Have you ever wondered what makes certain drill bits capable of tackling the toughest materials with ease? The answer often lies in a remarkable material: tungsten carbide. These specialized bits are engineered for superior performance, offering unparalleled durability and efficiency when standard drill bits simply won’t suffice.

This blog post will delve into the world of tungsten carbide bits, explaining what they are and what sets them apart. We’ll explore their unique composition, the properties that make them so effective, and why they have become an indispensable tool across various industries, from construction to manufacturing.

What is Tungsten Carbide?

Tungsten carbide (WC) is a chemical compound primarily composed of equal parts tungsten and carbon atoms, forming a remarkably dense and hard material. In its most basic form, it appears as a fine gray powder, but it’s most commonly known in its sintered, solid form, often combined with a metallic binder like cobalt or nickel to create “cemented carbide.”

This binder enhances its toughness and ductility while retaining the extreme hardness and wear resistance that make tungsten carbide second only to diamond on the Mohs scale.

Its exceptional properties, including high melting point, superior compressive strength, and resistance to deformation even at elevated temperatures, make it an indispensable material for demanding applications such as cutting tools, drill bits, industrial machinery parts, and wear-resistant components.

What is a Tungsten Carbide Bit?

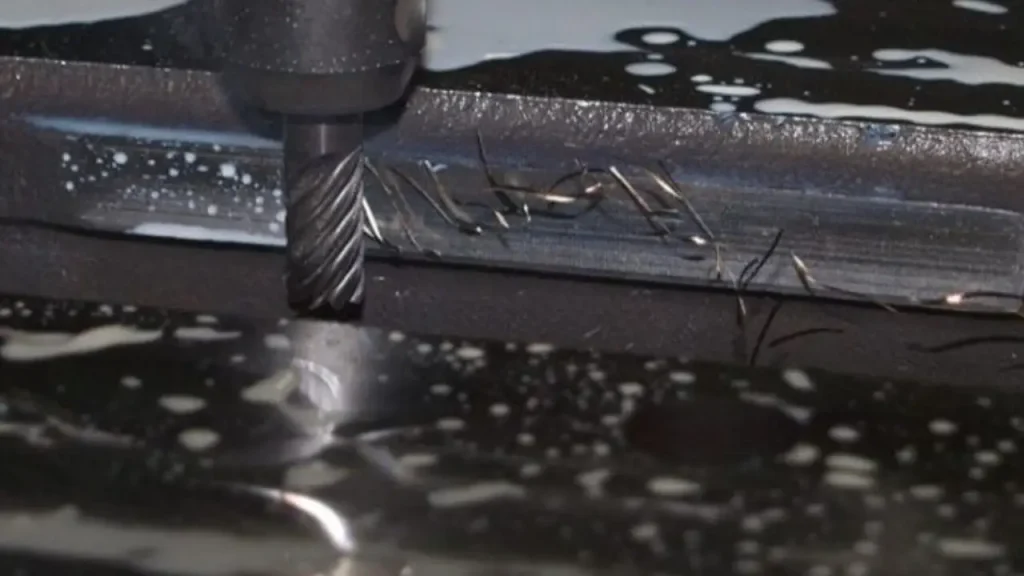

A tungsten carbide bit is a highly durable and specialized cutting tool that features a tip or is entirely composed of tungsten carbide, a composite material known for its exceptional hardness and resistance to wear. This material, formed by combining tungsten and carbon atoms, is significantly harder than steel and can withstand extreme temperatures and pressures.

Tungsten carbide bits are indispensable for drilling, cutting, and shaping tough materials such as hardened steel, concrete, masonry, cast iron, and even some ceramics, making them a preferred choice in demanding industrial applications like construction, manufacturing, and mining where precision, efficiency, and longevity are crucial.

Why Choose Tungsten Carbide for Drill Bits?

