When it comes to ground support and geotechnical engineering, Self-Drilling Anchor (SDA) systems offer a robust and efficient solution. These innovative anchors combine drilling, grouting, and anchoring into a single process, proving invaluable in challenging soil and rock conditions. However, not all SDAs are created equal.

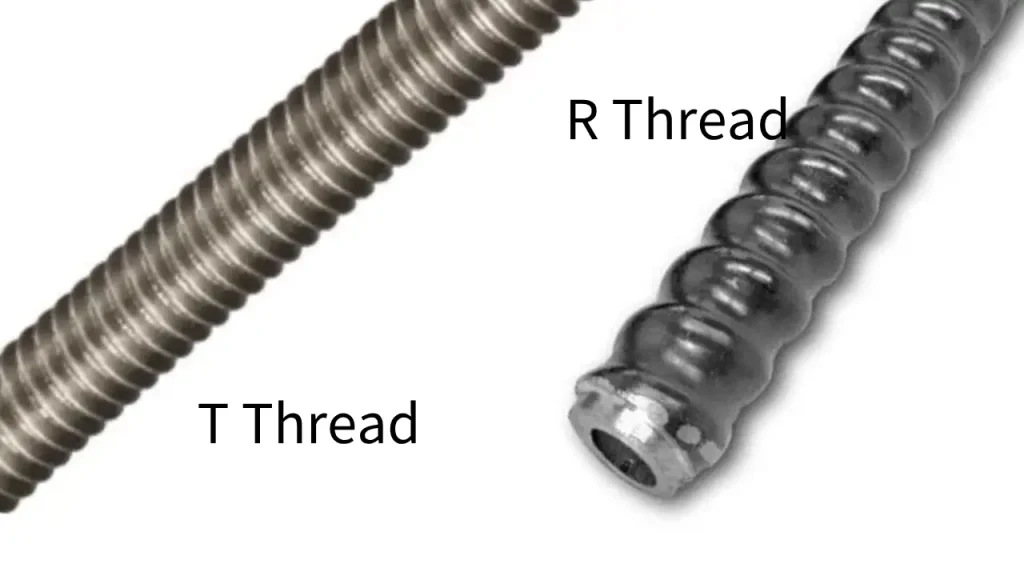

A critical distinction lies in their thread profiles: R-thread (Rope Thread) and T-thread (Trapezoidal Thread) systems.

Understanding the fundamental differences between these two types is crucial for selecting the optimal anchor system for specific project requirements, ensuring maximum efficiency and structural integrity.

What is a T-Thread Self Drilling Anchor?

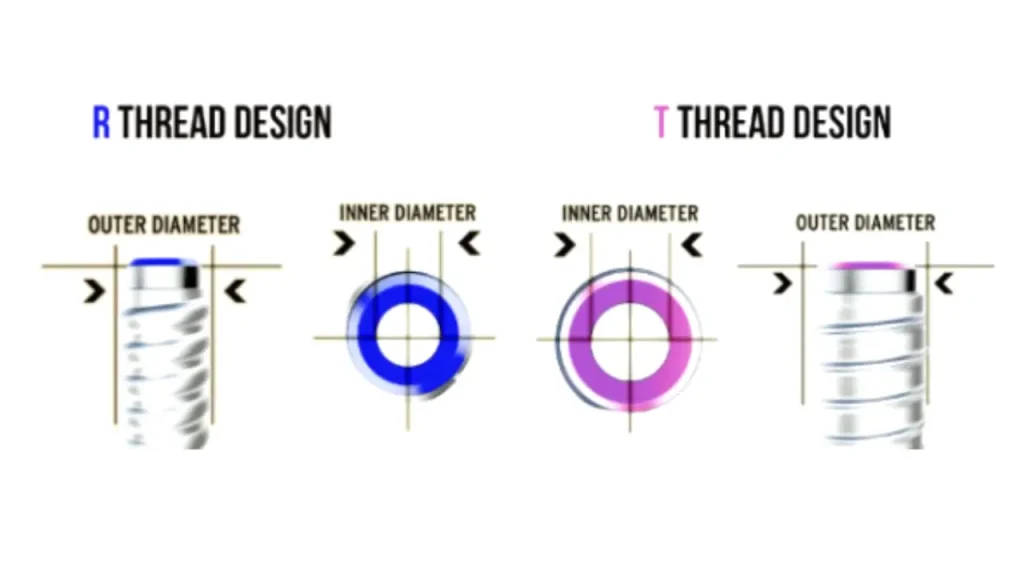

A T-thread Self-Drilling Anchor (SDA) is a specialized type of self-drilling anchor characterized by its robust, trapezoidal thread profile. This distinct design offers a significantly larger bonding surface with the injected grout compared to R-thread anchors, resulting in superior bond friction and ultimately, much higher load-bearing capacities.

