Drill pipe forms the critical backbone of any rotary drilling operation, connecting the surface rig components to the drill bit at the bottom of the borehole. Far more than just a simple tube, this engineered component transmits rotational torque, delivers drilling fluid, and withstands immense axial loads and vibrations.

Understanding the intricacies of drill pipe – from its construction to its varied specifications – is essential for ensuring efficient, safe, and productive drilling. This guide will delve into everything you need to know about these indispensable drilling pipes.

What is a Drill Pipe?

Recommended Drill Pipes

A drill pipe is a heavy, seamless steel tube that is a fundamental component of a drill string in rotary drilling operations, primarily used in oil and gas, geothermal and water well drilling.

It serves multiple critical functions: transmitting rotational torque from the drill rig to the drill bit, providing a conduit for the circulation of drilling fluid (mud) to cool the bit and carry cuttings to the surface, and withstanding significant tensile, compressive, and torsional stresses.

Drill pipes are manufactured in standard lengths and connected by threaded tool joints, allowing for the extension of the drill string as the well deepens.

What is a Drill Pipe Used For?

A drill pipe is a multi-functional component critical to rotary drilling, serving several essential purposes in transferring power and materials downhole:

- Transmitting Rotary Power: It connects the drill bit to the surface rotary table or top drive, transferring the rotational torque needed to turn the bit and cut through rock.

- Circulating Drilling Fluid: It acts as a conduit for drilling fluid (mud) to be pumped down to the drill bit, where it cools and lubricates the bit, and then carries rock cuttings back to the surface.

- Applying Weight on Bit (WOB): While drill collars primarily provide WOB, the drill pipe also contributes to the total weight and helps to maintain the necessary downward force on the drill bit for effective penetration.

- Supporting Downhole Tools: The drill pipe string supports the weight of the drill collars, the drill bit, and other bottom-hole assembly (BHA) components.

- Facilitating Wireline and Logging Operations: It can provide a pathway for running wireline tools and logging instruments into the borehole to gather data about the geological formations.

What Materials Are Used in Drill Pipes?

A drill pipe is predominantly manufactured from steel, specifically high-strength, low-alloy steel (HSLA). This material is chosen for its exceptional ability to endure the severe conditions encountered during drilling, such as immense stress, corrosive environments, and abrasive wear.

- High-Strength, Low-Alloy Steel (HSLA): This is the primary material due to its robust mechanical properties, allowing it to withstand high tensile, compressive, and torsional stresses inherent in drilling operations. It offers the necessary strength and fatigue resistance to operate effectively in demanding downhole environments.

- Aluminum: Occasionally, aluminum drill pipes are utilized, particularly in applications where reducing weight is a critical concern. Its lighter weight can decrease the load on the drilling rig and potentially allow for deeper drilling with less power.

- Corrosion-Resistant Coatings: To provide additional protection against corrosion, especially in aggressive drilling fluids or environments, drill pipes may be coated with materials such as nickel or other specialized anti-corrosion coatings. These coatings extend the life of the pipe and reduce the risk of material degradation.

What Is a Drill String?

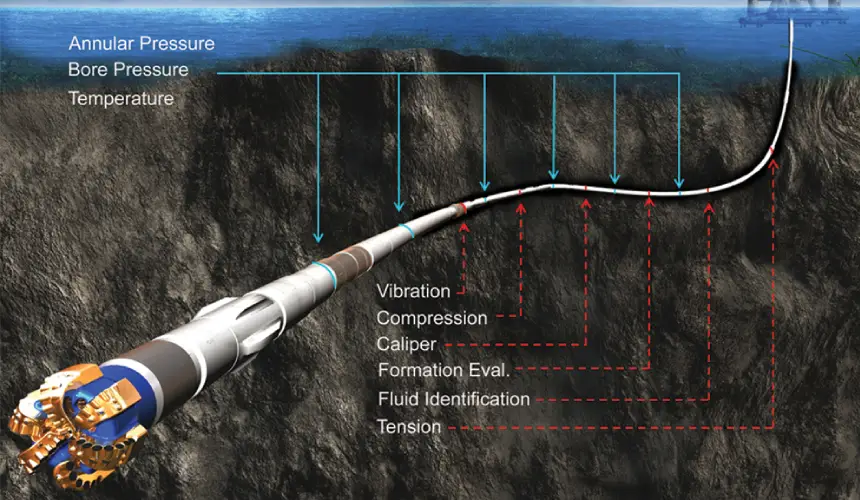

A drill string is the complete assembly of drilling tools that extends from the surface drilling rig down into the wellbore, connecting the rotary power source to the drill bit.

