Custom Tapered Drill Bit Manufacturer in China

We are a leading custom tapered drill bit manufacturer in China, specializing in high-performance rock drilling tools for mining, quarrying, and construction. Our expertise in tungsten carbide and advanced hot-pressing technology ensures exceptional penetration rates and extended durability, even in the toughest, most abrasive rock formations. We offer tailor-made solutions to perfectly meet your unique project specifications.

Sinodrills - Your Trusted Tapered Drill Bit Manufacturer from China

Tapered Drill Bit Features

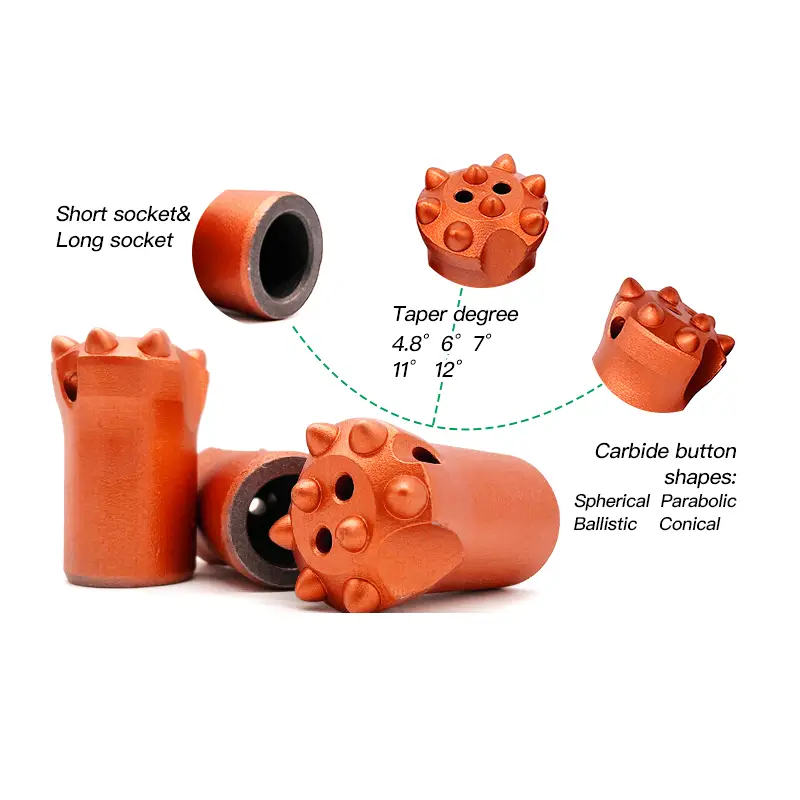

Tapered Interface Design The conical shape of the drill bit’s base ensures a firm and stable connection with the tapered drill rod, significantly reducing looseness during high-impact drilling operations. This interface ensures optimal energy transfer from the jackhammer to the rock face, which is vital for maintaining a high drilling speed and overall productivity.

Tungsten Carbide Buttons Buttons are the cutting elements, made from incredibly resilient tungsten carbide, and are hot-mounted into the bit’s body. These buttons come in various shapes like spherical, ballistic, or conical to match the abrasive nature and hardness of different rock formations.

Variety of Taper Angles Common taper angles include 4.8∘, 6∘, 7∘, 11∘, and 12∘ to suit different rock hardness and drilling requirements. The selection of the precise taper angle is a critical factor for achieving maximum drilling efficiency, hole accuracy, and bit lifespan in varying geological conditions.

Hard Rock Applications These bits are primarily designed for drilling through medium-hard to very hard and abrasive rock formations in demanding work environments. They are indispensable tools across industries such as quarrying, deep mining, tunnel construction, and various other civil engineering or blasting projects.

Tapered Drill Bit Benefits

Precision and Stability: The tapered shank design ensures a secure, firm lock in the machine spindle, dramatically minimizing wobble and vibration for highly accurate and clean hole-making.

Enhanced Durability: Crafted typically from solid carbide or premium high-speed steel, their robust construction and superior hardness allow them to withstand high temperatures and wear, extending the tool’s lifespan considerably.

Optimal Chip Management: The specific flute geometry is optimized to efficiently evacuate chips from the increasingly narrow tapered hole, preventing clogging and reducing heat buildup during deep-hole drilling operations.

Versatile Application: These bits are highly effective for drilling in a wide range of materials, including hard metals, wood, and plastic, making them essential for diverse industrial and professional woodworking projects.

Continuous Taper Angle: The continuous tapered cutting edge is precisely ground to produce a consistently accurate cone-shaped hole from entry to full depth, critical for creating exact fits for components.

How Many Drill Bit Buttons

- Rock Hardness Levels: Harder rocks need more buttons to share the load. This prevents premature breakage and helps we maintain steady drilling progress.

- Bit Diameter Dimensions: Larger bits require extra buttons for full surface coverage. We ensure no rock remains uncut by scaling button count with size.

- Targeted Penetration Rates: We optimize button density to balance impact pressure. This ensures you get the fastest cutting speed without straining your drilling equipment.