Tungsten carbide is the material of choice for drill bits designed to tackle the toughest applications due to its unparalleled properties, which significantly outperform traditional high-speed steel (HSS) bits. This remarkable performance stems from several key advantages:

- Exceptional Hardness: Tungsten carbide boasts an incredibly high hardness, ranking just below diamonds on the Mohs scale. This extreme hardness allows the drill bit to maintain a sharp cutting edge, even when drilling through abrasive and difficult materials like hardened steel, concrete, and rock, reducing wear and extending tool life.

- Superior Wear Resistance: Dueating to its inherent toughness, tungsten carbide is highly resistant to abrasion and erosion. This means the bits can endure prolonged use in demanding conditions without losing their cutting efficiency, leading to fewer tool changes and increased productivity.

- High Heat Resistance: Drilling through hard materials generates significant heat. Unlike HSS, tungsten carbide retains its hardness and cutting integrity even at elevated temperatures, enabling faster drilling speeds and continuous operation without compromising performance or causing premature dulling.

- Enhanced Precision and Longevity: The combination of hardness and wear resistance allows tungsten carbide bits to produce precise, clean holes consistently. Their extended lifespan translates to greater cost-effectiveness in the long run, as fewer replacements are needed and downtime is minimized.

Tungsten Carbide Bit Types for Rock Drilling

Tungsten carbide bits are essential tools in rock drilling, known for their exceptional hardness and wear resistance. They are designed to withstand the abrasive forces encountered during drilling operations, making them highly effective in various geological formations. The choice of tungsten carbide bit type depends heavily on the specific rock properties and drilling conditions, ensuring optimal performance and longevity.

Chisel Tungsten Carbide Bits

A chisel tungsten carbide bit, characterized by its wedge-shaped tungsten carbide inserts, is particularly effective in drilling soft to medium-hard rock formations. Its design allows for efficient crushing and breaking of the rock, making it suitable for applications where penetration rate is a priority. These tungsten carbide bits are commonly used in mining, quarrying, and construction for tasks like blastholing and tunneling.

Cross Tungsten Carbide Bits

A cross tungsten carbide bit features two perpendicular wings with tungsten carbide inserts, providing a more balanced and robust cutting action. This tungsten carbide bit design makes it well-suited for drilling in medium to hard rock, offering good directional stability and a longer service life compared to chisel bits in such conditions. They are often employed in demanding drilling operations where consistent performance is crucial.

Button Tungsten Carbide Bits

A button tungsten carbide bit is equipped with multiple spherical or conical tungsten carbide inserts (buttons) arranged in various patterns. These tungsten carbide bits excel in very hard and abrasive rock formations due to their superior wear resistance and ability to absorb impact forces. The button design promotes a rolling and crushing action, which minimizes wear on the bit face and extends its operational life, making them popular in demanding percussive drilling applications.

Retrac Tungsten Carbide Bits

A retrac tungsten carbide bit is a specialized type, often incorporating button inserts, designed with a unique skirt or body shape that facilitates easier retraction from the drill hole, especially in fractured or unstable ground. This tungsten carbide bit’s design helps prevent it from getting stuck, improving drilling efficiency and reducing downtime in challenging geological conditions. They are particularly valuable in civil engineering and foundation drilling where hole stability is a concern.

Drop-Center Tungsten Carbide Bits

A drop-center tungsten carbide bit features a recessed center portion, which helps to create a pilot hole and maintain better hole straightness, especially in uneven or fractured rock. The design of this tungsten carbide bit promotes a more centralized impact, reducing deviation and ensuring a more accurate bore. These bits are often preferred for precision drilling applications where maintaining a true and straight hole is critical for subsequent operations.

Reaming Tungsten Carbide Bits

A reaming tungsten carbide bit is designed not for initial drilling, but for enlarging existing drill holes to a larger diameter. This tungsten carbide bit typically features a robust body with strategically placed tungsten carbide inserts that efficiently grind away the rock around the pilot hole. These bits are essential in operations requiring larger boreholes for casing, anchors, or other installations, ensuring a smooth and consistent enlargement process.