It is primarily composed of drill pipe, which makes up the majority of its length, along with heavier drill collars located just above the bit to provide weight and rigidity, and various specialized bottom-hole assembly (BHA) components such as stabilizers, reamers, and measurement-while-drilling (MWD) tools.

The drill string’s main function is to transmit rotational torque to the drill bit, allow for the circulation of drilling fluid, and provide the necessary weight and stability for efficient and controlled drilling operations.

Drill Pipe Types

Drill pipes are engineered components crucial for transmitting power and materials downhole in various drilling operations. Their specific design and material properties are tailored to meet the rigorous demands of different drilling environments and objectives, ensuring both efficiency and safety throughout the process.

Regular Drill Pipe

Regular drill pipes are the most common type, forming the bulk of the drill string. These are standard-weight pipes designed for general drilling applications, providing the necessary strength for rotation and fluid circulation while supporting downhole tools.

Heavyweight Drill Pipe

Heavyweight drill pipes (HWDP) are thicker and heavier than regular drill pipes, typically placed in the transition zone between the drill collars and the drill pipe. They help provide additional weight on bit and increase the stiffness of the drill string, aiding in smooth drilling and reducing fatigue failures.

Spiral Pipes

Spiral pipes feature spiral grooves on their outer surface. These grooves are designed to reduce differential sticking, a common problem where the drill pipe becomes stuck against the borehole wall due to pressure differences. The spiral design helps to minimize contact area and improve mud flow around the pipe, facilitating enhanced torque transmission.

Specialty Pipes

Specialty pipes are customized for specific drilling challenges, particularly in directional and horizontal drilling. These can include pipes with unique internal coatings, advanced metallurgy for corrosive environments, or specific connection types to handle complex well paths and severe bending stresses encountered in highly deviated wells.

Drill Pipe Classification

Drill pipes are categorized based on their condition and remaining service life, a crucial classification for operational safety and efficiency in drilling. This ensures that the right pipe is selected for the demanding conditions encountered downhole.

N-Class (New Pipe)

These are the newest and strongest drill pipes available, typically in excellent or near-pristine condition. N-Class pipes offer maximum strength and reliability for the most demanding drilling applications, representing the highest quality in the inventory and providing optimal performance.

P-Class (Premium Pipe)

Premium pipes have experienced some wear from previous use but remain highly functional. They undergo rigorous inspection to ensure they still meet strict performance criteria, making them a cost-effective choice for many drilling operations where new pipe isn’t strictly necessary, balancing cost with performance.

C-Class (Used Pipe)

C-Class pipes are subdivided into C-1, C-2, and C-3, reflecting increasing levels of wear and reduced service life. C-1 pipes are still usable but more worn than P-Class, while C-3 pipes are nearing the end of their serviceable life and are often relegated to less critical roles or identified for scrap.

How to Measure Drill Pipe Size?

How to Measure Drill Pipe Size

Accurately measuring drill pipe size is crucial for ensuring compatibility, proper operation, and safety on the drilling rig. Incorrect measurements can lead to equipment failure, reduced efficiency, or even serious accidents. This guide outlines the key steps involved in precisely measuring drill pipe dimensions.

Step 1: Measure Outer Diameter (OD)

The Outer Diameter (OD) is a fundamental measurement of the drill pipe body. Use a large caliper or a pipe tape measure to get an accurate reading across the pipe’s exterior, perpendicular to its length. This measurement, typically expressed in inches, dictates the pipe’s clearance within the wellbore and its compatibility with other drilling tools and casing sizes.