Recommended T Thread Self-drilling Anchors

- Trapezoidal Thread Profile: The defining feature, providing a deep and strong thread that maximizes contact with grout.

- High Load Capacity: Designed for applications requiring substantial tensile and compressive strength, making them ideal for heavy structural support.

- Enhanced Bond Strength: The increased bonding area between the thread and grout leads to a more reliable and stronger connection with the ground.

- Durability in Challenging Conditions: Often preferred in highly fractured rock, loose soils, or other demanding geological formations where maximum support is critical.

- Common Sizes: Available in various sizes conforming to T International Standards (e.g., T30, T40, T52, T73, T103).

What is a R-Thread Self Drilling Anchor?

An R-thread Self-Drilling Anchor (SDA) is a type of hollow, threaded anchor bar used in self-drilling anchor systems. It is characterized by its continuous, wave-like or “rope” thread profile, which typically conforms to international standards like ISO 10208 and ISO 1720. This design facilitates efficient drilling and grouting in a single operation, making it a versatile choice for various ground support applications.

Recommended R Thread Self-drilling Anchors

Key characteristics and features of R-thread SDAs include:

- Continuous Thread Profile: The “rope” thread runs continuously along the entire length of the bar, allowing for easy cutting and connection with couplers.

- Self-Cleaning Properties: The thread design promotes efficient removal of drilled material during the drilling process, reducing the risk of borehole collapse.

- Standard Compliance: R-threads are manufactured to meet recognized international standards (e.g., ISO 10208), ensuring consistent quality and compatibility.

- Versatile Applications: Commonly used in smaller diameter anchor systems for general ground support, such as soil nailing, slope stabilization, and pre-supporting in tunneling.

- Ease of Installation: Combines drilling, grouting, and anchoring into one step, significantly reducing installation time and complexity, especially in unstable ground conditions where casing might otherwise be required.

R-Thread vs T-Thread Self Drilling Anchor

Self-drilling anchors are vital in modern geotechnical engineering, offering efficient ground support. Understanding the distinctions between R-thread and T-thread systems is crucial for optimal project selection. Their unique thread profiles dictate their performance across various applications.

Thread Profile

R-thread anchors feature a continuous, wave-like “rope” thread profile, typically adhering to ISO 10208 and ISO 1720 standards. This design, while robust, offers a more rounded and less aggressive profile, which contributes to its excellent self-cleaning capabilities during drilling, making it suitable for a wide range of ground conditions without significant clogging.

In contrast, T-thread anchors are characterized by a deeper, more pronounced trapezoidal thread profile, compliant with T International Standards. This distinct shape provides a larger surface area for engagement with the grout, leading to a significantly enhanced mechanical interlock and a stronger bond between the anchor bar and the surrounding ground.

Bond Strength and Load Capacity

The R-thread’s continuous profile, while effective for general ground support, offers a relatively smaller bonding surface area compared to the T-thread. This translates to good, but generally lower, ultimate bond strength and load capacity, making them suitable for applications requiring moderate support where the primary goal is often to provide stability and prevent localized failures.

T-thread anchors, with their aggressive trapezoidal thread, create a much larger contact area with the injected grout. This superior mechanical interlock results in significantly higher bond friction and, consequently, greater ultimate bond strength and load capacity.

This characteristic makes T-threads the preferred choice for demanding applications where high tensile or compressive loads are anticipated, such as in micropiles or heavy structural underpinning.

Self-Cleaning and Installation Efficiency

The rounded “rope” thread of R-thread anchors inherently facilitates better self-cleaning during the drilling process. Soil and rock cuttings are more easily flushed out through the hollow core, reducing the risk of clogging and ensuring smoother drilling progress, particularly in cohesive or challenging ground conditions. This results in efficient installation times for a wide range of projects.

While T-thread anchors are also designed for self-drilling, their deeper thread profile can, in some very fine or sticky ground conditions, be slightly more prone to clogging than R-threads, though appropriate drilling parameters and grout mixes often mitigate this. Their primary advantage in installation efficiency lies in their ability to achieve higher capacities in a single pass, often reducing the number of anchors required for a given load.

Geotechnical Applications

R-thread anchors are widely employed in general ground support applications where moderate loads and good drilling efficiency are key. This includes common uses like soil nailing for slope stabilization, pre-support (spiling/forepoling) in tunneling through relatively stable ground, and face stabilization in less aggressive rock or soil formations. Their versatility makes them a go-to for many everyday geotechnical challenges.

