Every time a drill bit turns into rock or soil, its speed is measured in Revolutions Per Minute (RPM). This seemingly simple metric is actually one of the most critical factors a driller controls. RPM fundamentally determines how quickly rock is broken and how long your valuable drill bits will last on the job site.

Drilling successfully is a delicate balance. Running the RPM too high can instantly dull your cutting edges due to excessive heat, while running it too low can lead to inefficient rock breakage and wasted time. Understanding the optimal speed for your specific formation is the key to maximizing your Rate of Penetration (ROP).

What is RPM in Drilling?

RPM in drilling stands for Revolutions Per Minute, which is the measure of the rotational speed of the drill bit as it cuts into the subsurface material.

This speed is a critical operational parameter that must be carefully balanced with Weight on Bit (WOB) and the formation strength to achieve an optimal Rate of Penetration (ROP) while minimizing premature wear and damage to the drill bit cutting elements.

RPM Formula for Drilling

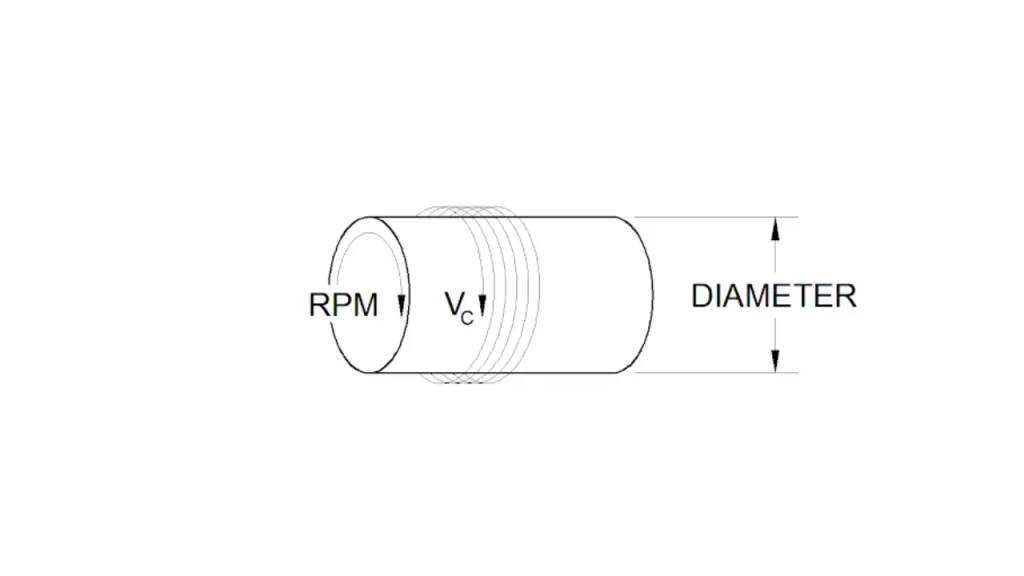

The RPM formula for drilling helps determine the optimal spindle speed (revolutions per minute) for a drill bit based on the cutting speed and diameter of the tool.

Basic RPM Formula

Where:

- RPM = Revolutions per minute (spindle speed)

- CS = Cutting Speed (surface speed) in feet per minute (fpm)

- D = Drill diameter in inches

Metric Formula

Where:

- CS = Cutting speed in meters per minute (m/min)

- D = Drill diameter in millimeters (mm)

What is RPM Used for?

RPM is a fundamental control parameter in drilling, used to manage the Rate of Penetration (ROP), ensure the longevity of the drill bit, and maintain hole quality. Adjusting Revolutions Per Minute allows the driller to fine-tune the cutting action based on the rock formation, tool size, and desired outcome, making it critical for operational efficiency and cost control.

⚙️ Primary Uses of RPM in Drilling

Controlling the Rate of Penetration (ROP)

RPM directly controls how frequently the drill bit’s cutting elements interact with the rock face. Generally, increasing RPM boosts ROP in softer formations by removing material faster, but in hard rock, increasing it too much can quickly lead to cutter damage and reduced efficiency.

Managing Heat and Bit Wear

Higher rotational speeds generate more friction and excessive heat at the cutting face. High temperatures can cause the cutters to dull or fail prematurely. Drillers must lower RPM for abrasive or hard materials to extend the bit’s service life and prevent thermal damage.

Optimizing for Rock Formation Hardness

The ideal RPM is inversely proportional to rock hardness. Soft formations (like shale) usually tolerate and benefit from higher RPM for speed. In contrast, hard, strong formations (like granite) require a lower RPM combined with higher Weight on Bit (WOB) to crush the rock effectively.

Preventing Drilling Dysfunctions

An incorrect RPM can lead to damaging drilling dynamics like bit whirl (unstable side-to-side movement) or excessive vibration. By carefully selecting the RPM, often in coordination with WOB, the driller ensures the bottom hole assembly (BHA) remains stable, resulting in a straighter, cleaner bore.

Drilling Speed Factors

Drilling speed for rock drill bits depends on multiple operational and geological factors that influence penetration efficiency and tool lifespan. Understanding these elements helps optimize productivity, reduce bit wear, and achieve consistent performance across different rock formations and drilling environments.

- Rock Hardness: Harder rocks reduce drilling speed because they resist bit penetration and cause higher friction. Softer formations allow faster drilling with less wear. Selecting the proper bit design and grade for the rock hardness ensures balanced performance and longer bit life.

- Bit Type and Design: The geometry and material of a rock drill bit affect cutting efficiency and rotation rate. Tungsten carbide and diamond bits provide superior performance on hard rocks. Proper selection helps maintain faster penetration and reduces energy loss during deep drilling operations.

- Rotational Speed (RPM): Proper RPM improves drilling precision and chip removal. Too high speed overheats the bit, while too low speed causes inefficient penetration. Adjusting RPM according to bit size and rock hardness helps maintain smooth drilling and minimizes tool damage during operation.

- Feed Pressure: The applied thrust or feed pressure controls how effectively the bit cuts into the rock. Excessive pressure causes premature wear or bit breakage, while low pressure reduces penetration rate. Maintaining optimal pressure improves cutting action and overall drilling efficiency.

- Flushing and Cooling: Effective flushing removes rock cuttings and dissipates heat from the bit face. Poor flushing clogs holes and increases friction. Using proper air or water flushing ensures smoother operation, enhances cooling, and prolongs the bit’s working life under demanding drilling conditions.

Conclusion

Revolutions Per Minute (RPM) is the pulse of any drilling operation, dictating efficiency, thermal management, and the crucial relationship with Weight on Bit (WOB). Mastering the correct rotational speed for varying rock types—from soft shale to hard granite—is essential for achieving peak performance and extending the service life of your tools.

The best RPM strategy is only effective when paired with superior hardware designed to withstand the stress. Durable, high-quality drill bits and tools are engineered to hold their cutting edge even under optimized, high-stress conditions. To ensure your drilling parameters translate to measurable success, you need reliable components.

When you are ready to implement a professional drilling strategy with confidence, the quality of your equipment is non-negotiable. Get reliable, high-performance wholesale drilling tools directly from Sinodrills. We supply the specialized bits, rods, and anchors you need to drill faster, smarter, and with greater cost efficiency.