Step 2: Measure Wall Thickness

Wall thickness is vital for understanding the pipe’s strength and pressure rating. This is usually measured using an ultrasonic thickness gauge or by inspecting the pipe’s cut end. A greater wall thickness generally indicates higher burst and collapse resistance, allowing the pipe to withstand more extreme downhole pressures and stresses encountered during drilling operations.

Step 3: Measure Inner Diameter (ID)

The Inner Diameter (ID) of the drill pipe affects the flow rate of drilling fluid and the passage of downhole tools. Measure the internal dimension using a suitable internal caliper or by calculation (OD – 2 * Wall Thickness). A larger ID allows for more efficient fluid circulation, reducing pressure losses and improving the hydraulic performance of the drilling system.

Step 4: Measure Tool Joint OD and ID

Tool joints are the threaded connections at each end of the drill pipe. Measure their Outer Diameter (OD) using a caliper, noting that it’s typically larger than the pipe body OD for strength. Measure the Inner Diameter (ID) of the tool joint bore to ensure smooth passage of drilling fluid and any internal tools, as constrictions here can impede flow.

Step 5: Measure Tool Joint Length

Tool joint length refers to the total length of the male (pin) and female (box) connections. Measure from the shoulder of the pipe body to the end of the tool joint. This dimension is important for calculating the overall length of each drill pipe stand and for determining the space required for racking and handling on the drill floor.

Step 6: Measure Upset Type and Length

The upset is a thickened section of the pipe body near the tool joint, providing extra material for threading and strength. Identify if it’s an internal (IU), external (EU), or internal-external (IEU) upset. Measure its length and diameter to ensure it matches specifications for stress distribution and connection integrity.

Step 7: Inspect Thread Type and Connection (API)

Finally, verify the thread type and connection profile against API (American Petroleum Institute) standards. This involves checking the thread form, pitch, and taper using specialized gauges. Correct thread type (e.g., NC, FH) and connection ensure a secure, pressure-tight seal and efficient torque transmission between individual pipe joints, preventing costly failures.

Importance of Drill Pipe Maintenance

The diligent maintenance of drill pipe is paramount to ensuring safe, efficient, and cost-effective drilling operations. Neglecting maintenance can lead to catastrophic failures, costly downtime, and significant safety hazards on the rig. Proper care extends the life of valuable assets and optimizes performance.

Ensuring Safety:

Regular inspections identify defects like cracks or corrosion before they lead to catastrophic failures. This prevents pipe parting downhole, which can cause severe accidents, injury to personnel, and extensive equipment damage, prioritizing the well-being of the crew.

Maximizing Lifespan:

Proper cleaning, inspection, and protective coating application prevent wear and corrosion. This significantly extends the service life of drill pipes, delaying the need for costly replacements. Maximizing lifespan translates directly into substantial long-term cost savings for drilling contractors.

Optimizing Drilling Performance:

Well-maintained drill pipe with clean threads and proper connections ensures efficient torque transmission and smooth drilling fluid flow. This maximizes penetration rates and reduces unwanted vibrations, leading to more productive drilling, faster well completion, and improved overall operational efficiency.

Reducing Non-Productive Time (NPT):

Proactive maintenance minimizes unexpected failures and sticking events downhole. This drastically reduces costly non-productive time (NPT) associated with fishing operations, lost circulation, or pipe replacements, keeping drilling projects on schedule and within budget.

Preventing Costly Failures:

Early detection of wear, fatigue, or damage through routine maintenance avoids major failures. Preventing a pipe rupture or tool joint wash-out can save hundreds of thousands to millions of dollars in repair costs, lost revenue, and environmental cleanup, protecting financial investments.

Conclusion

In conclusion, the drill pipe is an indispensable component in rotary drilling, a precision-engineered conduit that transfers power, fluid, and critical information from the surface to the drill bit. Its design, material, and maintenance are paramount to drilling efficiency, safety, and project success.

Understanding the various types, specifications, and selection criteria for drill pipes empowers drilling professionals to make informed decisions that optimize performance and minimize operational risks. The right drill pipe ensures that every rotational force and every gallon of drilling fluid precisely reaches its target.

For reliable drill pipes that meet the rigorous demands of your drilling projects, consider sourcing wholesale drill pipes from Sinodrills.