Rock bolts are an essential component of modern civil and mining engineering. They are used to stabilize rock masses and prevent ground collapses in tunnels, mines, and excavations. This guide will provide a comprehensive overview, explaining what rock bolts are, how they function, and their critical role in ensuring worker safety and project success.

From the basic principles of ground reinforcement to the various types of rock bolts available today, we’ll cover everything you need to know. Whether you’re a student, an industry professional, or simply curious about geotechnical engineering, this guide is your ultimate resource for understanding rock bolts.

What are Rock Bolts?

Rock bolts are long anchor bolts used in geotechnical engineering and underground construction to stabilize and reinforce rock masses. They are inserted into pre-drilled holes in the rock, and their primary function is to transfer the load from the unstable outer layers to the more stable, confined interior of the rock mass.

By “knitting” the rock layers together, they prevent movement and unraveling, thereby enhancing the overall stability of the structure. This makes them a fundamental component in ensuring the safety of tunnels, mines, and slopes.

What are Rock Bolts Made of?

Rock bolts are typically made from high-strength steel, specifically designed to withstand the tensile forces required for ground support. The composition can vary based on the bolt type and its intended use, but the core element is almost always a durable steel rod or bar. For enhanced performance and longevity, these primary components can be combined with other materials.

Common materials used in rock bolt systems include:

- Plain Steel Rods: The most common and foundational material, providing the main tensile strength.

- Fiber-Reinforced Polymers (FRP): An alternative to steel, these composite materials are used when corrosion resistance or non-conductive properties are crucial.

- Grouting Agents: Materials like cement or resin are used to bond the bolt to the surrounding rock, ensuring a secure anchor.

- Protective Coatings: Zinc (galvanization) or other polymer coatings are applied to steel bolts to prevent corrosion in harsh, wet, or chemically aggressive environments.

Rock Bolt Design

Rock bolt design focuses on reinforcing rock masses to maintain stability in tunnels, slopes, and underground chambers. Engineers study geology, loads, and excavation geometry to determine spacing, length, anchorage, and bolt type.

A thoughtful design approach reduces deformation, increases safety, and keeps surrounding structures stable under changing stress conditions.

- Understanding Ground Conditions — Effective rock bolt design starts with analyzing joint spacing, fracture patterns, groundwater, and rock strength to anticipate how the ground will react under load and excavation stress, ensuring the chosen reinforcement performs predictably and prevents unexpected displacement throughout the full support zone.

- Selecting Bolt Type — Engineers choose mechanical, resin, friction, or self-drilling bolts by evaluating installation limits, load capacity, corrosion exposure, and ground quality, ensuring the reinforcement method matches field conditions and delivers dependable stability without creating delays or complications during the fastening or grouting process.

- Calculating Bolt Length — Bolt length is determined by identifying weakened rock layers, predicted shear zones, and stable anchorage points, extending the bolt far enough into competent rock to guarantee secure load transfer, reduce slippage risks, and maintain overall stability as excavation stresses change over time.

- Bolt Spacing and Pattern — Engineers design spacing and layout by evaluating expected deformation patterns, excavation size, and stress redistribution, creating a reinforcement grid that spreads loads evenly, strengthens weak areas, and maintains structural integrity while simplifying installation and achieving consistent performance across all supported sections.

- Evaluating Long-Term Performance — Long-term bolt efficiency depends on corrosion control, monitoring plans, environmental exposure, and load retention over time, ensuring the system continues performing as intended and minimizing maintenance needs while supporting the structure reliably through changing ground conditions and operational demands.

How Do Rock Bolts Work?

Rock bolts are a key component of ground support in mining, tunneling, and civil engineering, working as a type of reinforcement to stabilize rock masses. They are essentially long, steel rods inserted into pre-drilled holes in rock, then anchored in place with a mechanical or grouted bond. The primary function of a rock bolt is not to hold the rock up but to “stitch” together loose or fractured rock blocks.

By applying tension, they transfer the load from the unstable outer rock layers to the stronger, more stable inner rock mass, effectively creating a self-supporting arch or beam. This process, known as the Suspension Mechanism and the Beam Building Mechanism, prevents rockfalls and improves the overall integrity of the rock structure, ensuring safety and stability.

- Suspension Mechanism: The bolt acts like a nail, hanging a loose layer of rock on a more competent, stable layer above it.

- Beam Building Mechanism: By tensioning the bolts, they clamp together fractured layers of rock, creating a unified, strong beam that can support itself.