T-thread anchors excel in applications demanding higher performance and load transfer. They are frequently specified for micropiles, which act as small-diameter, high-capacity foundations for new structures or underpinning existing ones. Their superior bond strength also makes them ideal for heavy structural anchoring, deep foundations in challenging ground, and situations where maximizing load capacity per anchor is critical.

Cost-Effectiveness

Generally, R-thread anchors tend to be more cost-effective on a per-meter basis, especially in standard applications where their load capacity is sufficient. Their manufacturing process can be simpler, and their broader applicability across various ground conditions can lead to economies of scale. They represent a balanced choice for projects prioritizing efficiency and budget for moderate loads.

T-thread anchors, due to their more complex thread profile and higher material requirements for enhanced strength, typically come at a higher cost per meter. However, their superior load capacity can often lead to overall project savings by reducing the number of anchors required for a given load, or by enabling solutions in challenging conditions where R-threads might not be feasible, thereby offering long-term value in high-performance applications.

Here are some differences between R thread self drilling anchors and T thread self drilling anchors:

| Feature | R-Thread Self-Drilling Anchor | T-Thread Self-Drilling Anchor |

| Thread Profile | Continuous, wave-like (“rope” thread) | Deeper, more pronounced trapezoidal thread |

| Bond Strength | Good, moderate | Excellent, significantly higher |

| Load Capacity | Moderate | High to very high |

| Self-Cleaning | Excellent | Very good (can be slightly less than R-thread in fine soils) |

| Typical Applications | Soil nailing, slope stabilization, general pre-support, face stabilization | Micropiles, heavy structural anchoring, deep foundations, high-load applications |

| Cost-Effectiveness | Generally more cost-effective per meter | Higher cost per meter, but can offer overall savings due to fewer anchors needed |

How to Choose R-Thread and T-Thread Self Drilling Anchor

Choosing between R-thread and T-thread self-drilling anchors requires a careful assessment of several project-specific factors to ensure optimal performance, safety, and cost-effectiveness. The decision hinges primarily on the ground conditions encountered and the magnitude of the loads the anchors are required to withstand.

Here are key considerations for selecting the appropriate self-drilling anchor system:

Ground Conditions:

- R-thread: Ideal for a wide range of ground conditions, including fractured rock, glacial till, and granular soils. Their excellent self-cleaning properties make them particularly effective where there’s a risk of borehole clogging. They are often a versatile choice for general ground support.

- T-thread: Preferred for very challenging ground, such as highly fractured rock, weak rock masses, or where high bond strength is critical. Their aggressive thread provides superior engagement in more difficult formations, though in very fine or cohesive soils, attention to drilling parameters is important to prevent minor clogging.

Required Load Capacity:

- R-thread: Suitable for applications requiring moderate tensile and compressive load capacities. They are commonly used when the primary objective is to provide adequate stability and reinforcement without exceptionally high load demands, such as in standard soil nailing or light pre-support.

- T-thread: Mandated for applications where high to very high load capacities are essential. Their robust thread profile and larger bonding area with grout allow them to achieve significantly greater ultimate bond strength, making them ideal for micropiles, heavy structural underpinning, or deep foundation work where maximum load transfer is critical.

Project Budget and Efficiency:

- R-thread: Generally more cost-effective on a per-meter basis for standard applications. Their efficiency in installation across various common ground types can lead to overall time and cost savings for projects with moderate load requirements.

- T-thread: While often having a higher unit cost, their superior load capacity can potentially reduce the total number of anchors required for a project, leading to overall savings in material and installation time for high-load scenarios. They offer a high-performance solution that can be more economical in the long run for demanding applications.

Installation Equipment and Expertise:

Both R-thread and T-thread anchors utilize similar drilling equipment, but the specific drill bits and grouting pressures might be optimized for each type. Ensure your drilling rig and crew are familiar with the nuances of installing the chosen thread type, especially for T-threads where maximizing bond strength is paramount.

Design Life and Performance Requirements:

Consider the long-term performance and design life of the structure or excavation being supported. For critical infrastructure or applications requiring a very long service life under significant loads, the enhanced bond strength and reliability of T-thread anchors may be a more suitable choice, even with a higher initial investment.

Conclusion

Choosing between R-thread and T-thread self-drilling anchors ultimately depends on the specific demands of your project. R-threads offer versatility and excellent self-cleaning for general ground support, while T-threads deliver superior bond strength and higher load capacities for more demanding applications.

Careful consideration of ground conditions, required load-bearing capacity, and project budget will guide you to the most appropriate SDA system. Selecting the right anchor type ensures optimal performance, safety, and cost-effectiveness for your geotechnical solution.

For reliable and high-quality self-drilling anchors, including both R-thread and T-thread systems, consider our Sinodrills. We offer a comprehensive range of wholesale self-drilling anchors designed to meet diverse project requirements.