- Cuttings Removal Space: Buttons must leave room for flushing out debris. We space them to prevent regrinding, which keeps your drill bits running cooler.

- Gauge Wear Protection: Abrasive ground requires more buttons on the outer edge. We add these to protect the bit diameter during deep hole projects.

Various Tapered Drill Bit

tapered rock hammer drill bits

We offer a robust selection of tapered rock hammer drill bits designed for hand-held pneumatic and hydraulic rock drills. Our range includes durable button bits, cross bits, and chisel bits with common taper angles like 7∘, 11∘, and 12∘. These high-performance, carbide-tipped tools ensure superior penetration and longevity in various hard rock conditions for quarrying, mining, and construction.

mining tungsten carbides taper button rock drill bit

We offer a comprehensive selection of mining tungsten carbide taper button rock drill bits for top-hammer drilling. Our bits feature premium carbide inserts and robust steel bodies with taper degrees including 7∘, 11∘, and 12∘. We provide various button shapes (e.g., spherical, ballistic) and head diameters to ensure maximum drilling speed and longevity in different rock formations.

tapered drill bits for rock drilling

We offer a full line of tapered drill bits for rock drilling, primarily focusing on robust tapered button bits and cross bits. These are available in common taper degrees (4∘,6∘,7∘,11∘,12∘), various diameters (26mm to 60mm), and are engineered with premium tungsten carbide for superior hardness and longevity in hard rock formations.

12 degree tapered drill bits

We offer high-performance 12 degree tapered drill bits, featuring robust carbide button inserts for superior longevity and fast penetration rates in hard rock formations. This steep taper angle is engineered for easy bit uncoupling, making them ideal for high-impact drilling in mining, quarrying, and tunneling operations. Available in various diameters.

long skirt tapered drill bits

Our specialized long skirt tapered drill bits are engineered for maximum durability and performance in demanding rock drilling applications, such as mining and tunneling. The extended skirt length provides superior guidance and increased stability during deep hole drilling. This feature ensures optimal power transfer, reduces wear on the bit body, and extends the lifespan of the tool for continuous, cost-effective operation.

7 degree tapered drill bits

Our premium 7-degree tapered drill bits are specifically engineered for the mining, quarrying, and small-hole drilling industries. This precise angle ensures superior energy transfer and efficient rock penetration, maximizing your jackhammer’s performance. The robust tungsten carbide inserts deliver extended service life, which consistently leads to lower overall drilling costs and higher on-site productivity.

small hole tapered rock drill bits

We offer small hole tapered rock drill bits designed for precision drilling in hard and medium-hard rock. These bits provide stable performance, accurate hole alignment, and efficient energy transfer. Ideal for quarrying, mining, and construction, our tapered drill bits deliver reliable penetration, reduced wear, and consistent results in demanding drilling environments.

tapered rock drill bits with 7 teeth

Tapered rock drill bits with 7 teeth are designed for efficient penetration and stable drilling in hard rock conditions. We offer durable bits with precise taper angles and balanced tooth layouts, delivering strong impact transfer, reduced vibration, and reliable performance for mining, quarrying, and construction drilling applications.

custom length tapered button drill bits

We offer custom length tapered button drill bits designed to meet specific rock drilling requirements. Tailored lengths improve stability, energy transfer, and drilling accuracy in hard rock conditions. Manufactured with durable materials and precise tapering, our drill bits ensure reliable performance, extended service life, and compatibility with various drilling rigs and applications.

long skirt tapered drill bits

Long skirt tapered drill bits are designed for hard rock drilling where stability and guidance are critical. The extended skirt improves alignment, reduces vibration, and enhances energy transfer during drilling. We offer durable long skirt tapered drill bits with precise taper angles, ensuring reliable penetration, longer service life, and consistent performance in mining and quarry applications.

Customize Your Desired Tapered Drill Bit

Taper Angle and Diameter Specification

We precisely control the taper angle (e.g., 7∘, 11∘, 12∘) to guarantee a flawless, secure connection with your existing drill rods. Simultaneously, we customize the bit diameter to the exact hole size you require, balancing rock hardness with required flushing capabilities for optimal performance and chip evacuation.

Carbide Button Configuration

We offer a range of tungsten carbide button shapes, including spherical for long life in abrasive rock, parabolic for faster penetration in softer ground, or ballistic for high-speed drilling. We adjust the layout and number of buttons on the bit face to optimize the energy transfer for maximum rock-breaking power.

Skirt Length and Flotation Design

We can modify the skirt length to ensure correct mating with your rock drill’s chuck, preventing premature wear and failure. Furthermore, we customize the flushing hole design and location to manage air or water flow, ensuring quick and effective debris removal from the borehole.

Alloy Steel Body Material

We select specialized high-grade alloy steel for the bit body, offering superior tensile strength and fatigue resistance tailored to the percussive forces of your drilling machine. We also apply proprietary surface treatments, such as hot-zinc coating, to enhance corrosion resistance and prolong the overall service life of the drill bit.

what is tapered drill bit?