Pilot-Adapter Tungsten Carbide Bits

A pilot-adapter tungsten carbide bit is not a standalone drilling bit but is designed to work in conjunction with larger reaming or hole-opening tools. It features a smaller diameter section that acts as a pilot, guiding the larger reamer through the initial hole. This combination, utilizing a pilot-adapter tungsten carbide bit, allows for efficient and accurate enlargement of holes, particularly in situations where a precise initial bore is followed by a significant increase in diameter.

Tungsten Carbide Bit Benefits

Tungsten carbide bits offer a multitude of benefits that make them indispensable for demanding drilling applications. Their exceptional hardness ensures they maintain a sharp cutting edge, allowing for superior precision and cleaner holes even when working with the toughest materials.

This inherent durability translates to significantly longer tool life compared to conventional drill bits, reducing the frequency of replacements and minimizing costly downtime in industrial settings. Furthermore, their high heat resistance allows for faster drilling speeds and continuous operation without compromising performance, boosting overall productivity.

The stability and rigidity of tungsten carbide also lead to less vibration and wobble during drilling, contributing to improved accuracy and surface finish. In essence, while the initial investment might be higher, the long-term cost-effectiveness, enhanced performance, and reliability of tungsten carbide bits provide significant advantages for professionals across various industries.

- Extended Tool Life: Significantly outlasts traditional drill bits due to extreme hardness and wear resistance.

- Superior Cutting Performance: Maintains a sharp edge for precise, clean, and efficient drilling.

- High-Speed Drilling: Withstands high temperatures, allowing for faster operational speeds.

- Increased Productivity: Fewer tool changes and faster cutting speeds lead to improved workflow and output.

- Enhanced Accuracy and Finish: Reduces vibration and produces more precise holes with better surface quality.

- Cost-Effectiveness: Despite a higher upfront cost, long-term savings are realized through reduced replacements and increased efficiency.

How to Choose Suitable Tungsten Carbide Bits for Rock?

Choosing the right tungsten carbide bit for rock drilling is crucial for maximizing efficiency and minimizing costs. The optimal bit depends heavily on the specific geological conditions and your drilling objectives. Understanding the various types and their suitability for different rock formations is paramount.

- Rock Hardness and Abrasiveness: This is the primary factor. Softer, less abrasive rocks might allow for bits with more aggressive cutting structures (e.g., chisel inserts), while extremely hard and abrasive rocks demand tougher, more wear-resistant designs (e.g., spherical button bits).

- Drilling Method and Equipment: The type of drill rig (e.g., top hammer, DTH) and its capabilities will dictate the compatible bit connection type and influence the recommended bit design.

- Desired Penetration Rate vs. Bit Life: There’s often a trade-off between how fast you can drill and how long the bit will last. More aggressive designs typically offer higher penetration rates but may have a shorter lifespan in very hard rock.

- Hole Diameter and Depth: The required hole size and depth will influence the overall bit dimensions and design, including the number and arrangement of carbide inserts.

- Presence of Fissures or Fractures: For fractured or broken rock, certain bit designs, like cross bits, might offer better stability and performance.

Conclusion

In conclusion, tungsten carbide bits are truly a game-changer in the world of drilling and machining. Their exceptional hardness, wear resistance, and ability to withstand high temperatures make them indispensable for working with materials that would quickly degrade conventional tools. Understanding their unique properties and proper application is key to achieving optimal results and extending tool life in demanding environments.

The versatility of tungsten carbide bits means they are utilized in a vast array of applications, from precision drilling in aerospace to heavy-duty rock excavation. Their enduring performance ensures higher efficiency, reduced downtime, and ultimately, a more cost-effective solution for challenging drilling tasks. Investing in quality tungsten carbide tools is an investment in productivity and precision.

For those seeking reliable and high-performance tungsten carbide drill bits for rock drilling, look no further. Sinodrills offers a comprehensive range of wholesale tungsten carbide drill bits designed to meet the rigorous demands of your projects. Contact us today to learn more about our durable and efficient solutions for all your drilling needs.