- Active Support: Rock bolts apply a pre-tensioned load to the rock mass, actively improving its strength and stability.

- Passive Support: Some bolts are not tensioned and only provide resistance when the rock mass starts to deform, offering support as needed.

- Reinforcement: They reinforce the rock mass itself, integrating loose blocks into a single, cohesive, and stronger structure.

Rock Bolt Types

Rock bolts come in a variety of types, each designed for specific applications and geological conditions. The choice of bolt depends on factors such as rock strength, ground stress, and project duration. Understanding these different types is key to effective and safe ground support.

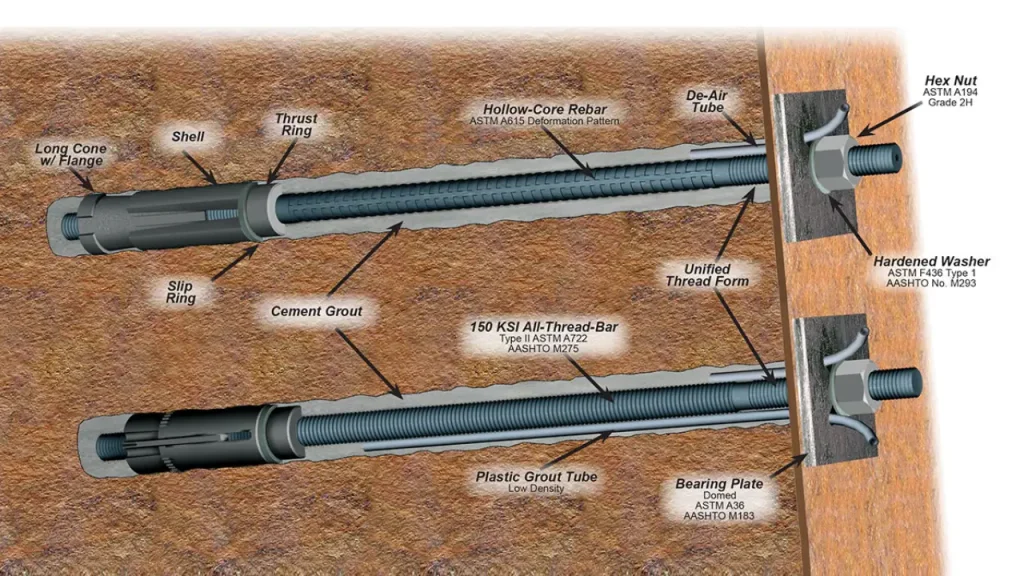

Mechanical Anchor Bolts

Mechanical anchor bolts are one of the most common types. They work by using a mechanical expansion shell at the end of the bolt. When the bolt is tightened, the shell expands, wedging itself firmly against the borehole wall. This creates a point anchor that transfers the load from the unstable rock face to the bolt, providing immediate support.

Grouted Rebar Bolts

Grouted rebar bolts are a passive system that relies on a bonding agent for stability. A steel rebar is inserted into a borehole, which is then filled with a cement or resin grout. Over time, the grout cures and creates a full-length bond between the bolt and the surrounding rock. This system is effective for long-term stability and is particularly useful in fractured rock masses.

Swellex Rock Bolts

Swellex rock bolts are an expandable, friction-based bolt. They consist of a folded steel tube that is inserted into a borehole. Using a high-pressure pump, water is injected into the bolt, causing it to expand and fill the entire borehole. This expansion creates a full-length friction and interlock with the rock, providing instant and reliable ground support without the need for grout.

Self-Drilling Anchor Bolts

Recommended Self-Drilling Anchor Bolts

-

R Thread Self Drilling Anchor Bars

-

T73 Self-Drilling Anchor Systems

-

T76 Self-Drilling Anchor Systems

-

T40 Self-Drilling Anchor Systems

-

T30 Self-Drilling Anchor Systems

-

T103 Self-Drilling Anchor Systems

-

T Thread Self Drilling Anchor Bars

-

R51 Self-Drilling Anchor Systems

-

R38 Self-Drilling Anchor Systems

Self-drilling anchor bolts are a versatile solution that combines drilling and bolting into a single operation. The hollow bolt acts as both the drill rod and the anchor, with a sacrificial drill bit at the tip. After drilling to the required depth, grout is pumped through the hollow bolt, which fills the borehole and secures the bolt in place, making it highly efficient in unstable ground.

How to Use Rock Bolts?

Properly installing rock bolts is crucial for ensuring their effectiveness and the safety of the entire ground support system. The process typically involves several key steps, each requiring precision and the right equipment to create a stable and lasting anchor.