A rock tapered drill bit is a crucial tool used in mining, quarrying, and construction for drilling holes in hard rock formations, primarily for blasting or bolting operations.

It is characterized by its tapered skirt—a conical end designed to fit and lock securely into the corresponding tapered connection on a drill rod (often called a tapered drill rod or steel).

This connection relies on a friction-fit mechanism, where the impact and rotation of the rock drill drive the bit onto the rod, forming a strong, non-threaded link that prevents slippage and efficiently transfers the high impact energy needed to fracture the rock.

what is tapered drill bit used for?

Tapered drill bits serve several vital functions, primarily focused on providing a precise, clean, and secure fit for fasteners or specialized drilling in various construction materials and manufacturing.

The unique shape, which is either conical or stepped, determines its specific application, ranging from delicate woodworking to heavy-duty rock excavation.

Creating Flush Screw Seats (Countersinking) This is the most common use in woodworking. The bit drills a tapered pilot hole and simultaneously creates a conical recess for the screw head. This allows the fastener to sit perfectly flush with the material surface, improving the aesthetic finish and preventing snags.

Pilot Holes for Wood Screws Tapered bits drill a hole that matches the profile of a wood screw, being wider for the shank and narrower for the threaded portion. This minimizes the risk of wood splitting, especially in hardwoods, and ensures the screw achieves its maximum holding power and a secure fit.

Rock Drilling and Blasting In mining, quarrying, and construction, specialized tapered button or chisel bits are used with pneumatic rock drills. The tapered body locks into the drill rod for excellent energy transfer to fracture hard rock for excavation and creating blast holes efficiently in challenging geological formations.

Enlarging and Deburring Holes (Step Drills) A type of tapered bit, known as a step drill, features multiple diameters on a single body. This allows a single tool to gradually enlarge holes in thin materials like sheet metal or plastic without deforming them, also automatically deburring the edges for a clean finish.

where to use tapered drill bits?

Tapered drill bits are utilized across several industries and crafts where precise hole geometry, secure fastening, or specialized drilling is required. Their use extends from creating aesthetically pleasing joints in fine carpentry to heavy-duty industrial applications like rock excavation. The key is matching the bit’s tapered design to the specific job requirement.

Fine Woodworking and Cabinetry In these applications, tapered bits (often with a countersink) are essential for preparing holes that perfectly match the shape of wood screws. This ensures the screw head is flush with the wood surface, preventing splitting in delicate materials, and creating professional, secure joints in furniture or trim.

Rock Drilling and Mining Operations The heavy-duty, carbide-tipped tapered bits are widely used with handheld and lightweight mechanical rock drills. They are crucial in tunnel construction, quarrying, and for drilling blast holes, utilizing the tapered connection to efficiently transfer the powerful impact energy into hard rock.

Thin Sheet Metal and Plastic Fabrication Step drills, which are a type of tapered bit with multiple graduated diameters, are ideal for these materials. They allow for making several hole sizes with one tool and are uniquely effective at drilling clean holes in thin stock without deforming or cracking the material.

Heavy-Duty Machine Tools (Taper Shank Drills) Tapered shanks (like Morse Taper) are used to mount large drill bits directly into the spindles of drill presses or lathes. This creates a highly secure, self-locking connection based on friction, essential for safely transmitting the very high torque required for drilling large holes in metal.

why choose our tapered drill bits?

You should choose our tapered drill bits because their specialized geometry is engineered to deliver superior results, particularly in applications requiring a precise fit for fasteners and enhanced drilling performance in tough materials. They are designed for both professional precision and industrial durability.

Superior Screw Holding Power The tapered pilot hole perfectly matches the body and threads of traditional wood screws, ensuring maximum thread contact with the wood. This fit dramatically reduces the chance of wood splitting and creates a joint with far greater holding strength and durability than straight-drilled holes.

Eliminates Bit “Wander” The inherent stability of the tapered design, often combined with a sharp point, minimizes the bit’s tendency to drift or “walk” when starting a hole. This provides pinpoint accuracy right from the start, ensuring that your hole alignment is always exactly where you need it to be.

Reduced Friction and Heat Many tapered bits feature a back taper—a gradual decrease in diameter from the tip toward the shank. This feature significantly reduces surface contact friction, which in turn mitigates heat buildup, leading to less wear on the tool and a longer working life.

Optimized Chip Evacuation The design, particularly with tapered countersink bits, creates a wider channel and deeper flutes near the top of the hole. This improved geometry allows wood chips and debris to be cleared more efficiently during drilling, preventing clogging and ensuring a smoother, faster cutting action.

Send Your Inquiry Now

All-in-one Tapered Drill Bit Solutions for Your Project

Optimize your rock drilling with our precision-engineered Tapered Drill Bit Solutions. We custom-design bits with the ideal taper angle, carbide button shapes (spherical, ballistic), and body materials to perfectly match your rock type and drilling equipment. This tailored approach ensures superior penetration, minimal wear, and reduced overall cost per meter for your mining, quarrying, or construction project.