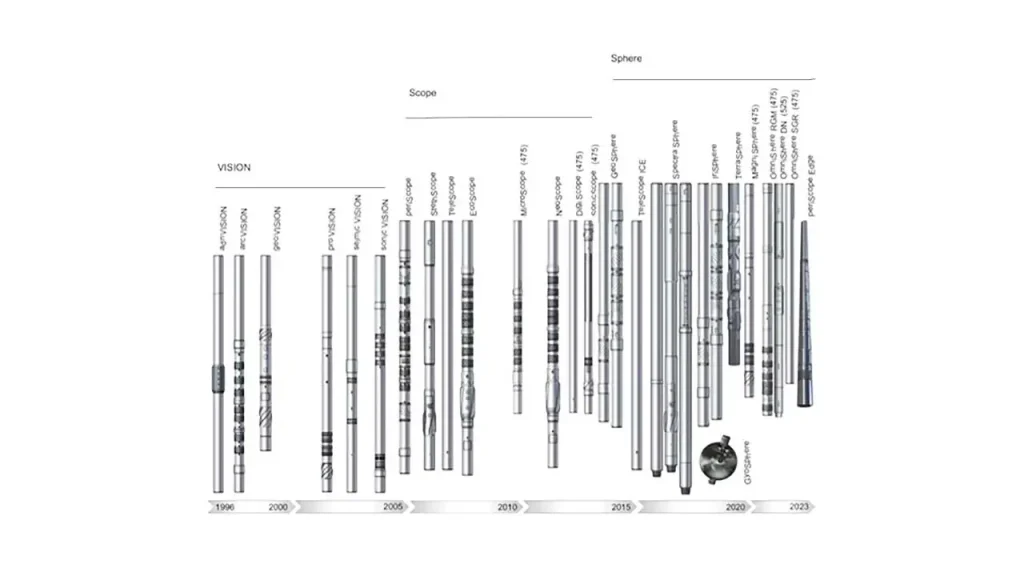

Logging While Drilling (LWD) is a sophisticated formation evaluation technology used in oilfield drilling. It involves integrating specialized tools into the drill string’s bottom-hole assembly (BHA) to acquire geological data in real time, serving as the essential “eyes” of the operation. This is critical for making informed, immediate adjustments.

- Real-Time Formation Data: LWD tools measure key geological properties like resistivity, gamma ray, and density immediately after the bit cuts the rock. This is vital for evaluating hydrocarbon saturation and lithology before drilling fluid invasion can compromise the data accuracy.

- Geosteering and Well Placement: This real-time data stream enables geosteering, allowing engineers to precisely steer the wellbore. It ensures the path remains within the most productive reservoir zones, maximizing contact with the oil or gas-bearing rock for optimum recovery.

- Replacing Wireline in Difficult Wells: LWD is often the only feasible method for obtaining formation logs in highly deviated or long horizontal wells, where conventional wireline logging tools struggle to reach the bottom. It streamlines the process by eliminating the need for a separate logging run.

What is MWD?

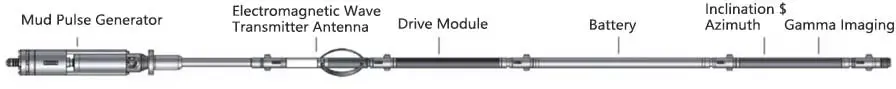

Measurement While Drilling (MWD) is the crucial technology that provides real-time directional and mechanical data to the surface during drilling operations. It is often referred to as the “ears” of the drilling process because its primary role is to monitor the wellbore’s path and the drilling dynamics. MWD ensures the well stays on its planned trajectory.

- Real-Time Trajectory Control: MWD uses sensors like accelerometers and magnetometers to continuously measure the wellbore’s inclination (angle from vertical) and azimuth (direction from north). This is essential for directional drillers to accurately steer the bottom-hole assembly (BHA) to the target zone.

- Downhole Drilling Dynamics: Beyond direction, MWD monitors critical drilling mechanics, including temperature, pressure, weight on bit (WOB), and downhole vibration. This real-time mechanical data is vital for optimizing drilling efficiency, preventing equipment damage, and ensuring the stability and safety of the wellbore.

- Data Transmission to Surface: The gathered downhole information is transmitted to the surface computer systems via telemetry, most commonly using coded pressure pulses (mud pulses) sent through the drilling fluid column. This enables immediate adjustments by the drilling crew, saving time and cost.

LWD vs MWD

LWD and MWD are the complementary intelligence systems of modern drilling. They are often run together in the bottom-hole assembly (BHA) to provide real-time information. While both collect data, their core functions and the parameters they measure are distinct.

Primary Function

MWD’s main function is to deliver directional data and drilling mechanics information in real time. It ensures that the wellbore stays on its designed trajectory, acting as the steering mechanism that guides the drill bit toward the target.