Step 1: Drilling the Hole

The first step is to drill a borehole into the rock mass. The hole’s diameter must be slightly larger than the bolt itself to allow for installation. This is performed using a drilling rig and a rock drill bit, with the hole’s depth and angle carefully planned by engineers to achieve optimal support.

This is a critical preparatory step. The quality of the borehole, including its cleanliness and straightness, directly impacts the rock bolt’s final performance. A poorly drilled hole can compromise the bond between the bolt and the rock, reducing its load-bearing capacity and overall effectiveness.

Step 2: Preparing the Bolt

After drilling, the rock bolt and its components are prepared for insertion. This might involve assembling the bolt with a mechanical anchor shell or preparing the grouting materials like resin cartridges or cement grout. For expandable bolts, the bolt is simply prepped for the hydraulic pump connection.

This preparation ensures that all components are ready for a seamless installation. A clean bolt surface is essential for achieving a strong bond with the grouting agent, preventing any potential weak spots in the final anchor. Proper preparation saves time and enhances safety.

Step 3: Installing the Bolt

The bolt is then inserted into the prepared borehole. Depending on the bolt type, this step varies. For mechanical bolts, they are torqued to activate the anchor. For grouted bolts, the grout is injected or the resin cartridges are activated. For expandable bolts, water pressure expands them against the rock.

This is the final and most crucial step in the installation process. The correct application of force, torque, or pressure during installation is vital for creating a reliable anchor. A well-installed bolt will provide immediate or long-term support, effectively reinforcing the surrounding rock mass.

Rock Bolt Applications

Rock bolts are essential for a wide range of applications where ground stability is critical. They are used to reinforce rock masses and prevent them from unraveling, ensuring the safety and structural integrity of both temporary and permanent excavations. The application of rock bolts can be found across several major industries.

- Mining: Rock bolts are a fundamental component of ground support in underground mines, particularly in hard rock environments. They are used to stabilize the roofs and walls of mine shafts and tunnels, preventing rock falls and creating a safe working environment for miners.

- Tunneling: In the construction of tunnels for transportation, utilities, or water channels, rock bolts are used to reinforce tunnel walls and ceilings. They are often combined with other support systems like shotcrete and steel mesh to create a resilient structure that can withstand ground stress.

- Civil Engineering: Rock bolts are frequently employed to stabilize slopes, retaining walls, and deep excavations. They are a cost-effective method for controlling ground movement, making them valuable for projects like highway cuttings, urban excavations, and slope stabilization to prevent landslides.

- Hydroelectric Power: In the development of hydroelectric projects, rock bolts are crucial for stabilizing underground structures such as tunnels, penstocks, and turbine chambers. They ensure the long-term stability and safety of these critical infrastructure components.

Difference Between Rock Bolt and Rock Anchor

While the terms “rock bolt” and “rock anchor” are often used interchangeably, in engineering, they refer to different types of ground support systems, primarily distinguished by their function and how they are activated. A key difference lies in the load they are designed to handle and the way they are installed.

- Rock Bolts are generally considered a passive support system. They are typically installed at shallower depths to stabilize rock masses and prevent them from unraveling. They become “active” and begin to bear load only after the rock mass starts to deform or move. Their primary function is to “knit” together layers of rock to increase its overall strength and stability.

- Rock Anchors are an active support system. They are designed for greater depths and higher load capacities. Unlike rock bolts, they are “post-tensioned” after installation with a specific force using a hydraulic jack. This pre-tensioning creates a compressive force in the rock from the moment of installation, making them ideal for heavy-duty applications like stabilizing retaining walls, dams, and bridge abutments.

Conclusion

In conclusion, rock bolts are a cornerstone of modern ground support technology. Their ability to reinforce rock masses by applying tension and creating a self-supporting arch is fundamental to the safety and longevity of underground and surface projects. From passive friction bolts to active cable bolts, the variety of rock bolt types ensures that there is an effective solution for virtually any geological condition and engineering challenge.

Choosing the correct rock bolt is a critical decision that impacts the safety and cost-effectiveness of your project. Factors such as the rock type, stress conditions, and the intended lifespan of the structure must all be considered. Understanding the differences between mechanical, chemical, and expandable bolts allows for a tailored and highly effective ground support strategy.

For your next project, remember to prioritize quality and reliability. At Sinodrills, we offer wholesale rock bolts and a full range of drilling tools designed to meet the highest industry standards. Contact us today to get wholesale rock bolts and find the perfect ground support solution for your needs.