LWD’s main function is formation evaluation, collecting petrophysical measurements of the rock and fluid properties surrounding the borehole. It acts as the geologist’s eyes, determining if the drilled section is a hydrocarbon pay zone.

Measured Parameters

MWD primarily measures engineering parameters necessary for steering and operational control. These typically include the wellbore’s inclination (angle) and azimuth (direction), along with drilling dynamics like downhole temperature and pressure.

LWD measures geological parameters that characterize the formation. Key measurements include gamma ray (for lithology), resistivity (for hydrocarbon presence), and porosity (for fluid volume).

Data Focus

The data from MWD is primarily used for directional control and immediate safety. It helps the directional driller and drilling superintendent make split-second decisions to maintain the well path and ensure the mechanical integrity of the drilling process.

The data from LWD is used for geosteering and reservoir characterization. Geologists use it to precisely land the well in the “sweet spot” of the reservoir and to forecast the long-term production potential of the well.

Data Resolution

MWD data is typically transmitted at a low bandwidth, providing only a summary of critical directional surveys and drilling dynamics in real time. Full, high-resolution data is often saved to internal memory for later retrieval.

LWD tools generally store high-resolution petrophysical data in memory downhole. While some data is transmitted in real time, the comprehensive logs are only available when the tool is pulled to the surface, offering superior detail for analysis.

Tool Location

The MWD tool is often located higher up in the BHA to measure directional surveys and is crucial for linking the steering system to the surface control. Its non-magnetic collar minimizes magnetic interference.

LWD tools, which contain the sophisticated logging sensors, are placed closer to the drill bit. This proximity ensures the measurements are taken quickly, before drilling fluid has a chance to severely alter the formation characteristics.

Here is the table showing you the differences bwtween Measurement While Drilling (MWD) and Logging While Drilling (LWD):

| Aspect | Measurement While Drilling (MWD) | Logging While Drilling (LWD) |

| Primary Function | Directional drilling and wellbore trajectory control. | Formation evaluation and reservoir characterization. |

| Measured Parameters | Inclination, Azimuth, Downhole Pressure, Vibration. | Gamma Ray, Resistivity, Porosity, Density. |

| Data Focus | Steering the well and ensuring operational safety. | Finding and staying in the “sweet spot” (geosteering). |

| Real-Time Data | Low-bandwidth surveys and basic dynamics data. | Critical formation indicators (e.g., Gamma Ray) for real-time decisions. |

| Tool Location | Often higher up in the BHA, focused on trajectory. | Closest to the drill bit to sample the least-invaded rock. |

How to Choose LWD and MWD?

Choosing the right Measurement While Drilling (MWD) and Logging While Drilling (LWD) services is a critical planning step that directly impacts well efficiency, accuracy, and cost. This decision is based on the well’s specific geological and operational requirements, along with the complexity of the drilling path.

- Well Trajectory Complexity: If the well is directional or horizontal, MWD is mandatory to provide real-time guidance on inclination and azimuth for accurate steering. For simple vertical wells, a basic, periodic survey tool might suffice, but complex paths demand MWD’s continuous data.

- Reservoir Target Definition: LWD is crucial if the well is designed for geosteering, which means keeping the drill bit precisely within a thin, high-value reservoir layer. LWD’s formation measurements, like Gamma Ray and resistivity, make this precise targeting possible.

- Downhole Operating Conditions: The tools must be selected to withstand the environment; high-pressure/high-temperature (HP/HT) wells require specialized LWD and MWD tools. The tools’ maximum temperature and pressure ratings must exceed the expected downhole conditions.

- Required Data Suite: A basic MWD tool provides only directional and minimal drilling dynamics data. If you need full petrophysical data, such as density and porosity, you must include a full suite of LWD sensors in the bottom-hole assembly (BHA).

- Telemetry Requirements: The choice of mud pulse or electromagnetic (EM) telemetry depends on the drilling fluid type and formation resistivity. Mud pulse is more common but slow, while EM is faster but limited by highly conductive formations.

Conclusion

The partnership between LWD and MWD represents a significant leap in drilling technology. By integrating real-time directional control (MWD) with comprehensive formation evaluation (LWD), operators can optimize well placement, mitigate hazards, and significantly reduce operational time and cost. Their combined data stream ensures that the drill bit stays precisely within the most productive zones, maximizing the economic potential of every well.

Ultimately, maximizing drilling efficiency requires the best tools for the job. Just as LWD and MWD provide the intelligence, high-quality drilling equipment ensures execution. To complete your drilling package, you can get reliable, durable, and cost-effective wholesale drill bits and other essential drilling tools from our company, Sinodrills.

Invest in cutting-edge downhole intelligence and pair it with world-class hardware. Visit Sinodrills today to explore our full range of drilling tools and components designed for the harshest environments. Equip your team with the quality and reliability needed to fully leverage your LWD and MWD data, driving superior performance and return on investment.